COMPACFOAM in yacht building – lightweight construction without compromise

Moisture-resistant, dimensionally stable and screwable – the innovative core material for modern yacht building

The alternative – weight saving, stability and durability.

Request nowscrewable

SALT WATER RESISTANT

70% lighter than wood

Screwable without pre-drilling

Dimensionally stable

isotropic

Open to diffusion

Insensitive to moisture

highly resilient

light

Formaldehyde-free

recyclable

screwable

SALT WATER RESISTANT

70% lighter than wood

Screwable without pre-drilling

Dimensionally stable

isotropic

Open to diffusion

Insensitive to moisture

highly resilient

light

Formaldehyde-free

recyclable

Applications in yacht building

Interior fittings

Furniture and furnishings

Sandwich panels for cupboards, tables and bunks

Lightweight partition walls and room dividers

Floor structures with integrated insulation

Ceiling constructions

Advantages:

Direct screwing of fittings without dowels

No deflection

Can be coated with HPL, veneer or laminate

Repairable in case of damage

Hull construction

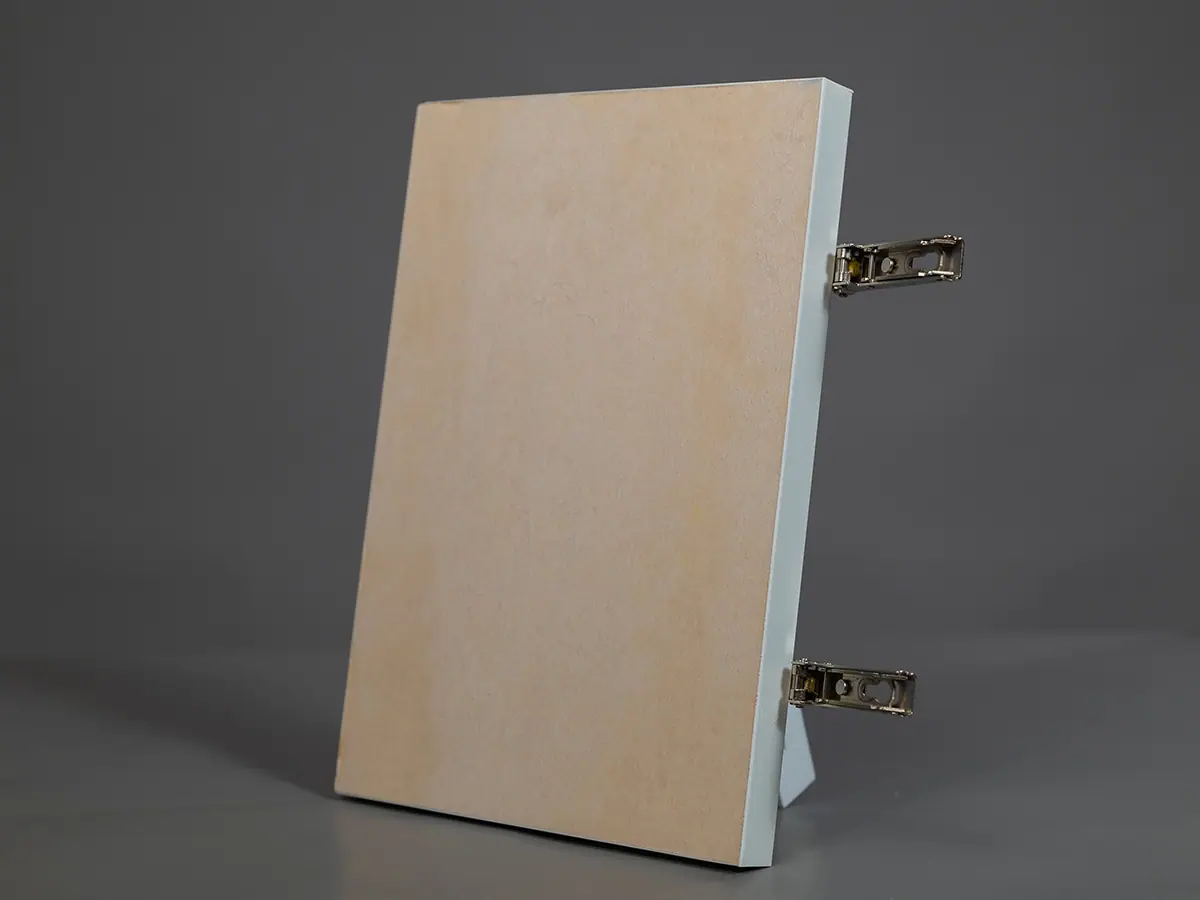

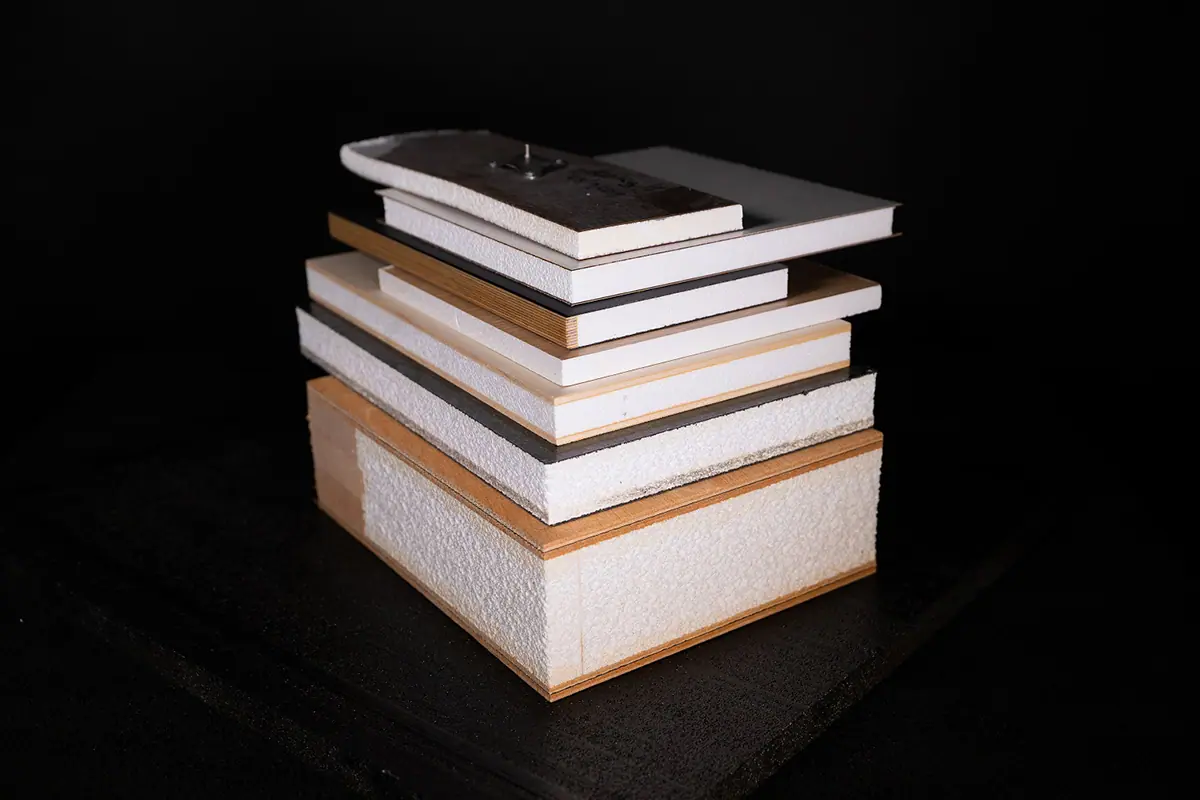

Sandwich construction

Core material for GRP sandwich structures

Bulkheads and reinforcing structures

Mast foundations and fitting fixings

Cockpit and deck superstructures

Vorteile:

Excellent peeling force transmission

Outstanding dimensional stability

Direct screwing without dowels

Dimensionally stable up to 90°C

Comparison with traditional materials

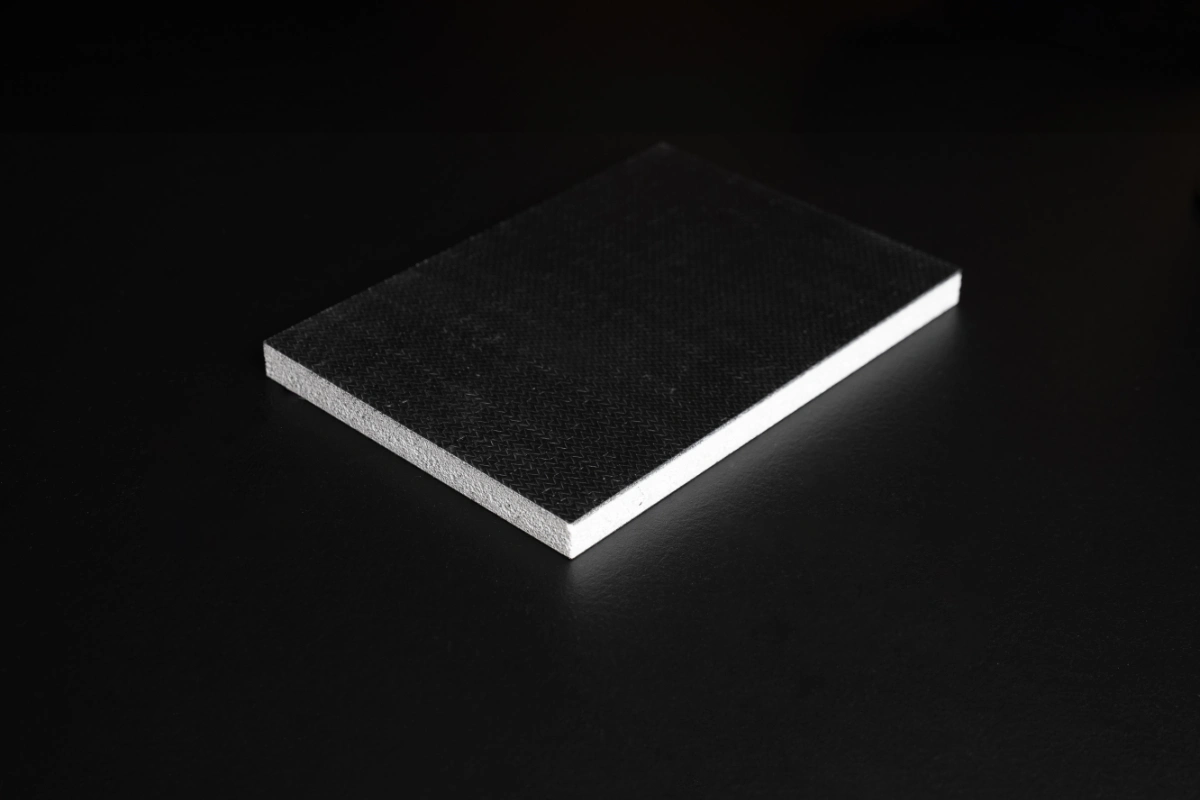

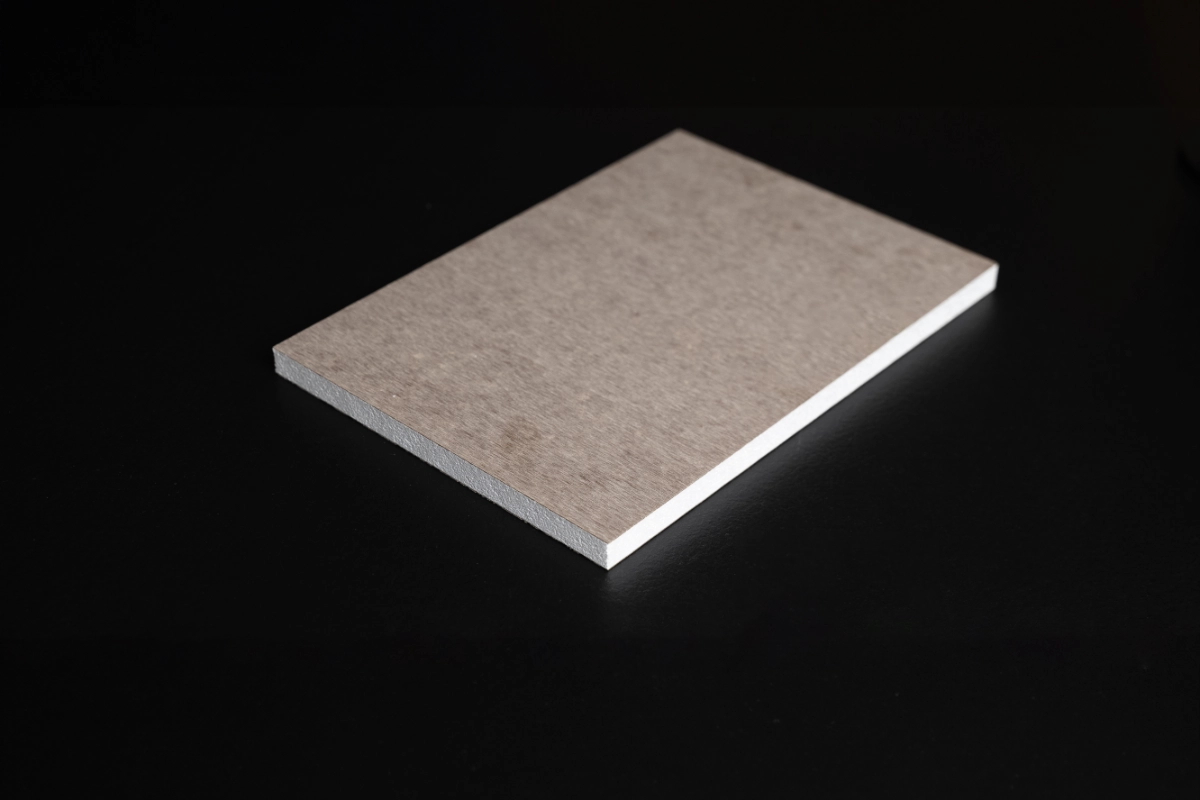

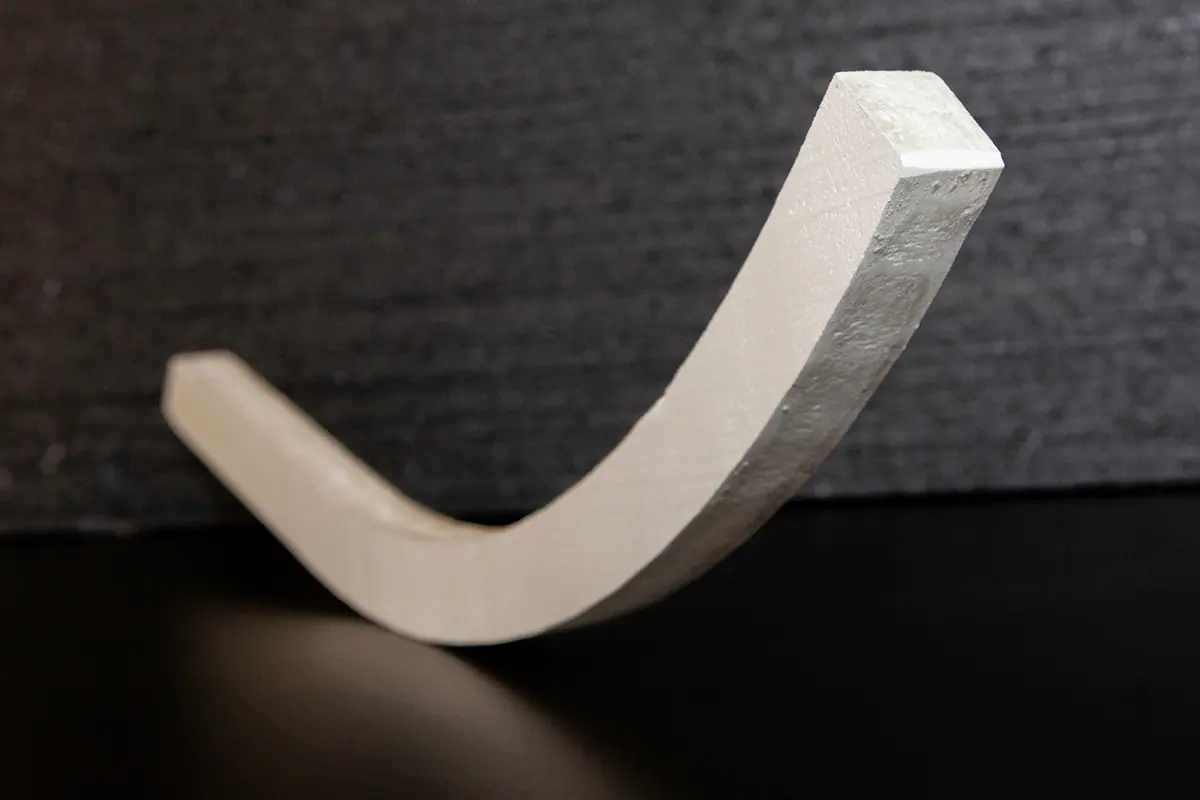

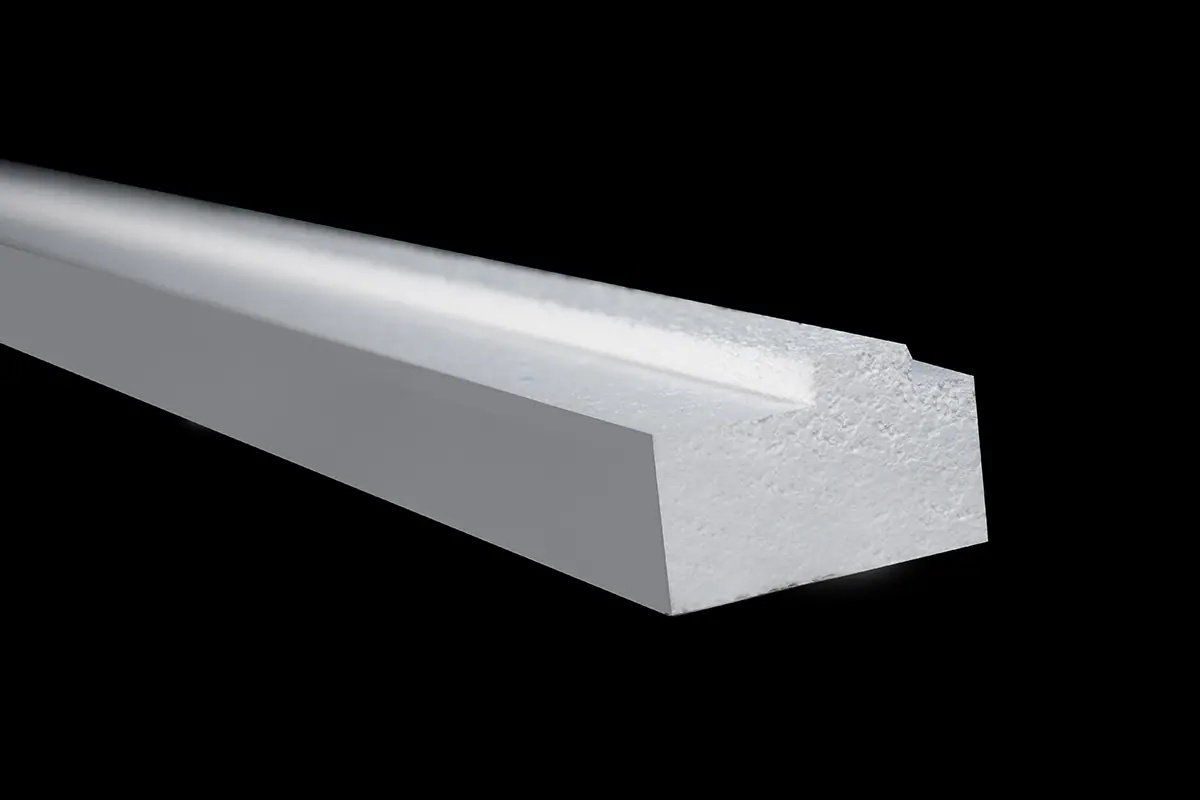

