Window construction

Substructure for lift and slide systems

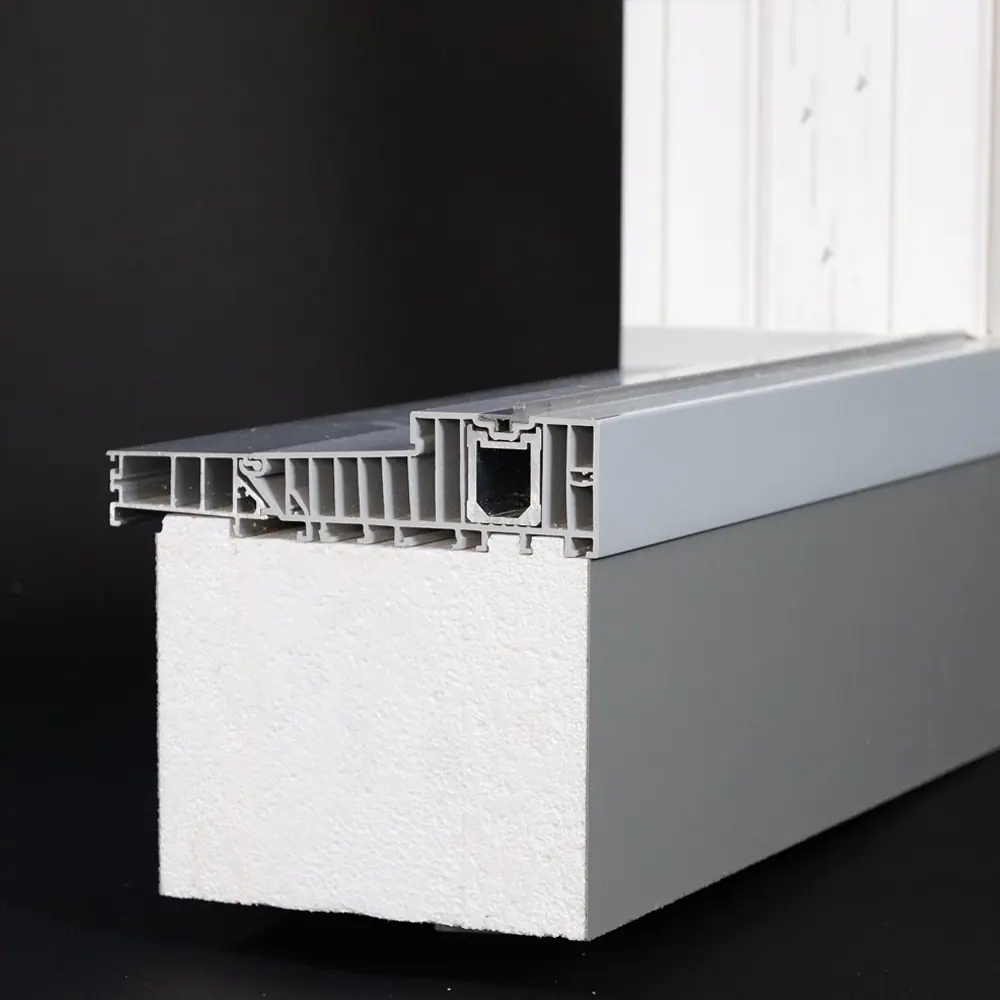

The trend towards ever larger lift-and-slide systems leads to correspondingly higher weights that have to be transferred to the substructure insulating profile.

