COMPACFOAM – the perfect solution for façade construction

Thermally insulating, highly resilient, moisture-resistant and permanently dimensionally stable

Safe and economical installation of thermal bridge-free façade elements

Discover now

Thermal break for façade systems/WDVS

The focus is on thermal bridge-free implementation, both for curtain wall façades and for installation in external thermal insulation composite systems. Thanks to its excellent insulating properties and exceptionally high compressive strength, COMPACFOAM is ideal for these tasks. Even heavy loads can be easily attached to the ETICS with COMPACFOAM. Prefabricated separating bearings are used for façade installation.

Applications

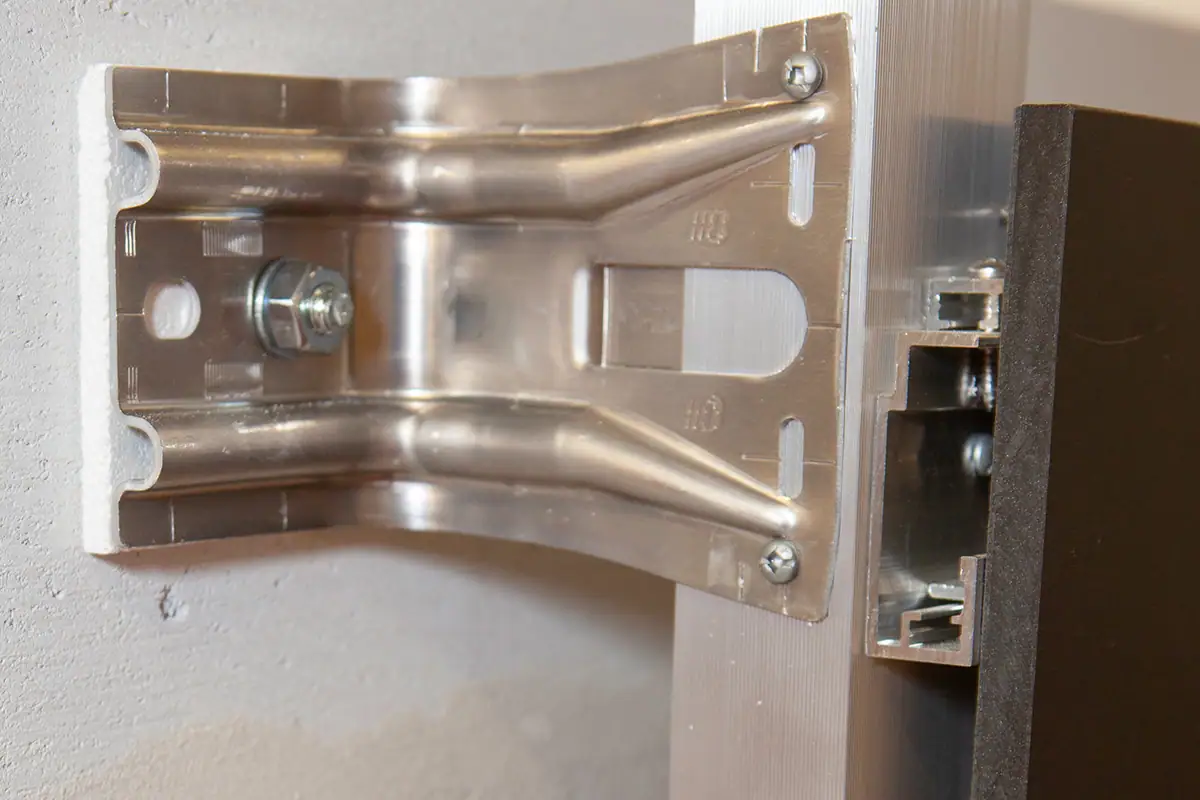

Thermal break façade systems

Compacfoam is used for the thermally separated installation of façade systems. Separation layers of 1-2 cm under brackets and mounting points significantly reduce heat loss through local thermal bridges. The bearings can be supplied pre-assembled or cut from panels on site. Adaptations with milling to system components are possible without any problems.

