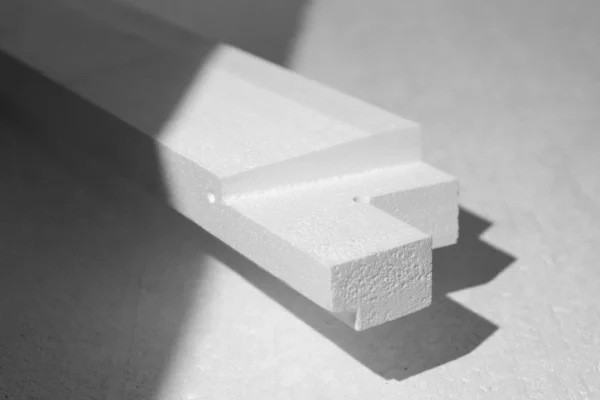

CNC milling - precise, economical & versatile

SKU: 3578

Category: CNC molded parts

Description & advantages

Use

Additional information

Data

The CF material classes differ primarily in terms of compressive strength, thermal conductivity and screw extraction. To determine the optimum material class for your application, please use the table in the Facts & Figures tab. We would also be happy to advise you personally.

Our material is also available in a sustainable version made from 100 % recycled material, the CFeco.

Advantages:

- High strength

- Excellent thermal insulation

- dimensionally stable

- without delay

- Powerful

- Moisture resistant

- climate resistant

- Easy to process

- 100% single-variety

- Sustainable

- Pollutant-free - without propellants, adhesives or fossil fuels

Areas of application:

- Window and facade construction

- Insulation profiles and supporting structures

- Lightweight construction and vehicle technology

- Mechanical engineering and custom-made products

Do you have special requirements? We realize tailor-made solutions according to your specifications!

Maximum dimensions:

- Length: up to 6000 mm

- Width: up to 1500 mm

- Thickness: up to 300 mm

- Tolerances of up to +/-0.2mm possible for maximum fitting accuracy

| Sintered highly compressed EPS | CF100 | CF125 | CF150 | CF200 | CF300 | CF400 | CF200eco | Standard | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sintered highly compressed EPS | Standard | |||||||||||||

| Compressive strength (N/mm2) | ||||||||||||||

| for 10% compression | 1,4 | 1,65 | 1,9 | 3,5 | 6,4 | 9,7 | 1,85 | EN 826 | ||||||

| for 2% compression | 0,8 | 1,1 | 1,32 | 1,48 | 3,24 | 4,0 | 0,98 | based on this | ||||||

| Permissible stress (N/mm2) with 2% long-term deformation and permanent load | 0,56 | 0,78 | 0,83 | 1,01 | 2,39*** | 4,18*** | 0,64 | internal | ||||||

| Screw extraction | ||||||||||||||

| Screw extraction* ⌀ 4.5mm (N) | 505 | 565 | 747 | 979 | 1729 | 2829 | - | internal | ||||||

| Screw extraction* ⌀ 7.5mm (N) | 837 | 919 | 1179 | 1875 | 2677 | 4047 | 825 | internal | ||||||

| in transverse direction** ⌀ 4.5mm (N) | 103 | 112 | 150 | 214 | 319 | 500 | - | internal | ||||||

| in transverse direction** ⌀ 7.5mm (N) | 296 | 394 | 493 | 542 | 1012 | 1333 | - | internal | ||||||

| Thermal conductivity | ||||||||||||||

| Rated value (W/mK) | 0,0387 | 0,0377 | 0,0423 | 0,0459 | 0,0531 | 0,0650 | 0,045 | EN 12667 | ||||||

| Density (kg/m3), +/- 10kg/m3 | 110 | 135 | 160 | 210 | 310 | 410 | 200 | internal | ||||||

| Water vapor diffusion resistance coefficient | ~25 | #colspan# | #colspan# | #colspan# | #colspan# | #colspan# | #colspan# | EN 12086-1 | ||||||

| Building material behavior in case of fire | E (B1) flame retardant | #colspan# | #colspan# | #colspan# | #colspan# | #colspan# | #colspan# | EN 13501-1, DIN 4102-1 | ||||||

| Max. Water absorption capacity 28 days | ~5% | #colspan# | #colspan# | #colspan# | #colspan# | #colspan# | #colspan# | EN 12087 | ||||||

* with 40 mm anchoring length

** with 1.5 mm max. head deformation, 40 mm anchoring length, 30 mm edge distance

*** 3% Long-term deformation