Metal construction

Panel edge reinforcement

The dimensionally stable and pressure-resistant panel edge reinforcement from COMPACFOAM is the ideal insulation material for high stresses in the edge area of sandwich elements. The edge reinforcements guarantee permanent and consistent clamping without deformation.

Sandwich panels in highly thermally insulated window and façade constructions, as well as frame constructions with glazing beads, require appropriate thermal insulation values and high compressive strength at the insulation level.

The bars are individually cut to size for you based on the panel thickness and edge width specifications. The thickness tolerance is +/- 0.3 mm.

The components can be easily cut to the required panel thickness from standard panels using circular saws or we can manufacture rods to your exact specifications.

The material guarantees freeze-thaw stability and freedom from deformation in this critical area over the entire service life. This is the basis for a durable and tight connection. The “warm edge” also enables optimum U-values for sandwich elements. Even under extreme humidity and temperature conditions, COMPACFOAM is extremely dimensionally stable.

Details

In addition to ready-made bars in width and height, we also supply whole panels in the desired thickness. These offer you even greater flexibility to cut the bars to size yourself in your own workshop.

Apart from the standard length (2350mm), you can order any other length up to 6m from us.

COMPACFOAM can be easily cut to size using commercially available saws such as circular saws, pressure beam saws or hand-held circular saws. It is important to use saw blades with a wide tooth spacing and free chip space.

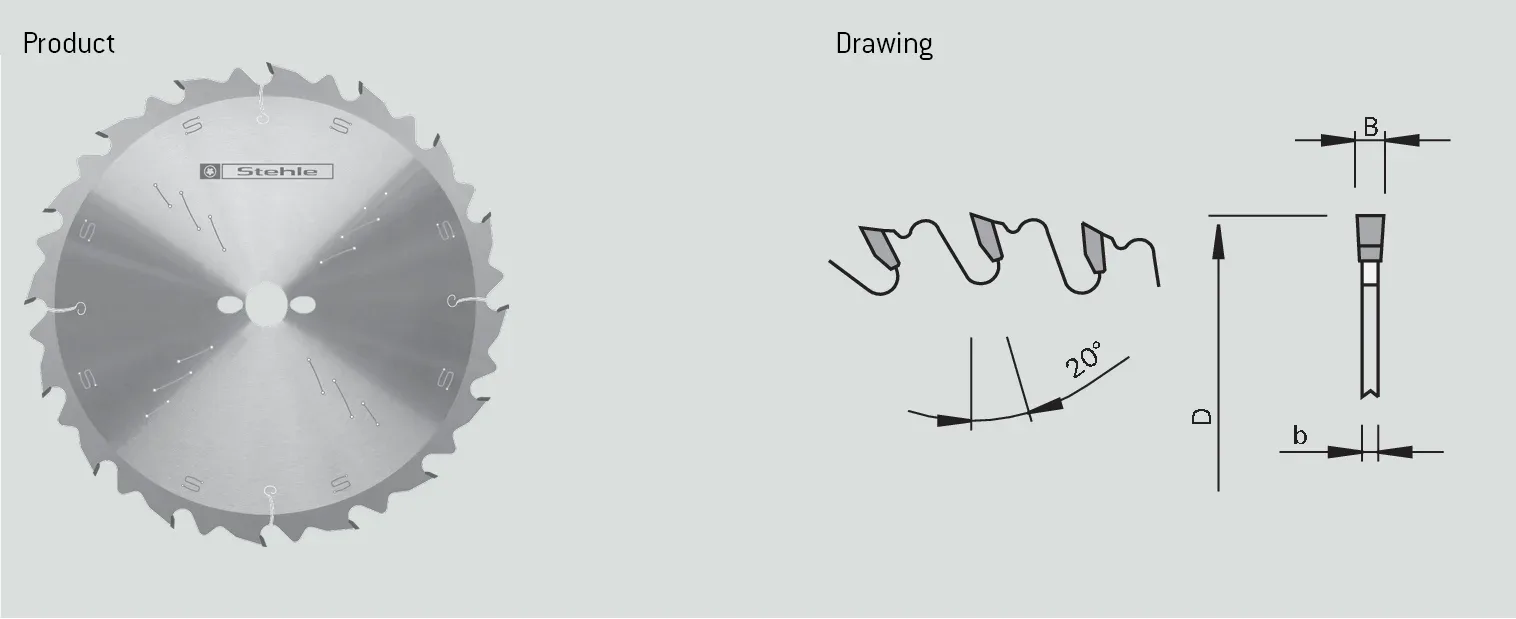

For the cutting of COMPACFOAM we recommend saw blades with flat teeth and chip thickness limiter and very large tooth pitch. Optimum cutting results are achieved at 2000 rpm.

Saw blade recommendation

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWith its optimum thermal conductivity of 0.0387 W/mK, CF100 is ideal for panel edge reinforcement.

Bonding the Compacfoam edge reinforcements

The Compacfoam edge reinforcements are simply bonded using MS polymer assembly adhesives or PU adhesives. Suitable adhesives can be supplied by us on request.

here you will find suitable adhesivesWith the help of a newly developed process, particle technology, we can recycle 100% of the offcuts of COMPACFOAM. CFeco200, the result of this process, offers the same good properties as COMPACFOAM: high strength with excellent thermal insulation.

This increases the proportion of recycled materials in construction and improves the eco-balance of your project and company. Because environmental protection means keeping things in circulation instead of disposing of them at great expense.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information