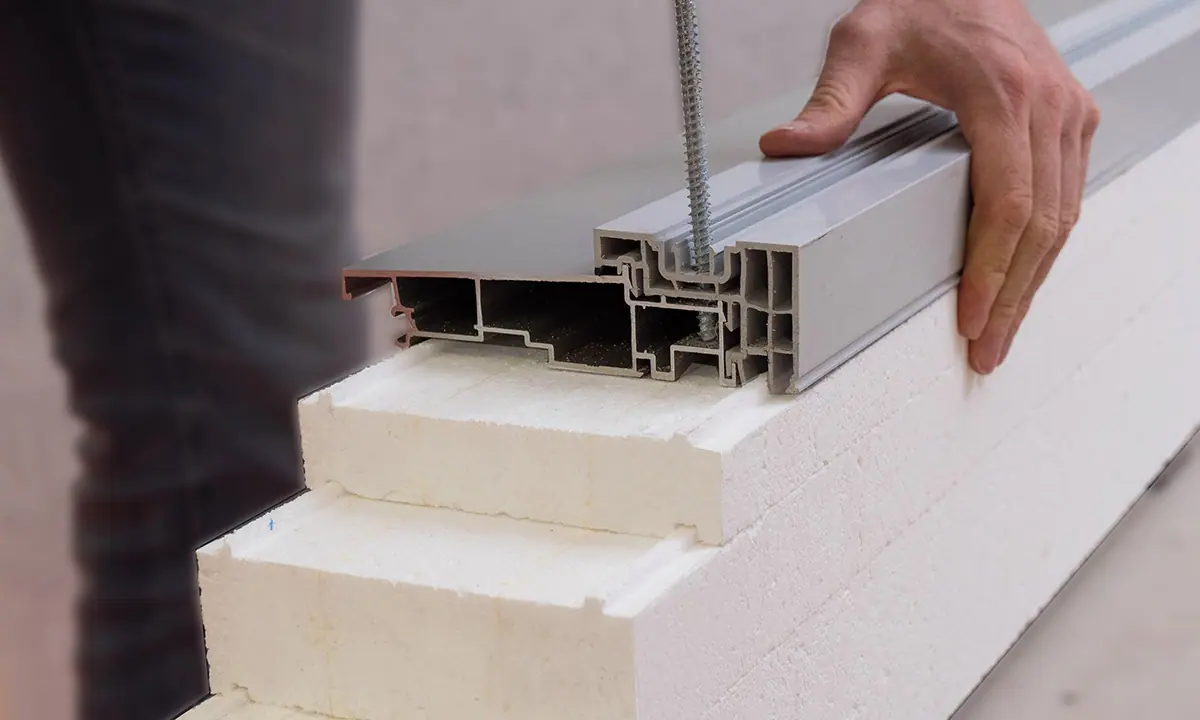

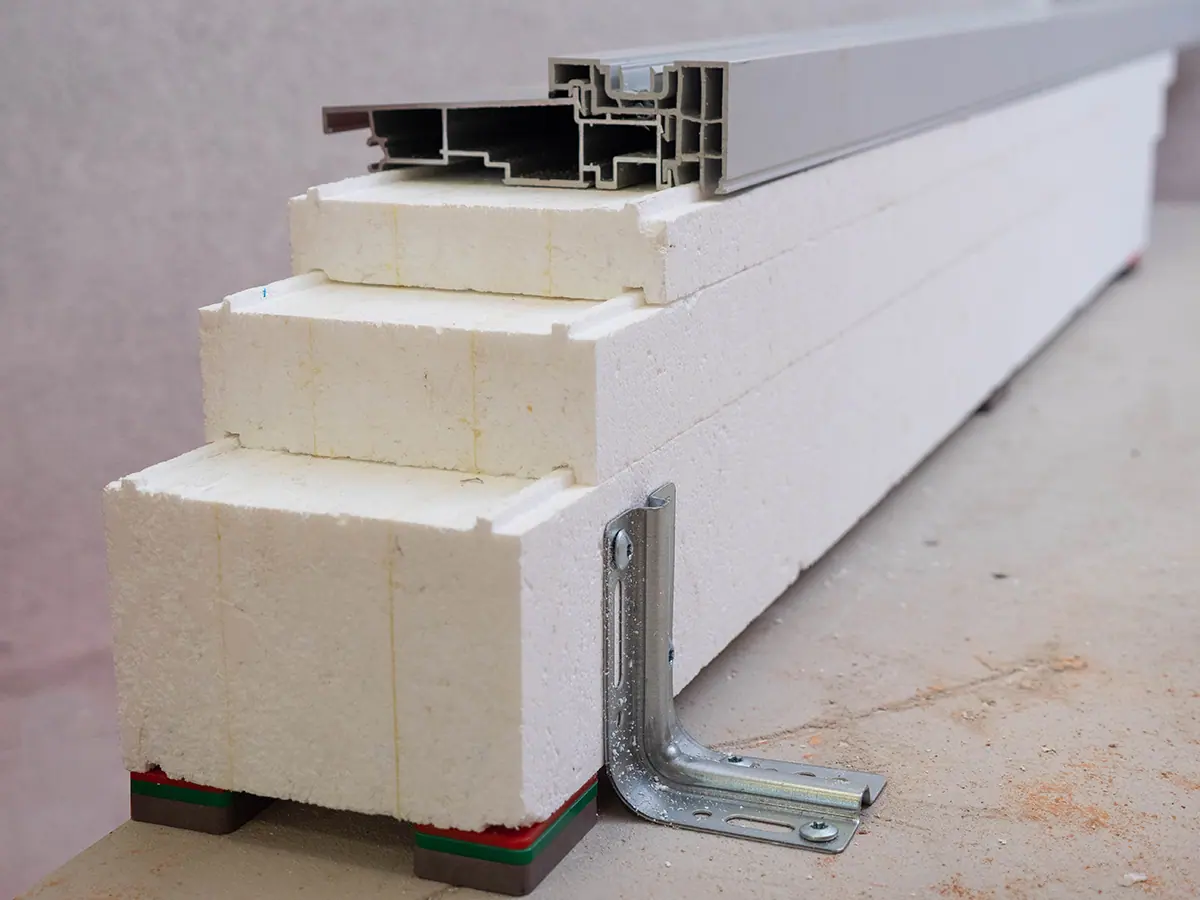

The lift and slide substructure combines strength and excellent thermal insulation thanks to two load-bearing layers and an insulating core with a very low dead weight. Thanks to the two thick load-bearing layers on the inside and outside, screw