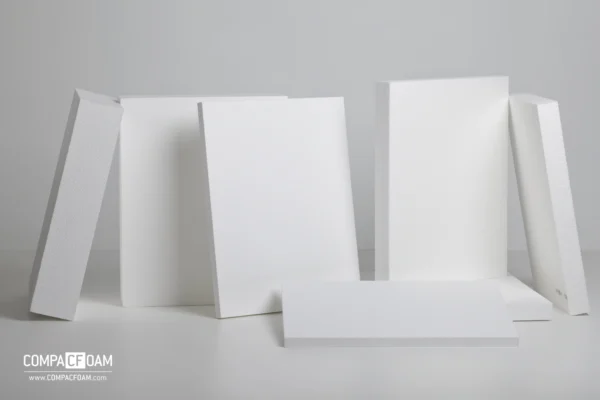

Plate for self-cutting

Standard dimensions: 2350x780mm Please select the desired thickness or select “individual” to enter your individual dimensions.

The CF material classes differ primarily in terms of compressive strength, thermal conductivity and screw extraction. To determine the optimum material class for your application, please use the table in the Data tab. We would also be happy to advise you personally.

COMPACFOAM can be used wherever a moisture-resistant construction material is required but wood-based materials are not a solution.

We produce without propellants and adhesives, without questionable additives or fossil fuels. This means there are no harmful emissions. COMPACFOAM is insensitive to climatic influences, but still diffusion-open and breathable.

Advantages:

- High strength

- Excellent thermal insulation

- Moisture resistant

- climate resistant

- Easy to process

- 100% single-variety

- Sustainable

- Pollutant-free – without propellants, adhesives or fossil fuels

COMPACFOAM is perfect for the following applications:

- Pre-wall installations

- Window sill connection insulation profiles

- Substructure insulation profiles

- Frame extensions

- Panel edge reinforcement

- Vehicle construction

| Sintered highly compressed EPS | CF100 | CF125 | CF150 | CF200 | CF300 | CF400 | CF200eco | Standard | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gesintertes hochverdichtetes EPS | Standard | |||||||||||||

| Compressive strength (N/mm²) | ||||||||||||||

| for 10% compression | 1,13 | 1,64 | 1,95 | 3,53 | 5,85 | 11,03 | 2,62 | EN 826 | ||||||

| for 2% compression | 0,73 | 0,81 | 0,98 | 1,93 | 3,01 | 4,31 | 1,54 | EN 826 | ||||||

| Characteristic compressive strength (N/mm²) | 1,02 | 1,48 | 1,55 | 3,19 | 5,19 | 9,97 | 2,37 | EN 14358 | ||||||

| Rated value of compressive strength (N/mm²) | 0,71 | 1,02 | 1,07 | 2,21 | 3,59 | 6,90 | 1,42 | |||||||

| Safety factors | ym=1,3/k mod=0,9 | ym=1,5/k mod=0,9 | ||||||||||||

| Calculation value for Serviceability (N/mm²) | 0,62 | 0,69 | 0,83 | 1,64 | 2,56 | 3,66 | 1,23 | |||||||

| E-modulus (N/mm²) | 28,7 | 38,4 | 45,5 | 99,4 | 168,7 | 269,8 | 73 | EN 826 | ||||||

| Screw extraction | ||||||||||||||

| Screw extraction* ⌀ 7.5mm (N) | 837 | 919 | 1.179 | 1.875 | 2.677 | 4.047 | 1.380 | i.a. EN 14358 | ||||||

| Screw cross tension* ⌀ 7.5mm (N) | 296 | 394 | 493 | 542 | 1.012 | 1.333 | 954 | i.a. EN 14358 | ||||||

| Screw extraction* ⌀ 4.5mm (N) | 505 | 565 | 747 | 979 | 1.729 | 2.829 | 701 | i.a. EN 14358 | ||||||

| Cross bolt tension* ⌀ 4.5mm (N) | 103 | 112 | 150 | 214 | 319 | 500 | 320 | i.a. EN 14358 | ||||||

| Thermal conductivity | ||||||||||||||

| Rated value (W/mK) | 0,0387 | 0,0377 | 0,0423 | 0,0459 | 0,0531 | 0,0650 | 0,045 | EN 12667 | ||||||

| Water vapor diffusion resistance coefficient | ~25 | EN 12086-1 | ||||||||||||

| Building material behavior in case of fire | E (B1) schwer entflammbar | EN 13501-1, DIN 4102-1 | ||||||||||||

| Max. Water absorption capacity 28 days | ~5% | EN 12087 | ||||||||||||

* with 40 mm anchoring length

** with 1.5 mm max. head deformation, 40 mm anchoring length, 30 mm edge distance