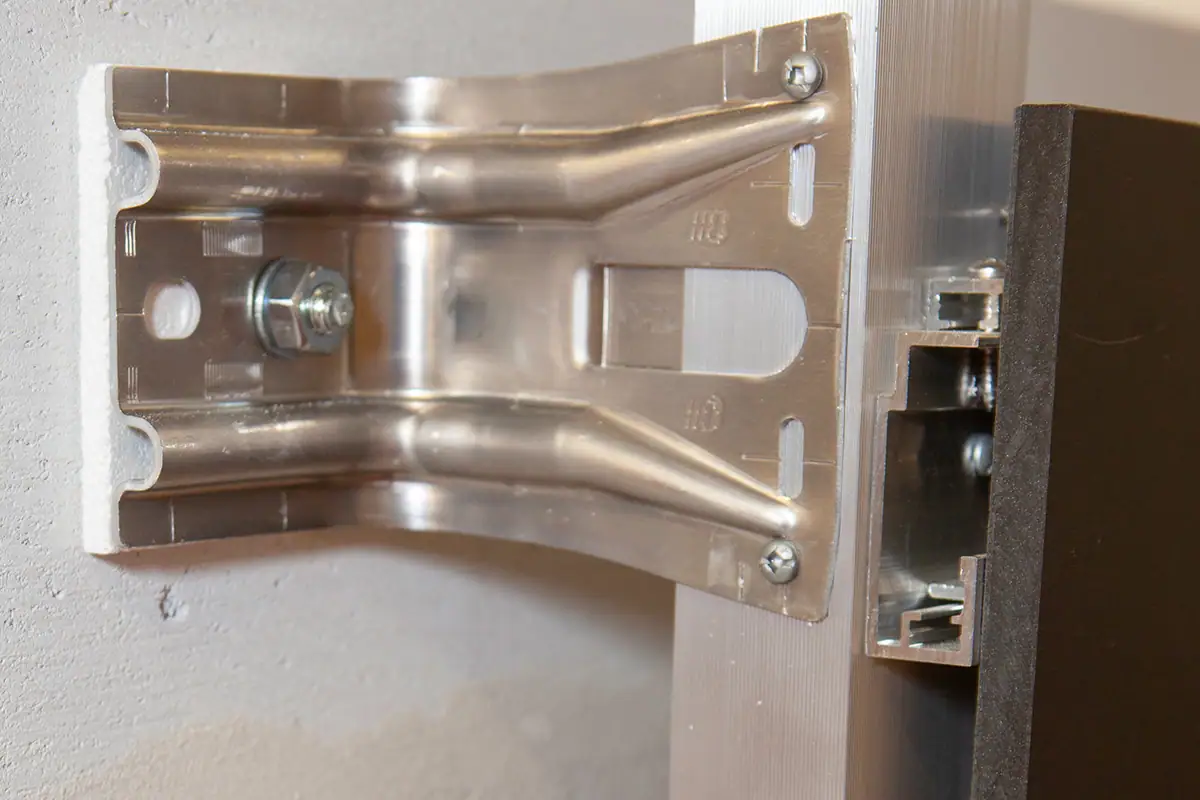

Mounting bracket for hinged and sliding shutters in ETICS

Hinged shutters in particular exert incredible forces on the substructure. Elements must be permanently stable, pressure-resistant and, above all, well insulating. Even with very high façade insulation thicknesses, the COMPACFOAM mounting block meets these requirements. The mounting block is attached directly to the wall with adhesive as an element of the full thermal insulation. To attach the awning bracket, bolt anchors or a threaded rod are anchored through the mounting block into the load-bearing wall.

Mounting elements for awnings in ETICS

Increasing façade insulation thicknesses require new solutions for fixing awnings, as previous fixing systems usually only work up to an ETICS thickness of 160 mm. Installation should also be simple and free of thermal bridges. COMPACFOAM meets these requirements. You can COMPACFOAM in any desired format – ready-made as a mounting block or to cut to length yourself as a mounting rod. On request, we can take the hole pattern of the bracket into account.

