COMPACFOAM – the perfect component in the refrigeration sector

Thermally insulating, highly pressure-resistant, climate-stable & moisture-resistant

Core elements with high load-bearing capacity and excellent insulation values

Discover now

Optimized designs in all areas of refrigeration technology

The quest to optimize energy consumption is forcing us to overcome old design patterns. Cold store and refrigeration unit designs are being rethought. COMPACFOAM is a crucial component on the way there. COMPACFOAM combines excellent thermal insulation values with a very high compressive load and good screwability. Climate changes do not lead to any changes in dimensions. Even moisture does not affect the material, so that it has complete long-term stability.

Applications in the field of refrigeration technology

Components for cold rooms and cold stores

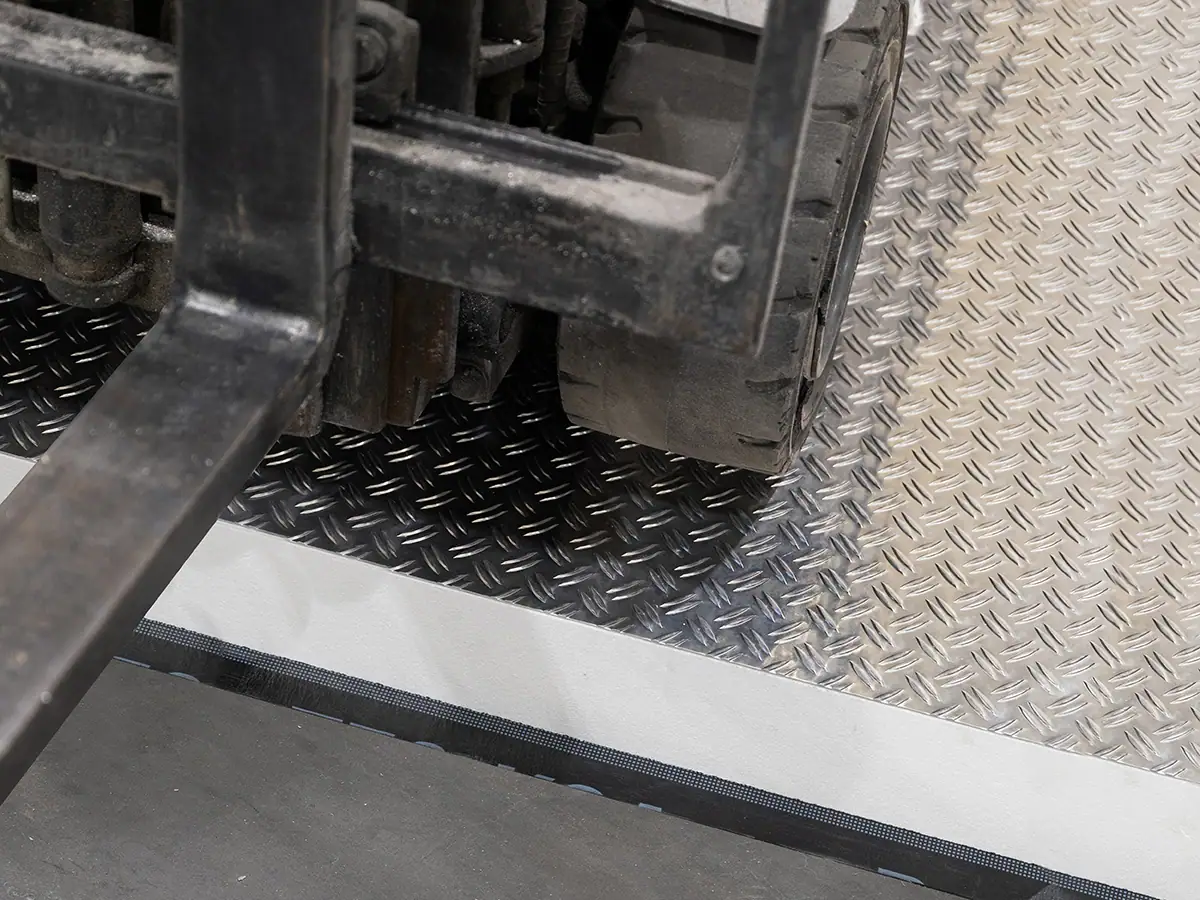

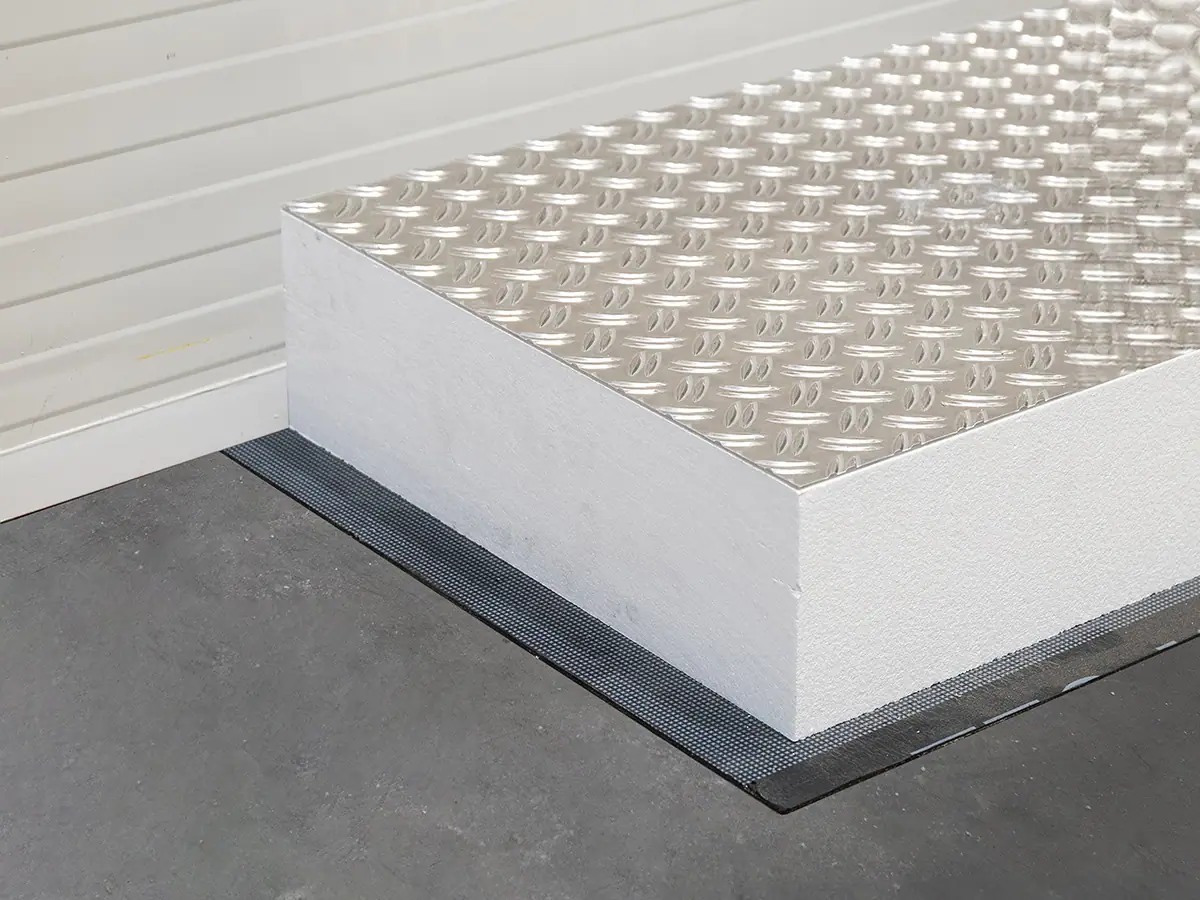

Thanks to its properties, COMPACFOAM is predestined for use as a structural insulation material in cold rooms. While the high compressive strength in combination with the excellent insulating properties play a key role in the floor area – COMPACFOAM is used both as a load-bearing floor layer and as an insulating layer – COMPACFOAM is used as a core element in the walls of cold storage cells due to the combination of screwability and thermal insulation.

By simply avoiding thermal bridges, cost-effectiveness can be significantly increased. Expensive special solutions can be avoided.

Inserts for cooling elements

With our high-precision CNC systems, we can COMPACFOAM in any desired shape. We can produce both series and individual pieces economically. COMPACFOAM is used as a structural insulating element that is screwable, climate-stable and moisture-resistant. It therefore has all the properties to be used where other materials fail.