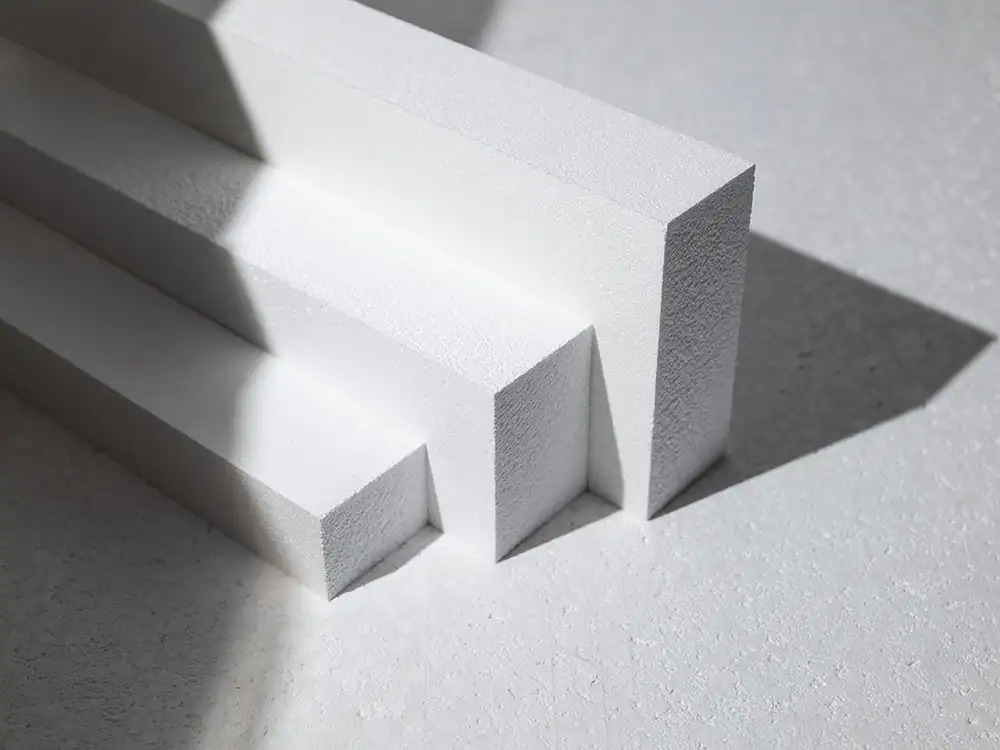

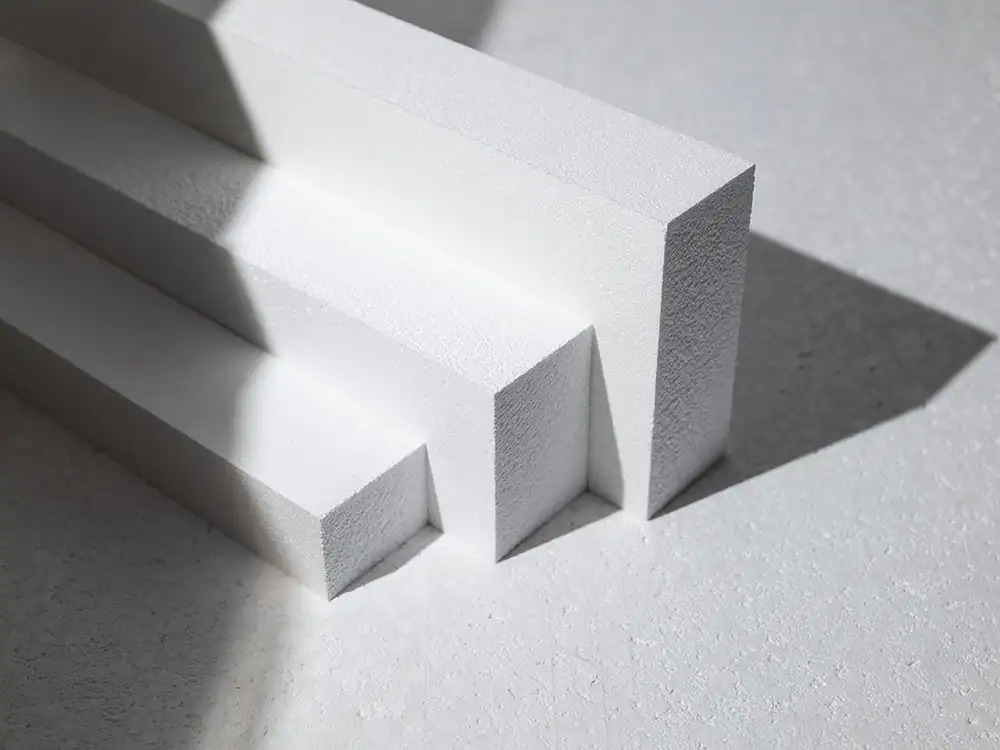

COMPACFOAM combines strength with excellent thermal insulation and low weight. As a flexible construction element and high-quality insulating material, it is versatile and easy to work with standard woodworking machines (screwing, drilling, sawing, planing, milling).