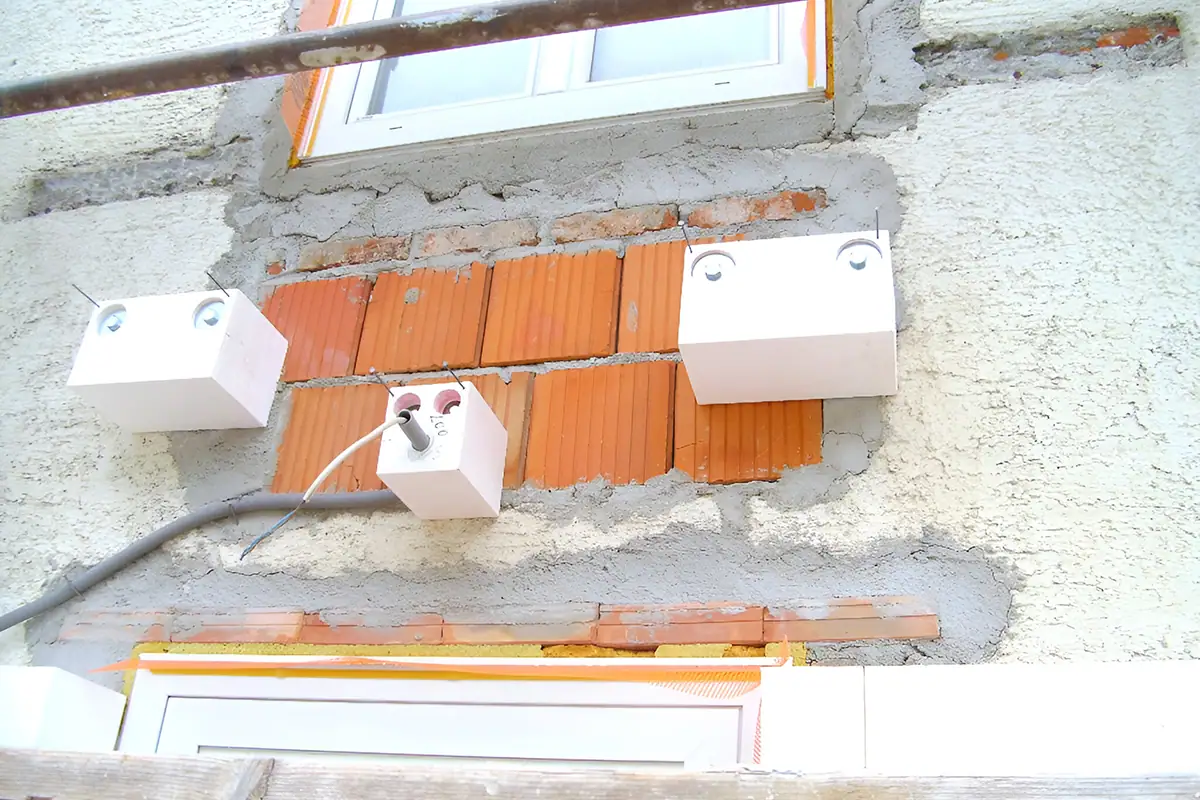

Mounting elements for medium-heavy loads in ETICS

The installation of low-load components on the external thermal insulation composite system requires new fastening solutions with increasing insulation thicknesses. The COMPACFOAM-Mounting components are supplied either as rectangular blocks, rectangular bars or mounting elements adapted to the required geometry of the component. Bars can simply be cut to the required insulation thickness on site. Tensile forces can be transferred to the construction level (masonry, reinforced concrete, etc.) using steel anchors. For medium loads, installation can be carried out using standard wood screws without pre-drilling directly in COMPACFOAM take place.