Components for cold rooms and cold stores

Thanks to its properties, COMPACFOAM is predestined for use as a structural insulation material in cold rooms. While the high compressive strength in combination with the excellent insulating properties play a key role in the floor area – COMPACFOAM is used both as a load-bearing floor layer and as an insulating layer – COMPACFOAM is used as a core element in the walls of cold storage cells due to the combination of screwability and thermal insulation.

By simply avoiding thermal bridges, cost-effectiveness can be significantly increased. Expensive special solutions can be avoided.

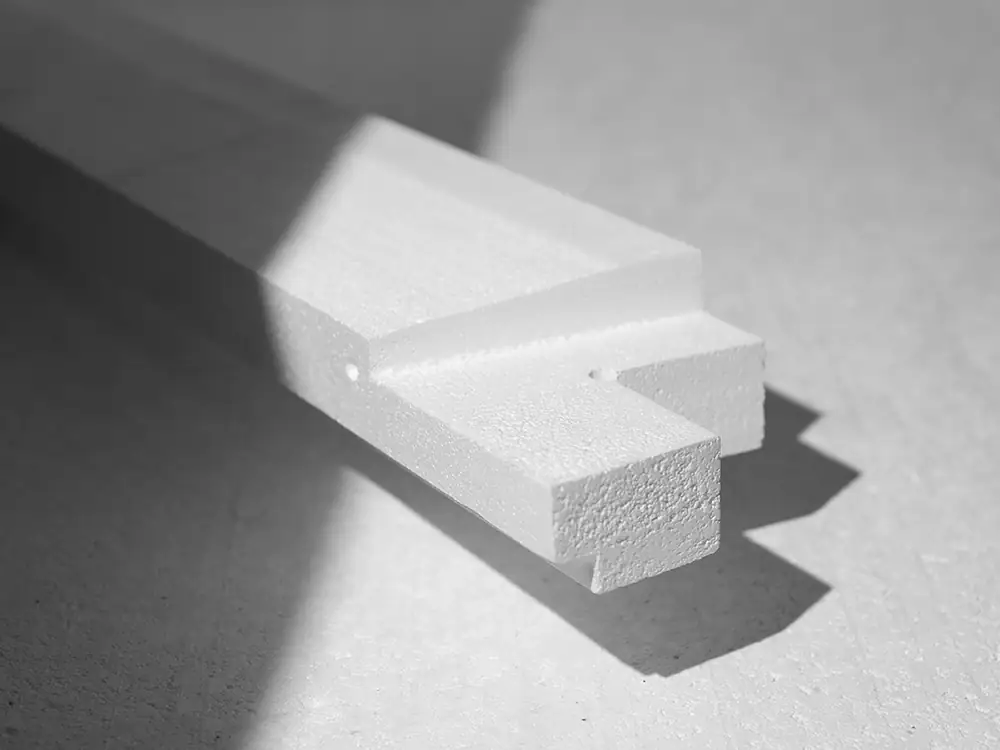

Inserts for cooling elements

With our high-precision CNC systems, we can COMPACFOAM in any desired shape. We can produce both series and individual pieces economically. COMPACFOAM is used as a structural insulating element that is screwable, climate-stable and moisture-resistant. It therefore has all the properties to be used where other materials fail.