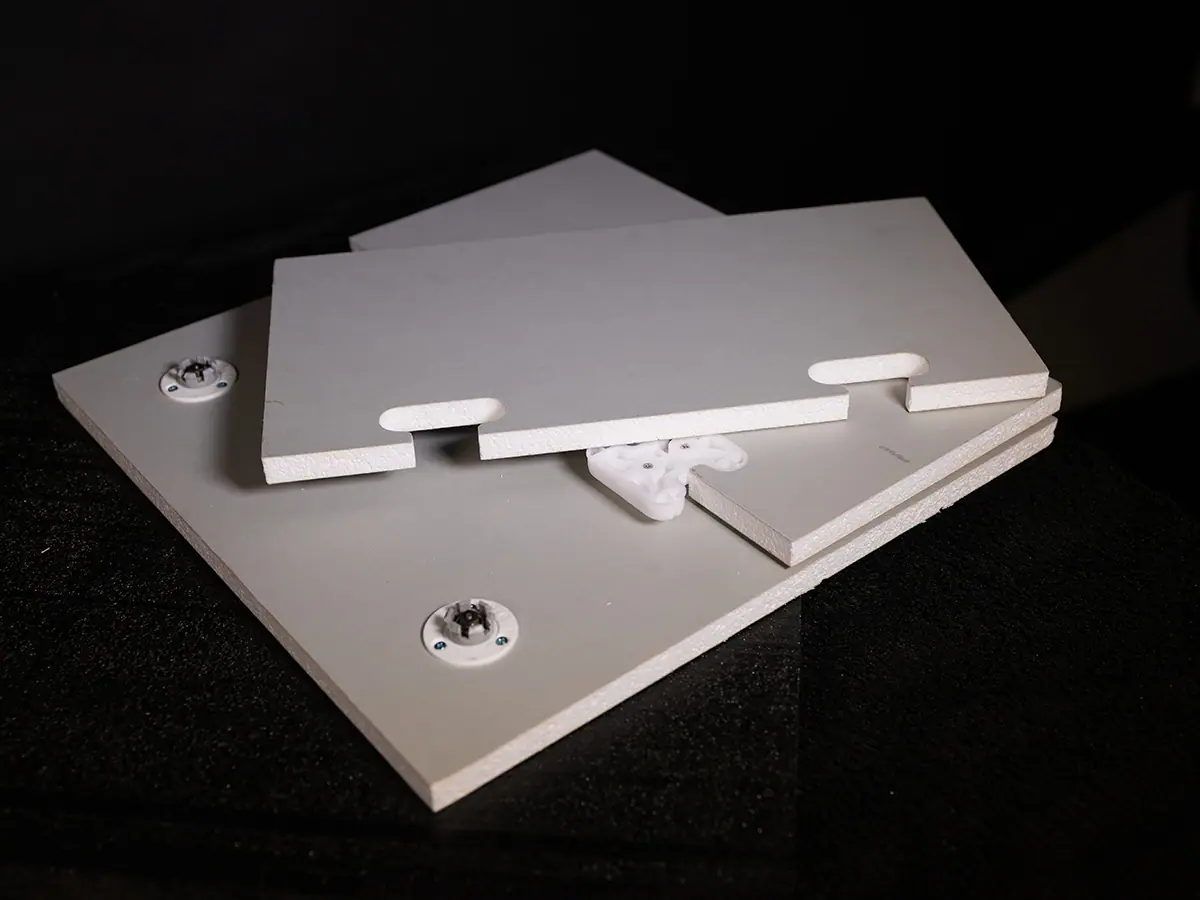

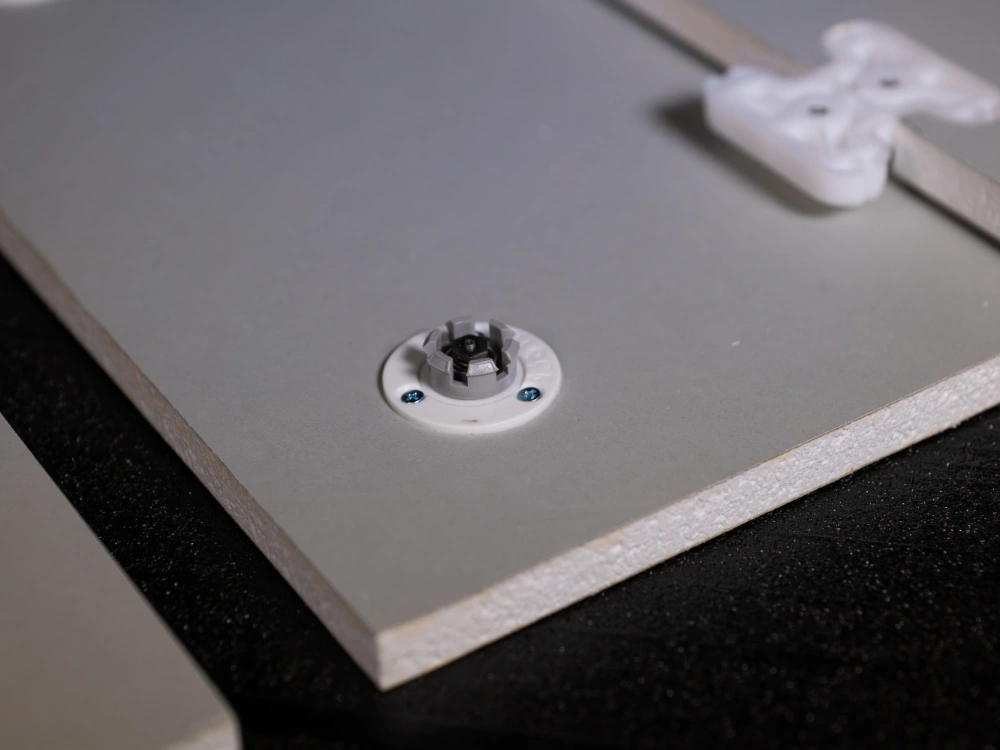

The material enables screw connections with standard wood screws without pre-drilling and achieves high pull-out forces. COMPACFOAM is customizable in thickness and dimensions – a decisive advantage for projects with different cover layer requirements. The use of standard furniture hardware is possible without any problems. The material is moisture-resistant, temperature-stable up to 90°C and is characterized by high resistance to ageing and decay. COMPACFOAM does not swell or shrink, so that it remains permanently reliable.

Available as a sandwich panel, panel, bar or profiled bar in standard formats and customized cuts according to customer specifications. COMPACFOAM is recyclable and sustainable.

A modern construction material for yacht building

Test COMPACFOAM in your project

Convince yourself of the properties of our construction materials. Order sample panels in 1210x610mm format – ideal for testing screwability, cutting and processing properties in your vehicle construction project.

Fast delivery:

Your sample panels will be delivered directly to your workshop or office within a few days. Pay conveniently by credit card, PayPal or EPS.

Choose from different COMPACFOAM variants

the right material thickness and surface for your application. This allows you to find the optimum solution for your vehicle project even before placing a bulk order.

Data sheets

Areas of application in yacht building

Greatest savings potential – removal weight

Furniture construction offers the greatest potential for reducing the weight of sailing yachts.

COMPACFOAM is the easy-to-process core material for lightweight sandwich structures in interior construction. It saves weight, remains dimensionally stable and is permanently resistant to salt water. You process COMPACFOAM with the same tools and methods as wooden panels.

Milling, sawing, screwing and gluing work without any problems. The material does not warp when exposed to moisture or temperature – for the longevity of the construction.

Request sample material nowTypical applications on board:

In use, shipyards benefit from simple integration: The same fitting systems can be used as in conventional furniture construction. Reinforcements are not required.

Normal furniture edges can also be applied. Compared to plywood COMPACFOAM weight and moisture absorption. Compared to PVC or PUR foam, the main advantage is the absence of warping – the panels remain permanently straight.

High dimensional stability & reduced weight

The material enables large-scale furniture components with high dimensional stability and reduced weight – without compromising on comfort or appearance.

COMPACFOAM is the lightweight construction material for fine furniture in yacht building, combining weight advantages with lasting dimensional stability.

Processing is the same as for wooden panels: milling, sawing, gluing and screwing are all possible with standard tools.

