Window construction

Window sill connection insulation system

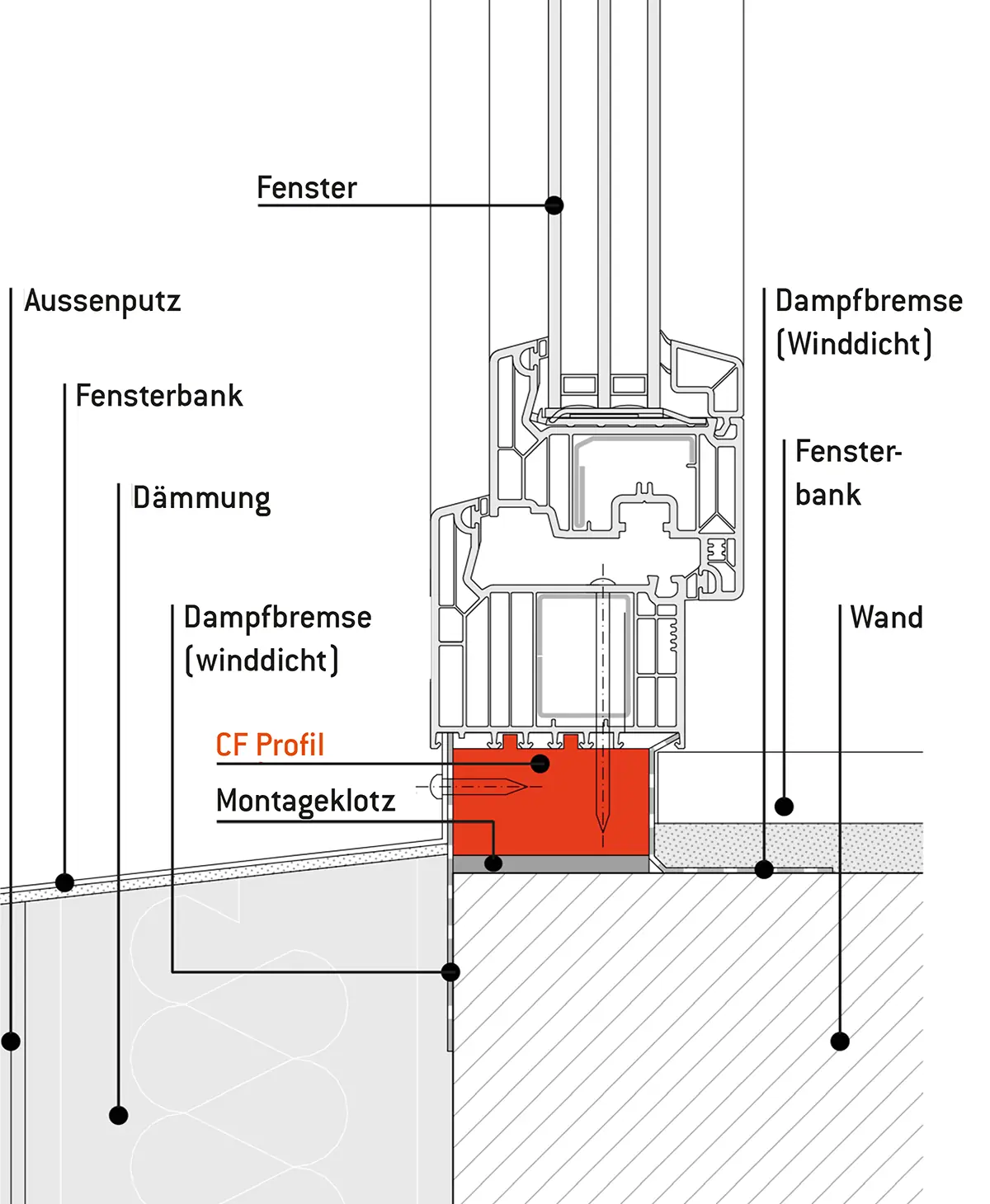

The CF window sill connection replaces conventional PVC window sill connection profiles. With the optimum lambda value of COMPACFOAM condensation and mold growth in the FBA area are a thing of the past. Due to the high strength of CF-FBA, the window sill can be fixed with special window sill screws without any problems. In conjunction with a PVC coating, the window sill can also be fixed with standard window sill screws.