Compressive strength

Climate stable

Recyclable

Long-term stability

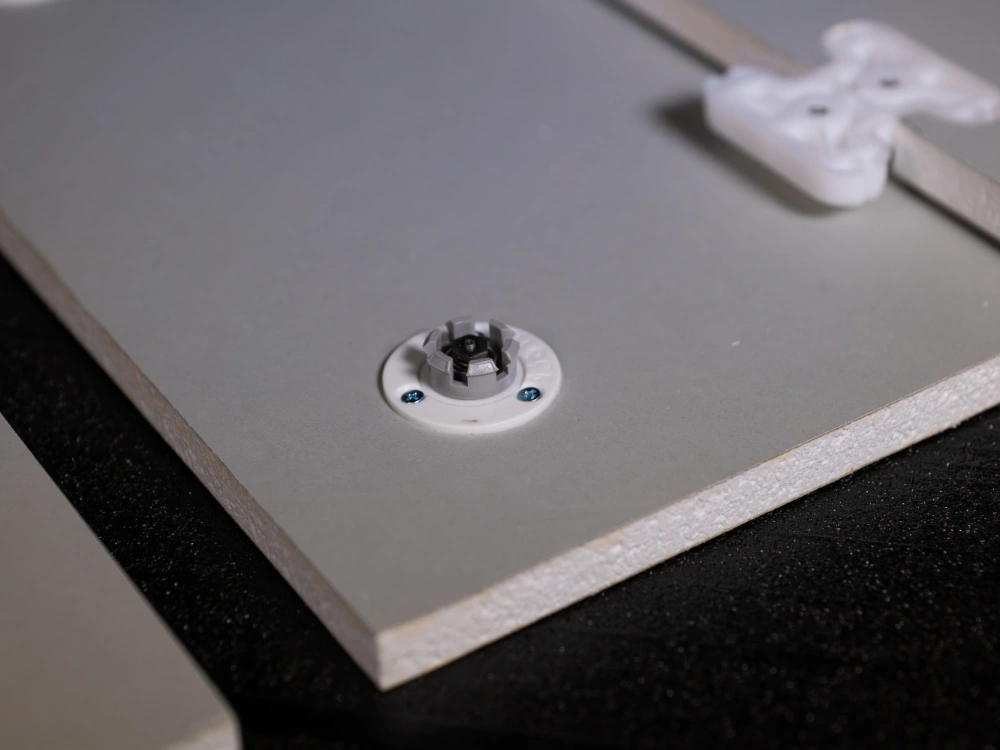

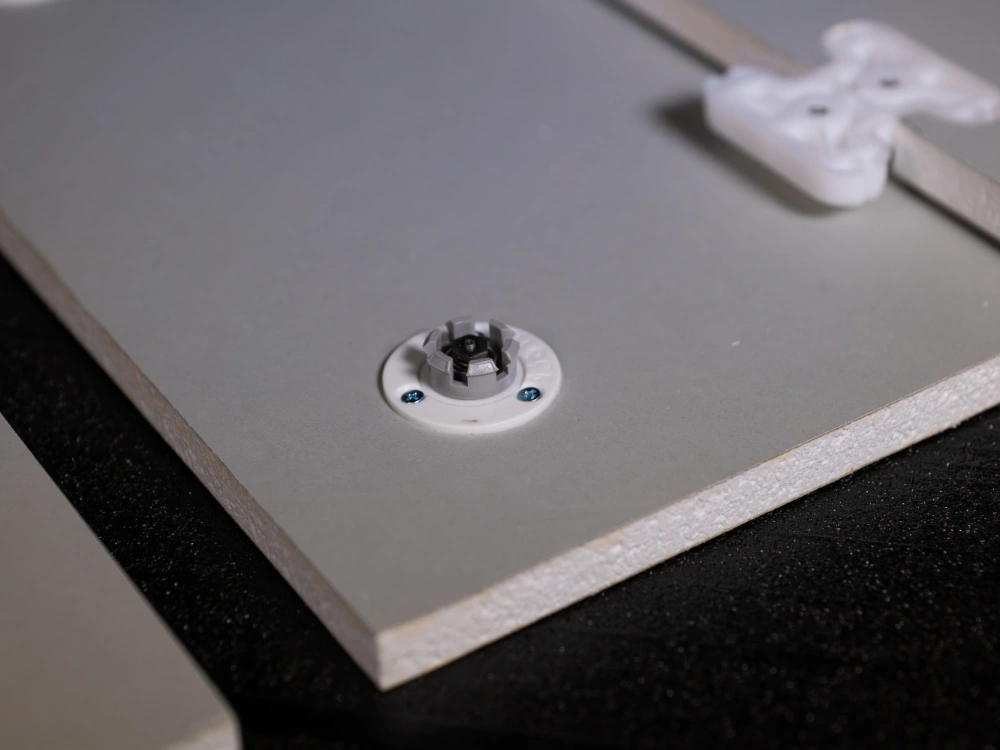

Screw-proof

Waterproof

Thermally insulating

Frost resistant

Cutting with a saw

Delivery forms

Perfect for increasing your flexibility.

Perfect as a precisely fitting component.