Even with changing temperatures and humidity, the components remain warp-free. This means that fronts, sideboards and built-in units retain their perfect appearance in the long term.

Request sample material nowTypical applications on board:

Decorative surfaces and visible edges can be processed without any problems.

Compared to plywood, the construction weight is significantly lower: Compared to PVC or PUR foam COMPACFOAM due to absolute dimensional stability – the panels remain straight, even with large components.

Another advantage: The material is free from formaldehyde and other outgassing – a plus for healthy interiors.

Reduced weight & maximum dimensional stability

Lightweight, stable partition walls are crucial for a functional room layout on board.

COMPACFOAM is the core material for yacht construction that reduces weight while offering maximum dimensional stability.

The panels remain undistorted even with changing humidity or temperature. This eliminates the need for reworking due to deformation – a clear advantage in the interior fitting of sailing yachts, even with very large elements.

Its excellent insulating effect against heat and cold helps to prevent condensation in cabins and storage spaces.

The material is free of formaldehyde and other outgassing, which contributes to healthy interiors.

Request sample material nowTypical applications on board:

Processing is carried out using standard wood tools, which makes installation easier. The panels are available in excess lengths and special widths according to customer requirements – ideal for impact-free constructions. The panel thickness is adjusted exactly to the required wall thickness.

Due to the high strength of the core panels, only very thin and light surfaces need to be applied.

This saves weight and costs.

In comparison to conventional wooden panels is COMPACFOAM significantly lighter and also moisture-resistant. PVC or PUR foam boards have a tendency to warp. COMPACFOAM remains straight and dimensionally stable.

High load capacity – low weight

Dimensionally stable materials are crucial for switchgear, control stations and supply system cladding.

COMPACFOAM is the construction material for maritime use that combines high load-bearing capacity with low weight. The panels remain absolutely dimensionally stable even with changing temperatures, vibrations and moisture.

This ensures that sensitive technical areas function reliably. Thanks to the high strength, very thin and light cover layers can be applied – this saves weight and costs.

Request sample material nowTypical applications on board:

A special advantage lies in its precise machinability: COMPACFOAM is ideal for use on CNC milling machines. Cut-outs for displays, ventilation slots, switches or cable ducts can be produced precisely and with repeat accuracy. The panels are also easy to screw together using standard wood screws – without any reinforcing elements.

In comparison to conventional wooden panels is COMPACFOAM significantly lighter and also resistant to moisture. PVC or PUR foam boards tend to

to deformation, while COMPACFOAM remains straight and stable – even with temperature differences.