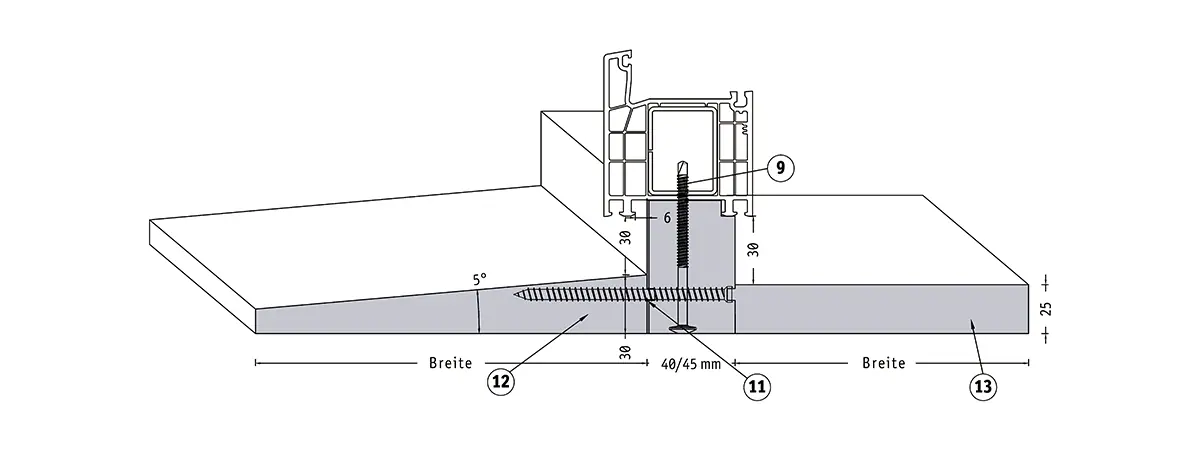

The CF insulating wedge offers a simple and reliable formation of the second sealing level. Due to the high lambda value of COMPACFOAM dangerous thermal bridges are reliably avoided. The inclination of the window sill to the front is ensured at 5°.

Optionally, the inside of the CF window sill Interior insulation board The 25 mm height of the internal insulation board ensures that the internal window sill is adequately underlaid.

The COMPACFOAM-The window sill connection insulation system consists of three parts:

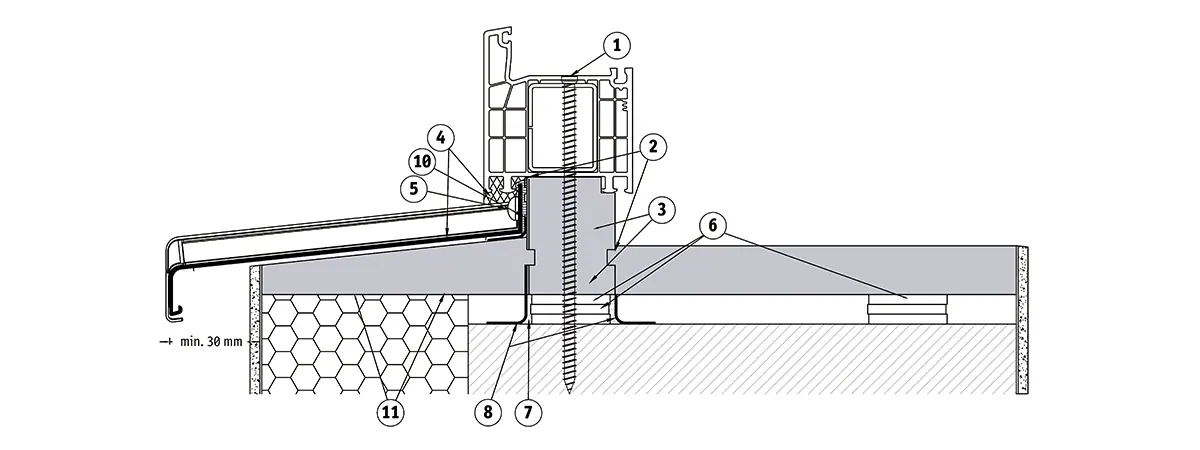

Details

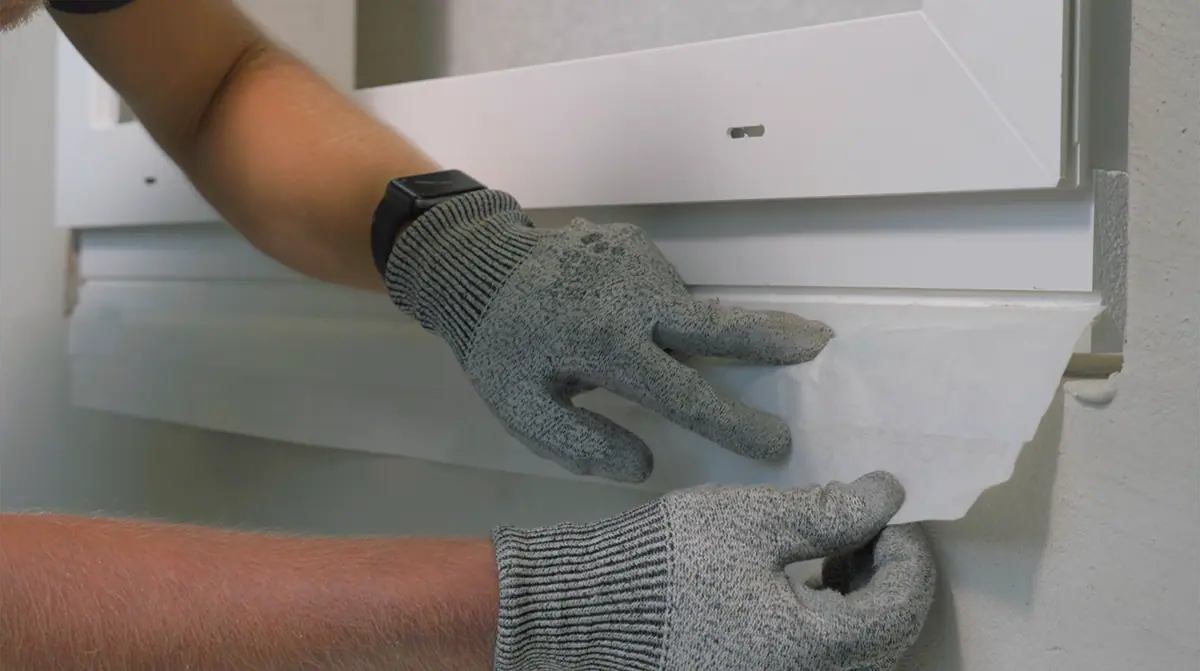

Installation variant with CF insulating wedge

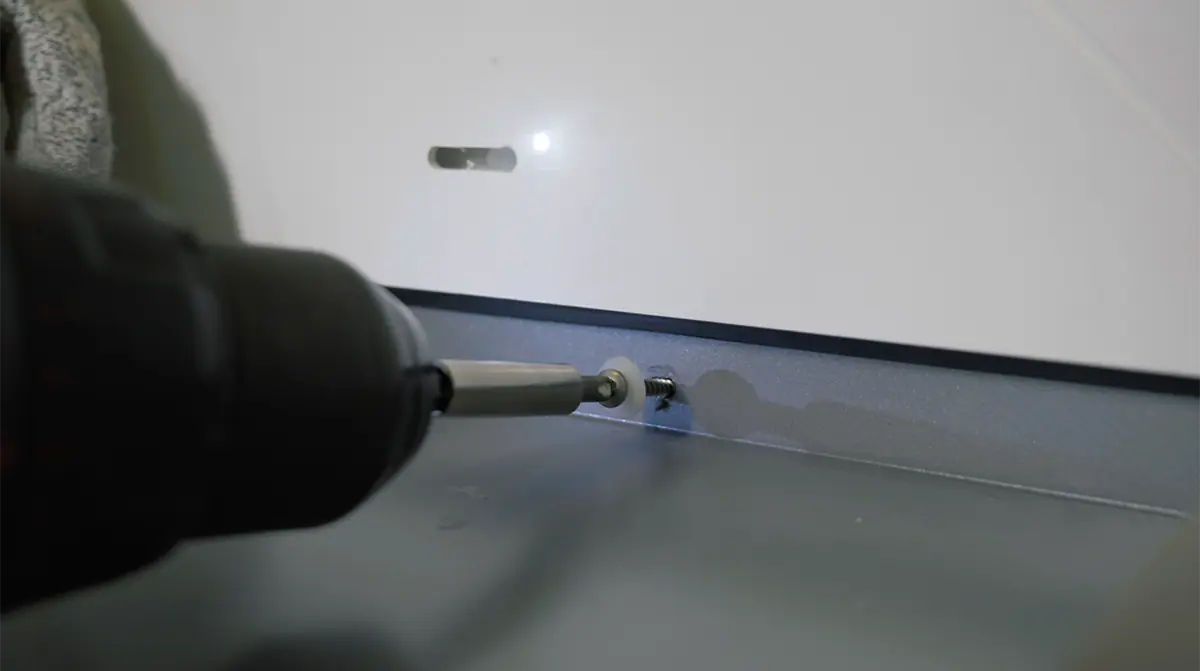

- Window frame screw 7.5mm - no pre-drilling required in the window sill connection profile; spacing and anchoring length according to static requirements or RAL guideline

- Joint bonding with MS polymer adhesive or adhesive tape

- CF window sill connection profile (CF-FBA)

- The trade hole must be permanently sealed in accordance with the state of the art

- Window frame screw

- Shims

- Joint insulation according to the state of the art

- Sealing inside and outside according to the state of the art

- Screw 5.5mm (see mounting variant 2)

- Window sill

- Joint bonding with MS polymer

- CF insulating wedge 5° (see installation variant 2)

- Internal insulation board (see installation variant 2)

Profile cut

The COMPACFOAM-window sill connection insulation system is flexible in every respect:

- The individual parts are not only available in the standard length, but also in special lengths.

- The height and depth of the FBA profile can be freely selected. Due to the COMPACFOAMproduction process, we can produce any cross-section, even in very small quantities, at low cost.

- There are no limits when it comes to profiling. Individual tools are not absolutely necessary, which allows us to produce any desired profile. We supply the individual FBA profile for YOUR window.

- On request, the FBA profile can be provided with a PVC coating on one or both sides.

- The insulation wedge and the interior insulation board can also be customized. This applies not only to the dimensions, but also to whether or not you want a tongue and groove plug-in connection.

You can achieve maximum flexibility by purchasing panels from which you can cut and profile the FBA profiles yourself in your workshop.

to the productsDue to the high strength of CF-FBA, the window sill can also be fixed with special window sill screws without any problems. In conjunction with the PVC surface, the window sill can also be fixed with standard window sill screws. Pre-drilling in COMPACFOAM is not required.