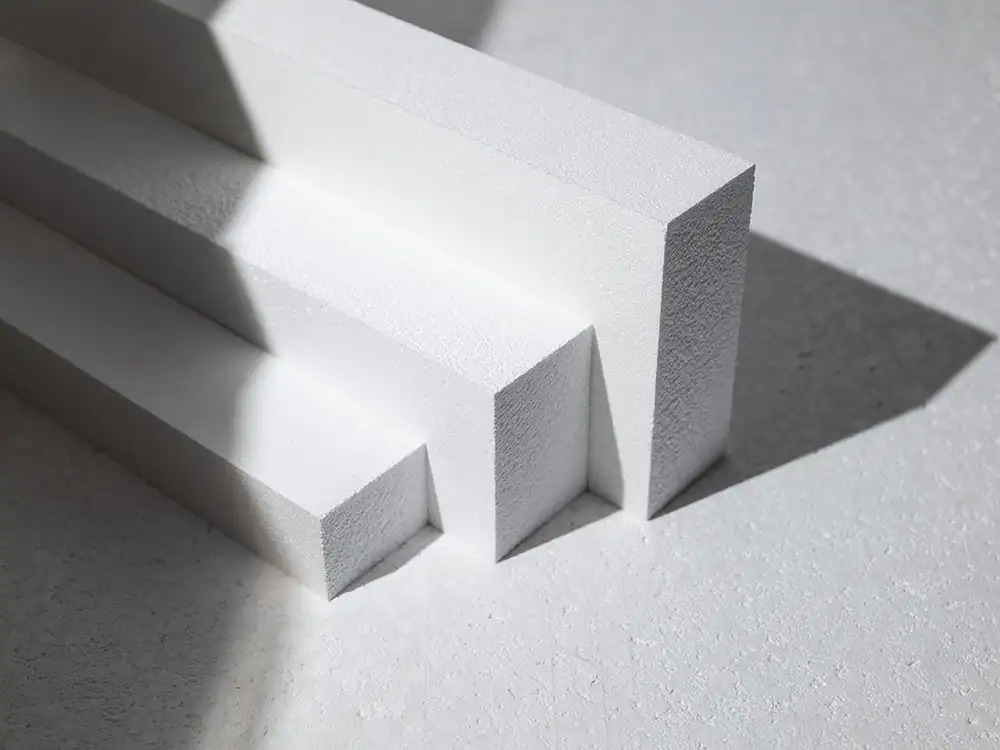

Perfect as a substructure for threshold solutions in cold rooms.

(Milled) bars

Screws, adhesive, brackets for mounting COMPACFOAM elements.

Tested at

Sustainability

With the help of a newly developed process, particle technology, we can reduce the waste of COMPACFOAM recycle to 100 %. CFeco, the result of this process, offers the same good properties as COMPACFOAMhigh strength with excellent thermal insulation.

This increases the recycling rate and improves the eco-balance of your project and company. Because environmental protection means keeping things in circulation instead of disposing of them at great expense.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFAQ

The choice of the right material class depends primarily on the required screw pull-out strength and compressive strength. Larger screws generally allow the use of a lighter material class. Typical material classes are:

Window installation: CFeco and CF125

Sandwich cores for vehicle and furniture construction: CF200

Thermal break for steel structures: CF200, CF300, CF400

We are happy to support you in dimensioning and selecting the right material class to ensure that the solution is optimally tailored to your requirements. Do not hesitate to contact us if you have any questions or uncertainties!

Yes, COMPACFOAM is available in individual dimensions. The only limitation is usually the practical transport dimensions. Profiling and milling according to customer specifications are also possible.

Standard panels are available in all required thicknesses and strength classes. Cutting to size is easy with normal woodworking machines. Please use the saw blade recommended by us with a large tooth spacing. No substances harmful to health or the environment are produced during cutting.

The minimum dimensions are 6 mm thickness, 10 mm widthand the maximum dimensions are 500 mm thick, 1300 mm wide and 6000 mm long. Standard panels are also available for self-cutting.

All screws with a wood thread are suitable for installation. If there is sufficient space, a window frame screw with a diameter of 7.5 mm is recommended. Wood screws with a diameter of 4 mm are ideal for smaller components. Pre-drilling is not necessary and screws can also be used close to the edge without any problems.

COMPACFOAM has an unlimited shelf life under normal conditions. Moisture, water and frost do not affect the technical properties. UV radiation only has a minor superficial effect, meaning that even prolonged outdoor storage during the construction phase is unproblematic.