Window construction

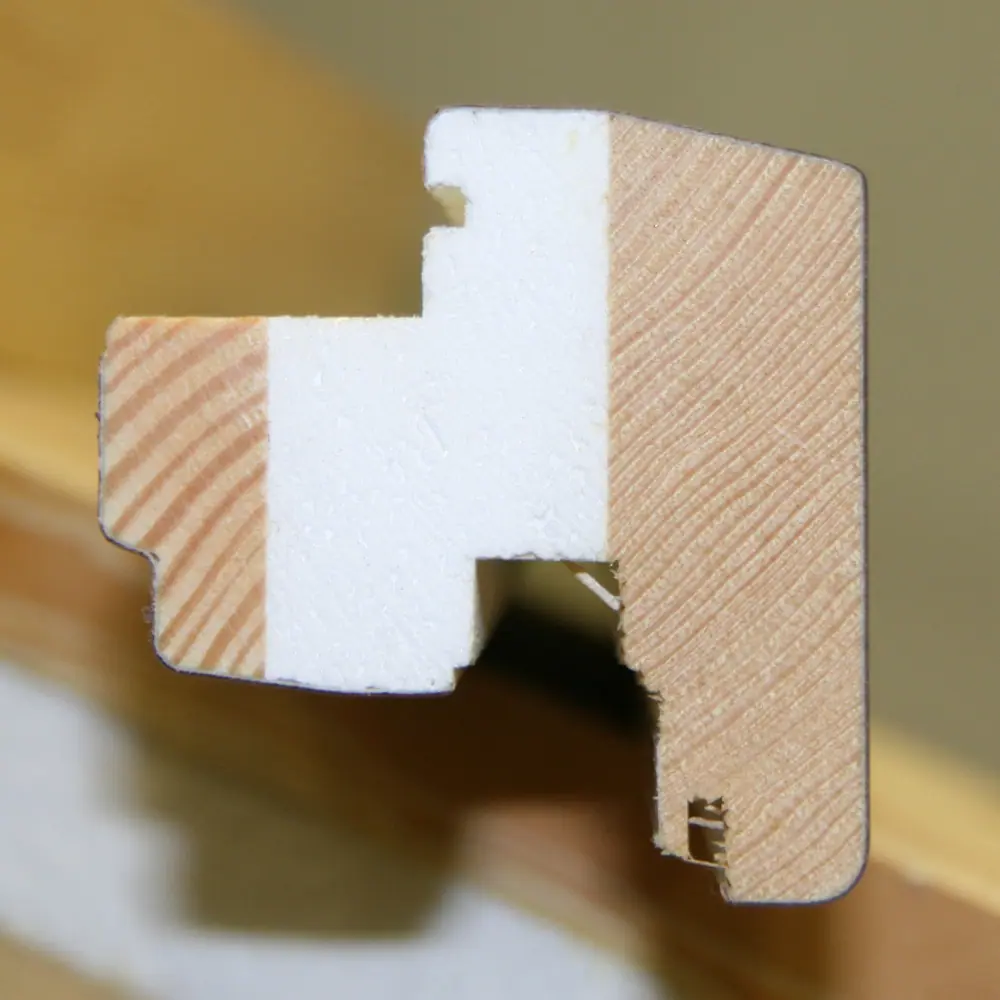

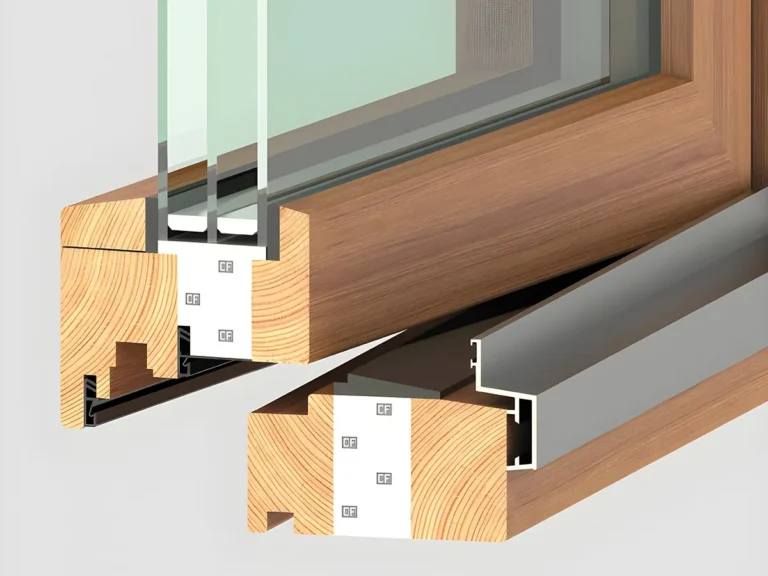

CF insulation core for window scantlings

With the COMPACFOAMinsulation core, energy-optimized window scantlings with maximum thermal insulation can be produced.

The CF insulation core is characterized by its high dimensional and compressive stability. It is also available in any cross-section. Window scantlings with the CF insulating core can be processed using standard woodworking machines.

Request nowAdvantages

Details

In addition to ready-made bars in width and height, we also supply whole panels in the desired thickness. These offer you even greater flexibility to cut the bars to size yourself in your own workshop.

Apart from the standard length (2350mm), you can order any other length up to 6m from us.

In conjunction with COMPACFOAM, screw fittings that reach into the middle layer of a scantling are no longer an issue. It is also possible to screw aluminum cladding fastenings for timber/aluminium windows directly into COMPACFOAM.

With the help of a newly developed process, particle technology, we can reduce the waste of COMPACFOAM recycle to 100 %. CFeco200, the result of this process, offers the same good properties as COMPACFOAMhigh strength with excellent thermal insulation.

This increases the proportion of recycled materials in construction and improves the eco-balance of your project and company. Because environmental protection means keeping things in circulation instead of disposing of them at great expense.