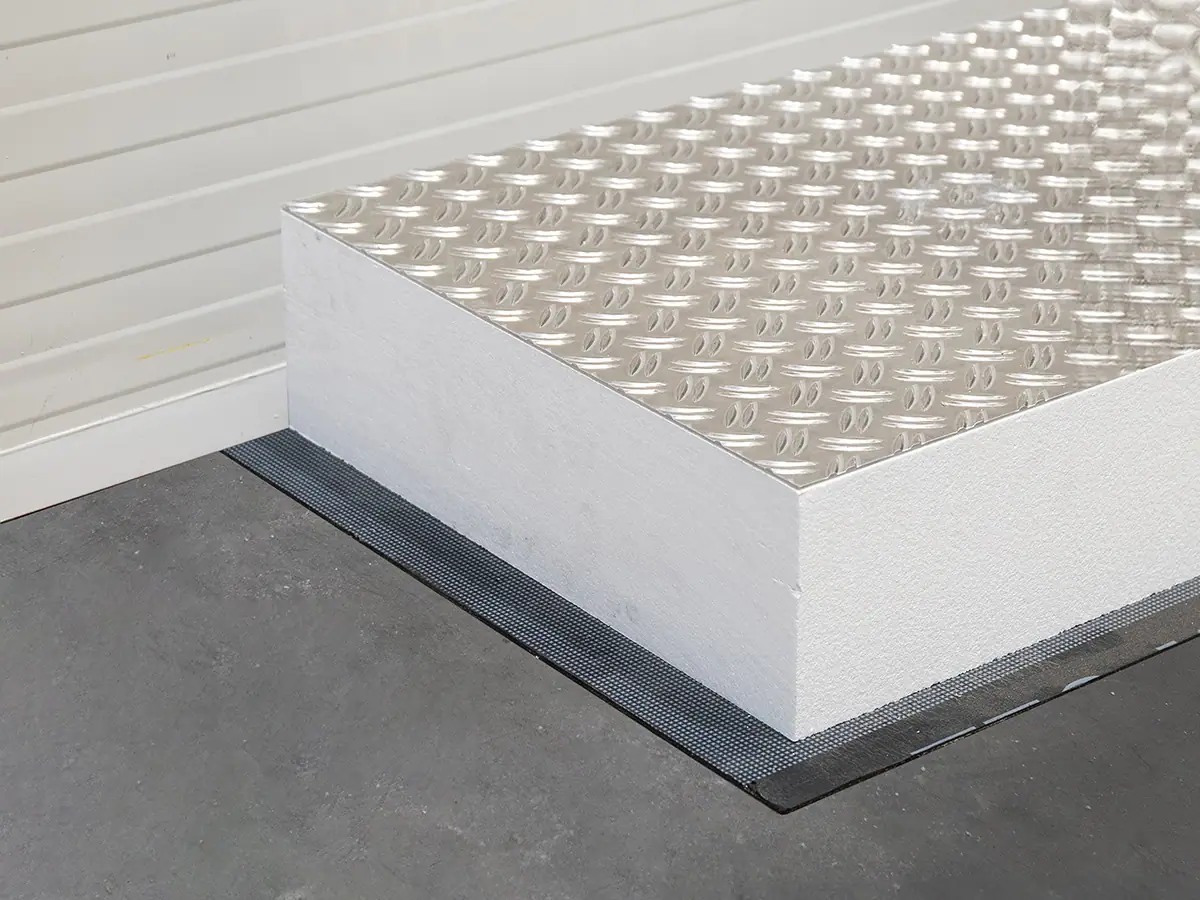

Permanently water-resistant & reliably stable

In showers, toilets and pantries, materials must be permanently water-resistant and reliably stable.

COMPACFOAM is the saltwater-resistant lightweight construction material that neither swells nor warps – even in direct contact with water.

The panels are absolutely insensitive to moisture. Temperature fluctuations or standing moisture do not affect the dimensional stability. In addition, the very good thermal insulation ensures a pleasant climate and reduces condensation.

The material offers unlimited durability even when in constant contact with water.

Request sample material nowTypical applications on board:

Another advantage: Due to the high strength of the core panels, thin cover layers are sufficient – this saves weight and costs. The panels are easy to screw together with standard wood screws and allow the use of conventional fittings without any additional reinforcements. Processing with standard woodworking tools enables precise adjustments, even for cut-outs for fittings or installations.

In comparison to wooden panels prevents COMPACFOAM reliable swelling and warping. Compared to PVC or PUR foam, it impresses with its absolute moisture resistance and freedom from warping. The result is durable, low-maintenance fittings below deck.

Highest loads & moisture resistant

In motor yachts, materials in technical rooms and wet rooms must be able to withstand the highest loads.

COMPACFOAM is the alternative to conventional lightweight building and construction materials – lighter than wood panels, more dimensionally stable than PVC or PUR foam and permanently moisture-resistant.

The panels remain undistorted even when exposed to temperature fluctuations, high humidity and vibrations.

Even in direct contact with water or fuel vapors, they do not swell and retain their shape permanently. This allows durable, low-maintenance constructions to be realized.

Request sample material nowTypical applications on board:

Another advantage: Due to the high strength of the core panels, thin cover layers are sufficient – this saves weight and costs. The panels are easy to screw together with standard wood screws and allow the use of common hardware systems without additional reinforcements. Processing is carried out precisely using CNC milling machines or standard wood tools.

In comparison COMPACFOAM is significantly lighter and moisture-resistant than conventional wood panels. Compared to PVC or PUR foam, it impresses with its freedom from warping and unlimited durability.

Speed, stability and fuel efficiency

In motor yachts, lightweight and stable superstructures determine speed, stability and fuel efficiency.

COMPACFOAM is the lightweight construction material for yacht building that combines high strength with low weight and thus reduces mass above the waterline.

The panels are dimensionally stable and retain their shape even when exposed to strong sunlight, temperature fluctuations and moisture. They are also resistant to salt water and reliably withstand fuel vapors – ideal for continuous maritime use.

Thanks to the very good thermal insulation, superstructures heat up less, which improves comfort on board.

Request sample material nowTypical applications on board:

Another advantage: The panels can be screwed together directly with standard wood screws, without any additional reinforcing elements.

In comparison COMPACFOAM significantly reduces the weight compared to conventional wooden panels. Compared to PVC or PUR foam, it impresses with its dimensional stability, absolute moisture resistance and unlimited durability. The result is structurally strong, durable superstructures that increase the performance of the motor yacht.

Greatest savings potential – removal weight

Furniture construction offers the greatest potential for reducing the weight of sailing yachts.

COMPACFOAM is the easy-to-process core material for lightweight sandwich structures in interior construction. It saves weight, remains dimensionally stable and is permanently resistant to salt water. You process COMPACFOAM with the same tools and methods as wooden panels.

Milling, sawing, screwing and gluing work without any problems. The material does not warp when exposed to moisture or temperature – for the longevity of the construction.

Typical applications on board:

In use, shipyards benefit from simple integration: The same fitting systems can be used as in conventional furniture construction. Reinforcements are not required.

Normal furniture edges can also be applied. Compared to plywood COMPACFOAM weight and moisture absorption. Compared to PVC or PUR foam, the main advantage is the absence of warping – the panels remain permanently straight.

Request sample material nowHigh dimensional stability & reduced weight

The material enables large-scale furniture components with high dimensional stability and reduced weight – without compromising on comfort or appearance.

COMPACFOAM is the lightweight construction material for fine furniture in yacht building, combining weight advantages with lasting dimensional stability.

Processing is the same as for wooden panels: milling, sawing, gluing and screwing are all possible with standard tools.

Even with changing temperatures and humidity, the components remain warp-free. This means that fronts, sideboards and built-in units retain their perfect appearance in the long term.

Typical applications on board:

Decorative surfaces and visible edges can be processed without any problems.

Compared to plywood, the construction weight is significantly lower: Compared to PVC or PUR foam COMPACFOAM due to absolute dimensional stability – the panels remain straight, even with large components.

Another advantage: The material is free from formaldehyde and other outgassing – a plus for healthy interiors.

Request sample material nowReduced weight & maximum dimensional stability

Lightweight, stable partition walls are crucial for a functional room layout on board.

COMPACFOAM is the core material for yacht construction that reduces weight while offering maximum dimensional stability.

The panels remain undistorted even with changing humidity or temperature. This eliminates the need for reworking due to deformation – a clear advantage in the interior fitting of sailing yachts, even with very large elements.

Its excellent insulating effect against heat and cold helps to prevent condensation in cabins and storage spaces.

The material is free of formaldehyde and other outgassing, which contributes to healthy interiors.

Typical applications on board:

Processing is carried out using standard wood tools, which makes installation easier. The panels are available in excess lengths and special widths according to customer requirements – ideal for impact-free constructions. The panel thickness is adjusted exactly to the required wall thickness.