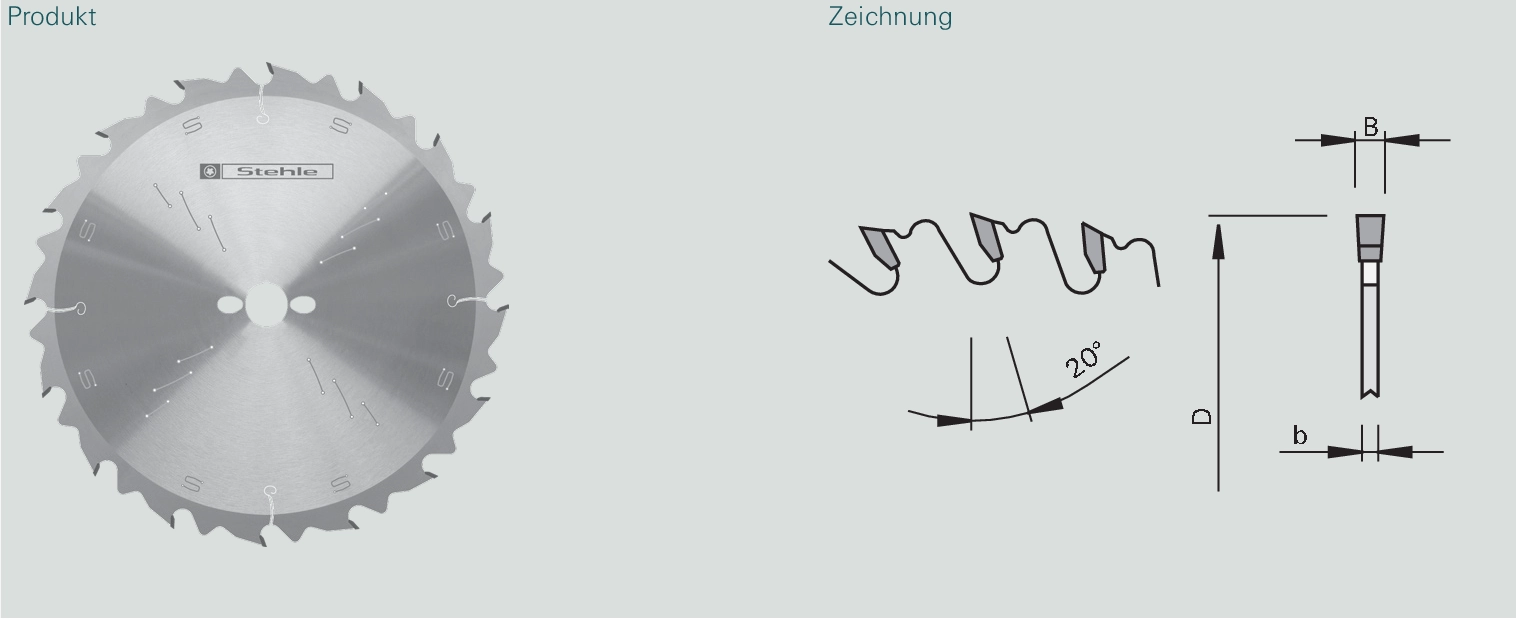

COMPACFOAM can be easily cut to size using commercially available saws such as circular saws, pressure beam saws or hand-held circular saws. It is important to use saw blades with a wide tooth spacing and free chip space.

For the cutting of COMPACFOAM we recommend saw blades with flat teeth and chip thickness limiter and very large tooth pitch. Optimum cutting results are achieved at 2000 rpm.

Saw blade recommendation

Thermal insulation: Window sill connection

COMPACFOAM FBA profiles replace conventional PVC window sill connection insulation profiles. The optimum lambda value of COMPACFOAM leads to a lower U-value for windows without thermal bridges.

Technical data

* any thickness available

With the help of a newly developed process, particle technology, we can reduce the waste of COMPACFOAM recycle to 100 %. CFeco200, the result of this process, offers the same good properties as COMPACFOAMhigh strength with excellent thermal insulation.

COMPACFOAM FBAs can also be ordered in the CFeco200 recycling version.

In any case, you increase the proportion of recycled materials in construction and improve the eco-balance of your project and company. Because environmental protection means keeping things in circulation instead of disposing of them at great expense.