connections can be made from above and below without any problems. The forces are thus easily transferred into the masonry.

Economical and safe

Details

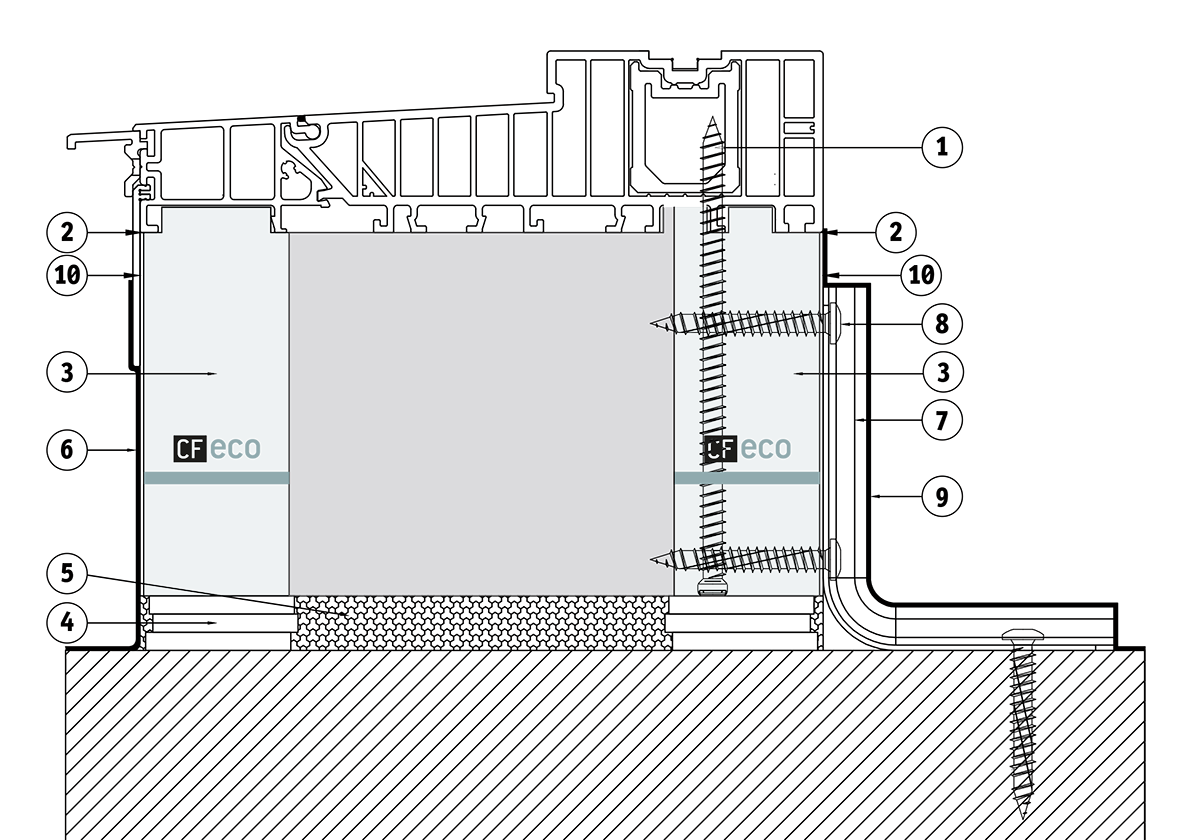

Installation variant with highly insulating substructure insulating profiles suitable for all lift and slide door thresholds.