Due to the high strength of the core panels, only very thin and light surfaces need to be applied.

This saves weight and costs.

In comparison to conventional wooden panels is COMPACFOAM significantly lighter and also moisture-resistant. PVC or PUR foam boards have a tendency to warp. COMPACFOAM remains straight and dimensionally stable.

Request sample material nowHigh load capacity – low weight

Dimensionally stable materials are crucial for switchgear, control stations and supply system cladding.

COMPACFOAM is the construction material for maritime use that combines high load-bearing capacity with low weight. The panels remain absolutely dimensionally stable even with changing temperatures, vibrations and moisture.

This ensures that sensitive technical areas function reliably. Thanks to the high strength, very thin and light cover layers can be applied – this saves weight and costs.

Typical applications on board:

A special advantage lies in its precise machinability: COMPACFOAM is ideal for use on CNC milling machines. Cut-outs for displays, ventilation slots, switches or cable ducts can be produced precisely and with repeat accuracy. The panels are also easy to screw together using standard wood screws – without any reinforcing elements.

In comparison to conventional wooden panels is COMPACFOAM significantly lighter and also resistant to moisture. PVC or PUR foam boards tend to to deformation, while COMPACFOAM remains straight and stable – even with temperature differences.

Request sample material nowPermanently water-resistant & reliably stable

In showers, toilets and pantries, materials must be permanently water-resistant and reliably stable.

COMPACFOAM is the saltwater-resistant lightweight construction material that neither swells nor warps – even in direct contact with water.

The panels are absolutely insensitive to moisture. Temperature fluctuations or standing moisture do not affect the dimensional stability. In addition, the very good thermal insulation ensures a pleasant climate and reduces condensation.

The material offers unlimited durability even when in constant contact with water.

Typical applications on board:

Another advantage: Due to the high strength of the core panels, thin cover layers are sufficient – this saves weight and costs. The panels are easy to screw together with standard wood screws and allow the use of conventional fittings without any additional reinforcements. Processing with standard woodworking tools enables precise adjustments, even for cut-outs for fittings or installations.

In comparison to wooden panels prevents COMPACFOAM reliable swelling and warping. Compared to PVC or PUR foam, it impresses with its absolute moisture resistance and freedom from warping. The result is durable, low-maintenance fittings below deck.

Request sample material nowHighest loads & moisture resistant

In motor yachts, materials in technical rooms and wet rooms must be able to withstand the highest loads.

COMPACFOAM is the alternative to conventional lightweight building and construction materials – lighter than wood panels, more dimensionally stable than PVC or PUR foam and permanently moisture-resistant.

The panels remain undistorted even when exposed to temperature fluctuations, high humidity and vibrations.

Even in direct contact with water or fuel vapors, they do not swell and retain their shape permanently. This allows durable, low-maintenance constructions to be realized.

Typical applications on board:

Another advantage: Due to the high strength of the core panels, thin cover layers are sufficient – this saves weight and costs. The panels are easy to screw together with standard wood screws and allow the use of common hardware systems without additional reinforcements. Processing is carried out precisely using CNC milling machines or standard wood tools.

In comparison COMPACFOAM is significantly lighter and moisture-resistant than conventional wood panels. Compared to PVC or PUR foam, it impresses with its freedom from warping and unlimited durability.

Request sample material nowSpeed, stability and fuel efficiency

In motor yachts, lightweight and stable superstructures determine speed, stability and fuel efficiency.

COMPACFOAM is the lightweight construction material for yacht building that combines high strength with low weight and thus reduces mass above the waterline.

The panels are dimensionally stable and retain their shape even when exposed to strong sunlight, temperature fluctuations and moisture. They are also resistant to salt water and reliably withstand fuel vapors – ideal for continuous maritime use.

Thanks to the very good thermal insulation, superstructures heat up less, which improves comfort on board.

Typical applications on board:

Another advantage: The panels can be screwed together directly with standard wood screws, without any additional reinforcing elements.

In comparison COMPACFOAM significantly reduces the weight compared to conventional wooden panels. Compared to PVC or PUR foam, it impresses with its dimensional stability, absolute moisture resistance and unlimited durability. The result is structurally strong, durable superstructures that increase the performance of the motor yacht.

Request sample material nowKundenstimmen

“The material is incredibly light, which helps us to maximize the payload without compromising on stability.”

Markus L.

Production manager

“Always dimensionally stable even at extreme temperatures – a real improvement.”

Simone B.

Managing Director

“The material can be processed like wood, so we didn’t need any expensive machines or changes in production.”

Stefan H.

Design engineer

Why COMPACFOAM?

Simple and secure screw connection

COMPACFOAM can be easily screwed together with standard wood screws, ensuring a stable and durable connection. With pull-out strengths comparable to wood-based materials, but at only half the weight, the material is particularly suitable for inserts and fastenings in motor and sailing yachts.

Request a sample

Significant weight saving

One of the most outstanding features of COMPACFOAM is its low weight. Compared to traditional materials such as plywood or MDF, the overall weight of the yacht is significantly reduced. This enables better fuel efficiency and performance.

Request a sample

Unsurpassed dimensional stability

COMPACFOAM is extremely dimensionally stable. There are no changes in thickness or deflection over the entire service life. The material does not react to changes in humidity or extreme temperatures and always retains its original shape. This ensures consistent performance and prevents deformation over time.

Request a sample

Insensitive to the effects of moisture

In contrast to many other materials, which change their structure or even become irreparably damaged when exposed to moisture, the COMPACFOAM stable even when constantly exposed to moisture. This moisture resistance makes it the ideal choice for use in wet rooms.

Request a sample

Perfect as a construction core

COMPACFOAM is the easy-to-process core material for lightweight sandwich structures in interior construction. It saves weight, remains dimensionally stable and is permanently resistant to salt water. You process COMPACFOAM with the same tools and methods as wooden panels.