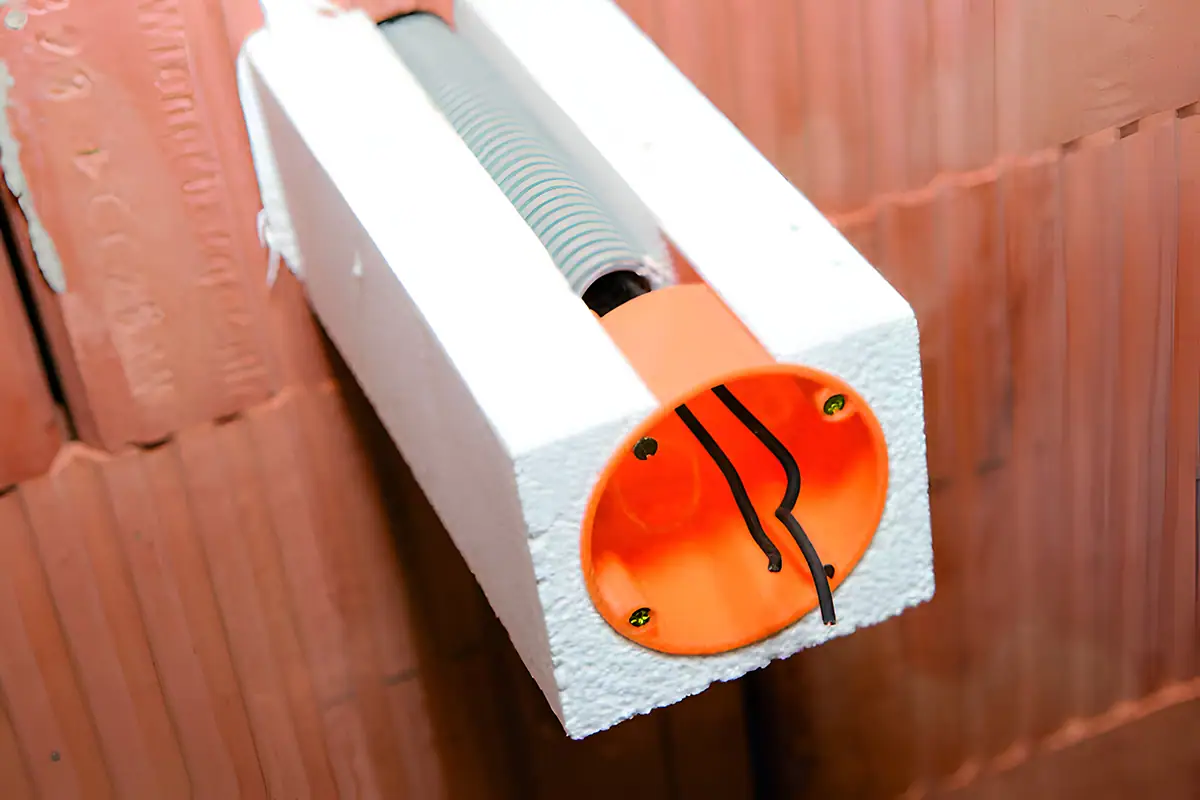

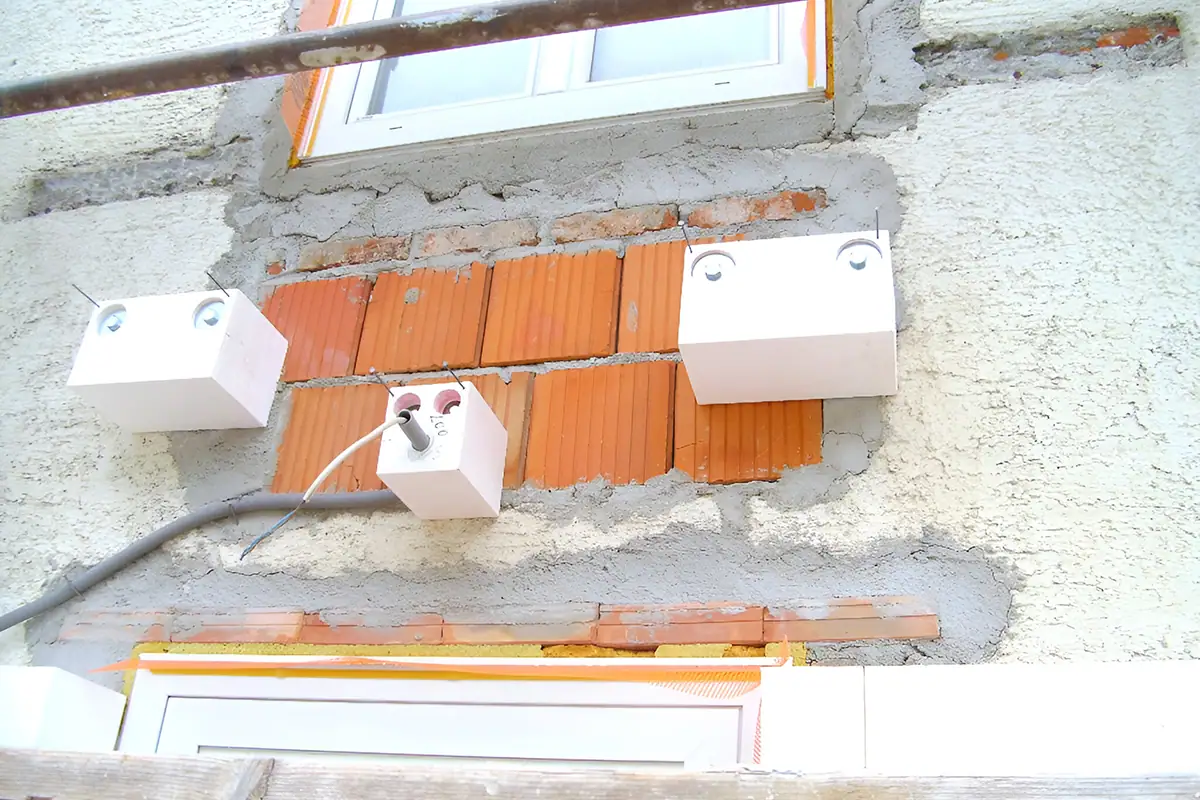

Mounting elements for electrical sockets in ETICS

External sockets that are fixed in the ETICS are subject to particular stress: repeated tensile forces when disconnecting power cables usually cause the sockets to tear out after some time. The COMPACFOAM-The CF electrical mounting element (round or square) is firmly anchored to the masonry, while the socket itself is screwed into the CF element. This creates COMPACFOAM the perfect combination: fixed anchoring and yet a continuous thermal insulation composite system.