Request a sample

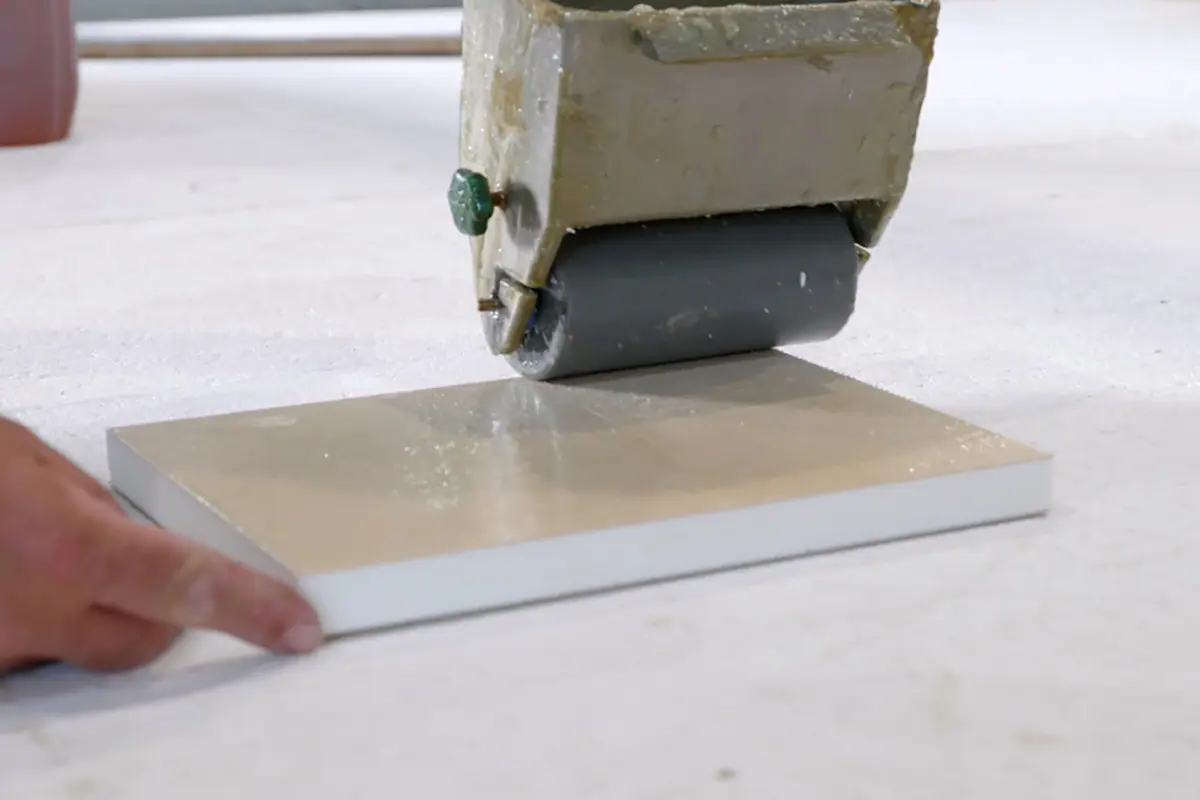

Simple integration into existing production processes

COMPACFOAM can be integrated into existing production processes without additional conversion. It can be processed with the same machines as wood, including cutting, milling and gluing. Screwing directly into the material also works in the same way as with wood, which enables quick adaptation to your production processes.

Request a sample

Healthy indoor climate on board – formaldehyde-free for crew and guests

Formaldehyde is considered carcinogenic and causes irritation of the respiratory tract, skin and mucous membranes as well as headaches. In the enclosed space of a yacht, conventional materials can pollute the indoor air for years. Modern formaldehyde-free COMPACFOAM panels, on the other hand, create a healthy indoor climate without harmful outgassing. Particularly in cabins where people spend long periods of time, pollutant-free air is crucial for well-being and health.

Request a sample

Decorative and easy to work with

COMPACFOAM make it easy to apply normal furniture edges for high-quality surface design. Compared to plywood, the processing effort is considerably reduced as no complex edge sealing is required.

Decorative surfaces and visible edges can be processed without complications and create a sophisticated look. In yacht interiors, high-quality surfaces and clean edges are crucial for the overall impression of the cabins.

Request a sample

COMPACFOAM can be easily screwed together with standard wood screws, ensuring a stable and durable connection. With pull-out strengths comparable to wood-based materials, but at only half the weight, the material is particularly suitable for inserts and fastenings in motor and sailing yachts.

Request a sample

One of the most outstanding features of COMPACFOAM is its low weight. Compared to traditional materials such as plywood or MDF, the overall weight of the yacht is significantly reduced. This enables better fuel efficiency and performance.

Request a sample

COMPACFOAM is extremely dimensionally stable. There are no changes in thickness or deflection over the entire service life. The material does not react to changes in humidity or extreme temperatures and always retains its original shape. This ensures consistent performance and prevents deformation over time.

Request a sample

In contrast to many other materials, which change their structure or even become irreparably damaged when exposed to moisture, the COMPACFOAM stable even when constantly exposed to moisture. This moisture resistance makes it the ideal choice for use in wet rooms.

Request a sample

COMPACFOAM is the easy-to-process core material for lightweight sandwich structures in interior construction. It saves weight, remains dimensionally stable and is permanently resistant to salt water. You process COMPACFOAM with the same tools and methods as wooden panels.

Request a sample

COMPACFOAM can be integrated into existing production processes without additional conversion. It can be processed with the same machines as wood, including cutting, milling and gluing. Screwing directly into the material also works in the same way as with wood, which enables quick adaptation to your production processes.

Sample requests

Formaldehyde is considered carcinogenic and causes irritation of the respiratory tract, skin and mucous membranes as well as headaches. In the enclosed space of a yacht, conventional materials can pollute the indoor air for years. Modern formaldehyde-free COMPACFOAM panels, on the other hand, create a healthy indoor climate without harmful outgassing. Particularly in cabins where people spend long periods of time, pollutant-free air is crucial for well-being and health.

Request a sample

COMPACFOAM make it easy to apply normal furniture edges for high-quality surface design. Compared to plywood, the processing effort is considerably reduced as no complex edge sealing is required.

Decorative surfaces and visible edges can be processed without complications and create a sophisticated look. In yacht interiors, high-quality surfaces and clean edges are crucial for the overall impression of the cabins.

Request a sample

Videos

COMPACFOAM – structural lightweight panels. Dimensional stability

Structural lightweight sandwich panels. Milling of hardware connection elements

Lightweight structural panels Lamello fasteners

Tested at

FAQ – Frequently asked questions about COMPACFOAM in yacht building

Yes, the freedom from warping is measurable. In contrast to PVC or PUR foam boards, which tend to warp when exposed to temperature fluctuations and moisture, COMPACFOAM remains permanently straight, even with large-surface components. This property has been confirmed in years of maritime use.

Permanently resistant without swelling. Unlike plywood or balsa wood, COMPACFOAM does not absorb salt water and does not rot. Dimensional stability is maintained even when in direct contact with water in wet rooms.

Comprehensive technical documentation available. COMPACFOAM has building law certificates and test certificates for maritime use. The complete documentation is provided with the delivery.

Yes, with standard tools. Sawing, routing, drilling and sanding all work with standard woodworking tools. CNC processing is also possible without any problems. There are no additional tool costs.

No, standard fastenings are sufficient. COMPACFOAM can be screwed directly with standard wood screws – without reinforcing elements. Standard PUR or epoxy adhesives work for gluing.

Yes, customized solutions possible. COMPACFOAM can be supplied in excess lengths and special widths according to customer requirements – ideal for impact-free constructions.

The overall calculation shows clear advantages. The additional price is amortized through weight savings, reduced reworking and longer durability. Added to this are savings in transportation and handling due to the lower weight.

Depending on the application, 30-50% less weight. Significant weight reductions are possible for furniture and partition walls. This improves sailing characteristics and reduces fuel consumption on motor yachts.

Yes, without restrictions. Pot hinges, pull-outs and other fitting systems can be installed as usual. The high strength of the core material makes additional reinforcements superfluous.

Simple repair using standard methods. Minor damage can be filled and repaired in the same way as wood. In the case of major damage, sections can be replaced and seamlessly inserted.

Yes, formaldehyde-free and without outgassing. COMPACFOAM contributes to healthy interiors – an important aspect in the confined space situation on board.

Unlimited durability under normal conditions. The material shows no signs of ageing due to salt water or temperature fluctuations. Reference projects prove the long-term stability.

Yes, sample material is also available. We are happy to provide sample panels for testing and sampling. This allows you to check the processing properties in advance.

Comprehensive application technology included. Our team provides support with material selection, dimensioning and processing technology. Our advice is geared towards the practical requirements of yacht building.

Short delivery times even for special dimensions. Standard dimensions are available from stock. Custom-made products are scheduled on a project-specific basis.

Flexible adaptation to structural requirements. The panel thickness is adapted precisely to the required wall thickness and load. Due to the high strength, thinner structures are often sufficient than with other materials.