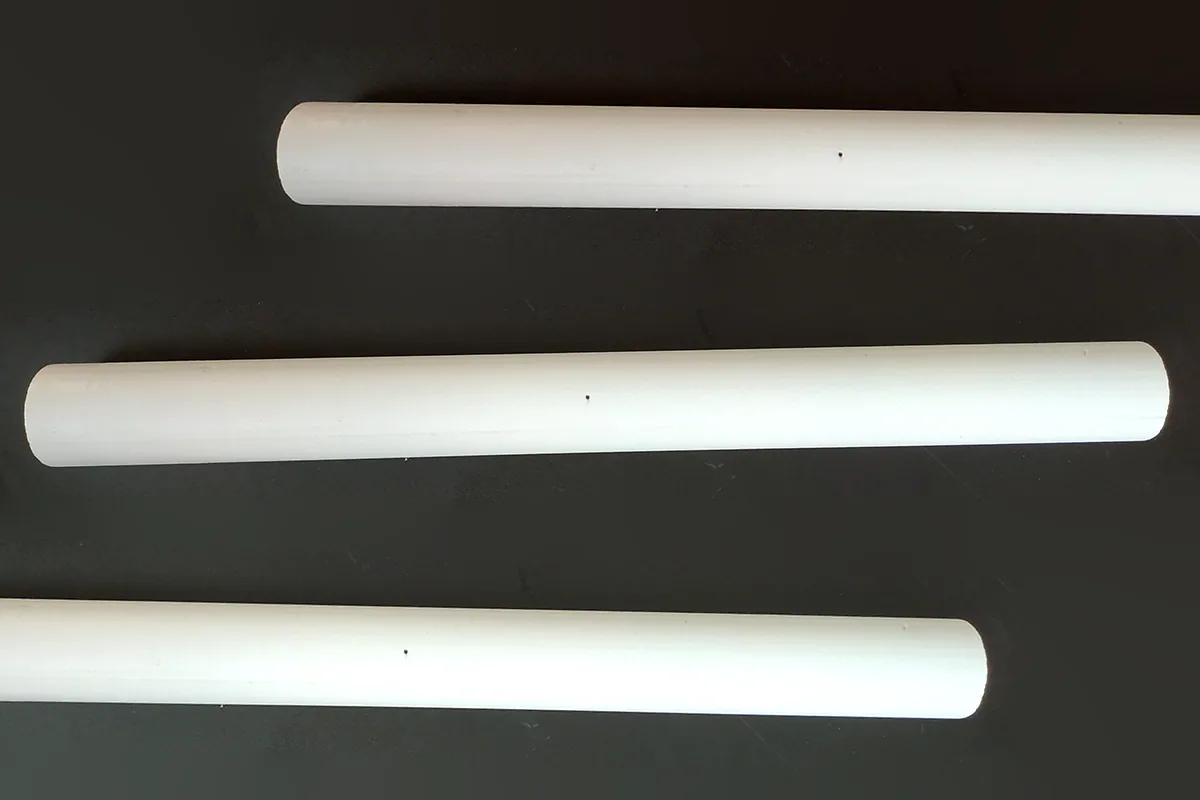

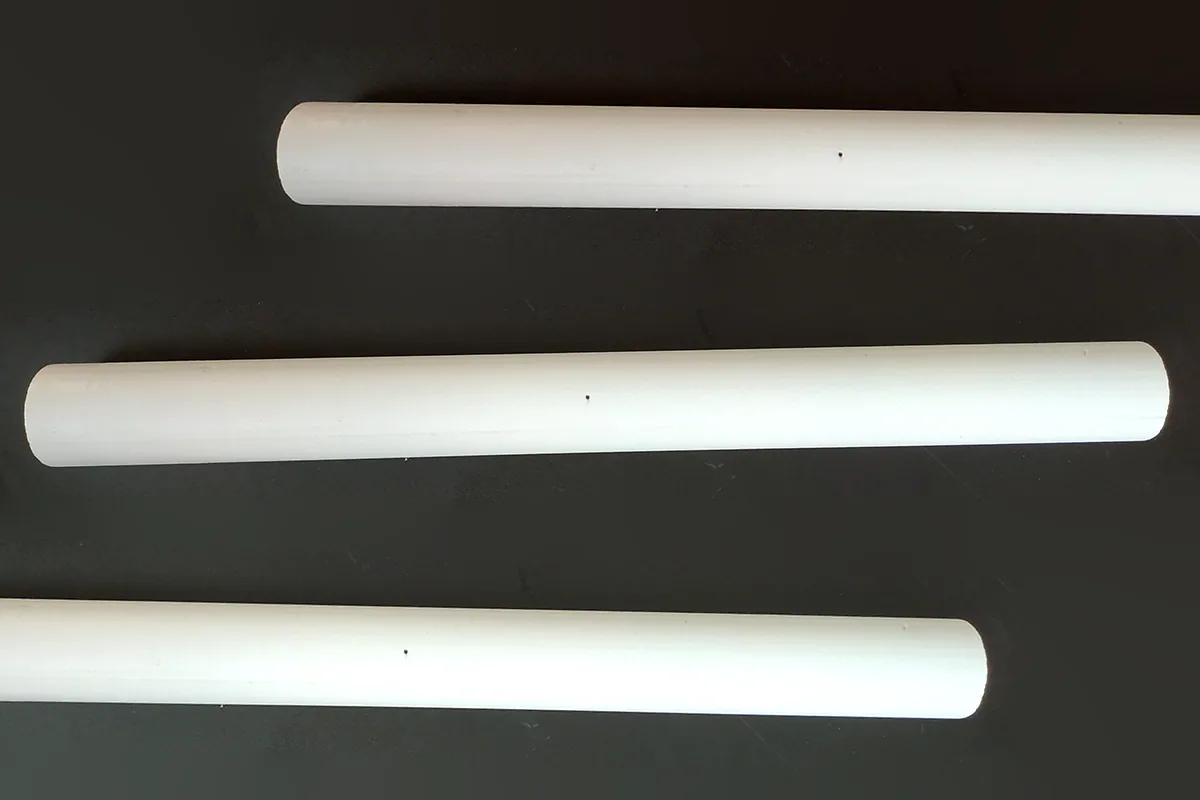

Mounting cylinder rod for ETICS

Subsequent fastening of medium-heavy loads can be carried out with the COMPACFOAM cylinder rod can be easily installed. After a hole has been made in the ETICS with the can drill, the cylinder rod is cut to the desired length and the hole is filled with COMPACFOAM. The attachment is made directly in the COMPACFOAM-mounting cylinder with standard wood screws. Pre-drilling is not necessary.

Thermal break façade systems

COMPACFOAM is used for the thermally separated installation of façade systems. Separation layers of 1-2 cm under brackets and mounting points significantly reduce heat loss through local thermal bridges. The bearings can be supplied prefabricated or cut from panels on site. Adaptations with milling to system components are possible without any problems.

Mounting bracket for hinged and sliding shutters in ETICS

Hinged shutters in particular exert incredible forces on the substructure. Elements must be permanently stable, pressure-resistant and, above all, well insulating. Even with very high façade insulation thicknesses, the COMPACFOAM mounting block meets these requirements. The mounting block is attached directly to the wall with adhesive as an element of the full thermal insulation. To attach the awning bracket, bolt anchors or a threaded rod are anchored through the mounting block into the load-bearing wall.

Mounting elements for awnings in ETICS

Increasing façade insulation thicknesses require new solutions for fixing awnings, as previous fixing systems usually only work up to an ETICS thickness of 160 mm. Installation should also be simple and free of thermal bridges. COMPACFOAM meets these requirements. You can COMPACFOAM in any desired format – ready-made as a mounting block or to cut to length yourself as a mounting rod. On request, we can take the hole pattern of the bracket into account.

Mounting elements for medium-heavy loads in ETICS

The installation of low-load components on the external thermal insulation composite system requires new fastening solutions with increasing insulation thicknesses. The COMPACFOAM-Mounting components are supplied either as rectangular blocks, rectangular bars or mounting elements adapted to the required geometry of the component. Bars can simply be cut to the required insulation thickness on site. Tensile forces can be transferred to the construction level (masonry, reinforced concrete, etc.) using steel anchors. For medium loads, installation can be carried out using standard wood screws without pre-drilling directly in COMPACFOAM take place.

Mounting elements for electrical sockets in ETICS

External sockets that are fixed in the ETICS are subject to particular stress: repeated tensile forces when disconnecting power cables usually cause the sockets to tear out after some time. The COMPACFOAM-The CF electrical mounting element (round or square) is firmly anchored to the masonry, while the socket itself is screwed into the CF element. This creates COMPACFOAM the perfect combination: fixed anchoring and yet a continuous thermal insulation composite system.

Mounting cylinder rod for ETICS

Subsequent fastening of medium-heavy loads can be carried out with the COMPACFOAM cylinder rod can be easily installed. After a hole has been made in the ETICS with the can drill, the cylinder rod is cut to the desired length and the hole is filled with COMPACFOAM. The attachment is made directly in the COMPACFOAM-mounting cylinder with standard wood screws. Pre-drilling is not necessary.

Tested at

References

Curtain wall façade

Mounting elements Insulation level

FAQ

The choice of the right material class depends primarily on the required screw pull-out strength and compressive strength. Larger screws generally allow the use of a lighter material class. Typical material classes are:

Window installation: CFeco and CF125

Sandwich cores for vehicle and furniture construction: CF200

Thermal break for steel structures: CF200, CF300, CF400

We are happy to support you in dimensioning and selecting the right material class to ensure that the solution is optimally tailored to your requirements. Do not hesitate to contact us if you have any questions or uncertainties!

Yes, COMPACFOAM is available in individual dimensions. The only limitation is usually the practical transport dimensions. Profiling and milling according to customer specifications are also possible.

Standard panels are available in all required thicknesses and strength classes. Cutting to size is easy with normal woodworking machines. Please use the saw blade recommended by us with a large tooth spacing. No substances harmful to health or the environment are produced during cutting.

The minimum dimensions are 6 mm thickness, 10 mm widthand the maximum dimensions are 500 mm thick, 1300 mm wide and 6000 mm long. Standard panels are also available for self-cutting.

All screws with a wood thread are suitable for installation. If there is sufficient space, a window frame screw with a diameter of 7.5 mm is recommended. Wood screws with a diameter of 4 mm are ideal for smaller components. Pre-drilling is not necessary and screws can also be used close to the edge without any problems.

COMPACFOAM has an unlimited shelf life under normal conditions. Moisture, water and frost do not affect the technical properties. UV radiation only has a minor superficial effect, meaning that even prolonged outdoor storage during the construction phase is unproblematic.