- Window frame screw 7.5mm - no pre-drilling required in the substructure profile; spacing and anchoring length according to static requirements or RAL guidelines

- Joint bonding with MS polymer adhesive or adhesive tape

- Base courses 40mm CFeco

- Shims

- Joint insulation according to the state of the art

- State-of-the-art external waterproofing, e.g. liquid plastic according to suitability list, bitumen membrane

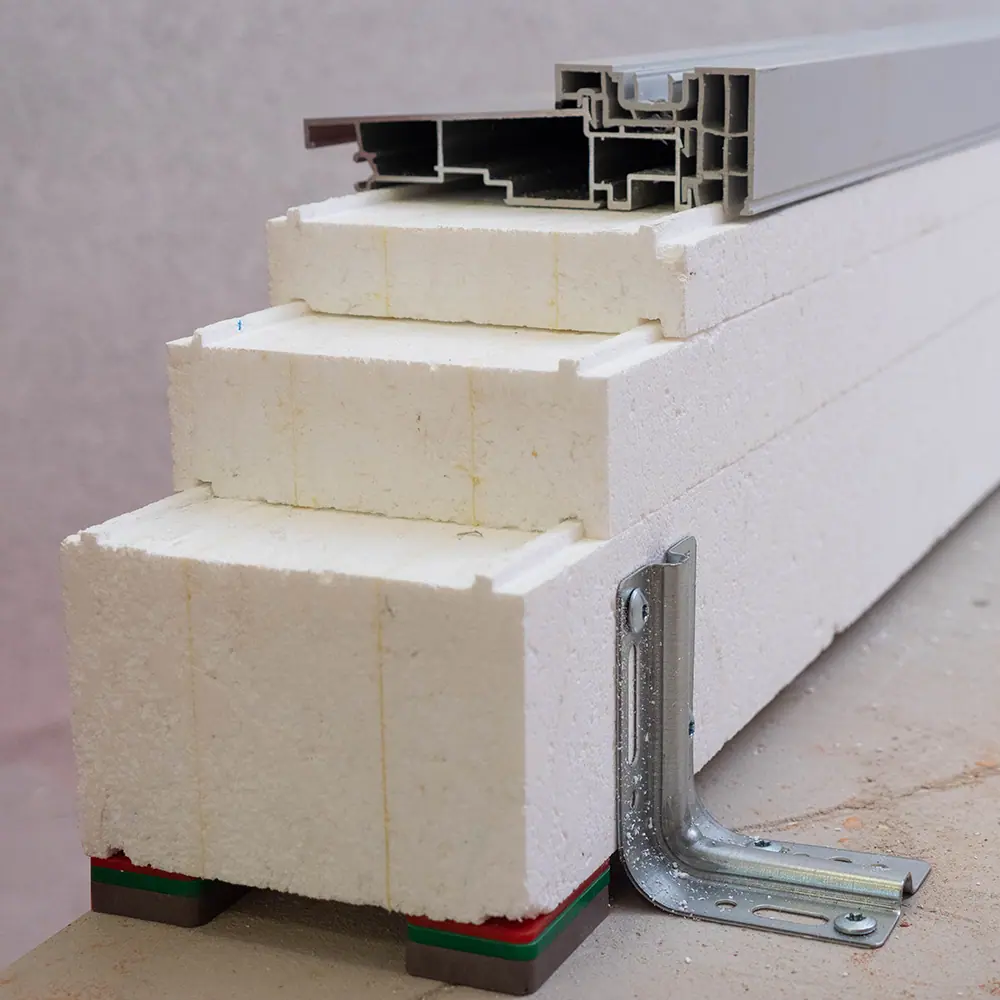

- Mounting bracket according to statics

- Window frame screw 7.5mm flat head

- Sealing inside according to the state of the art

- PVC top layer

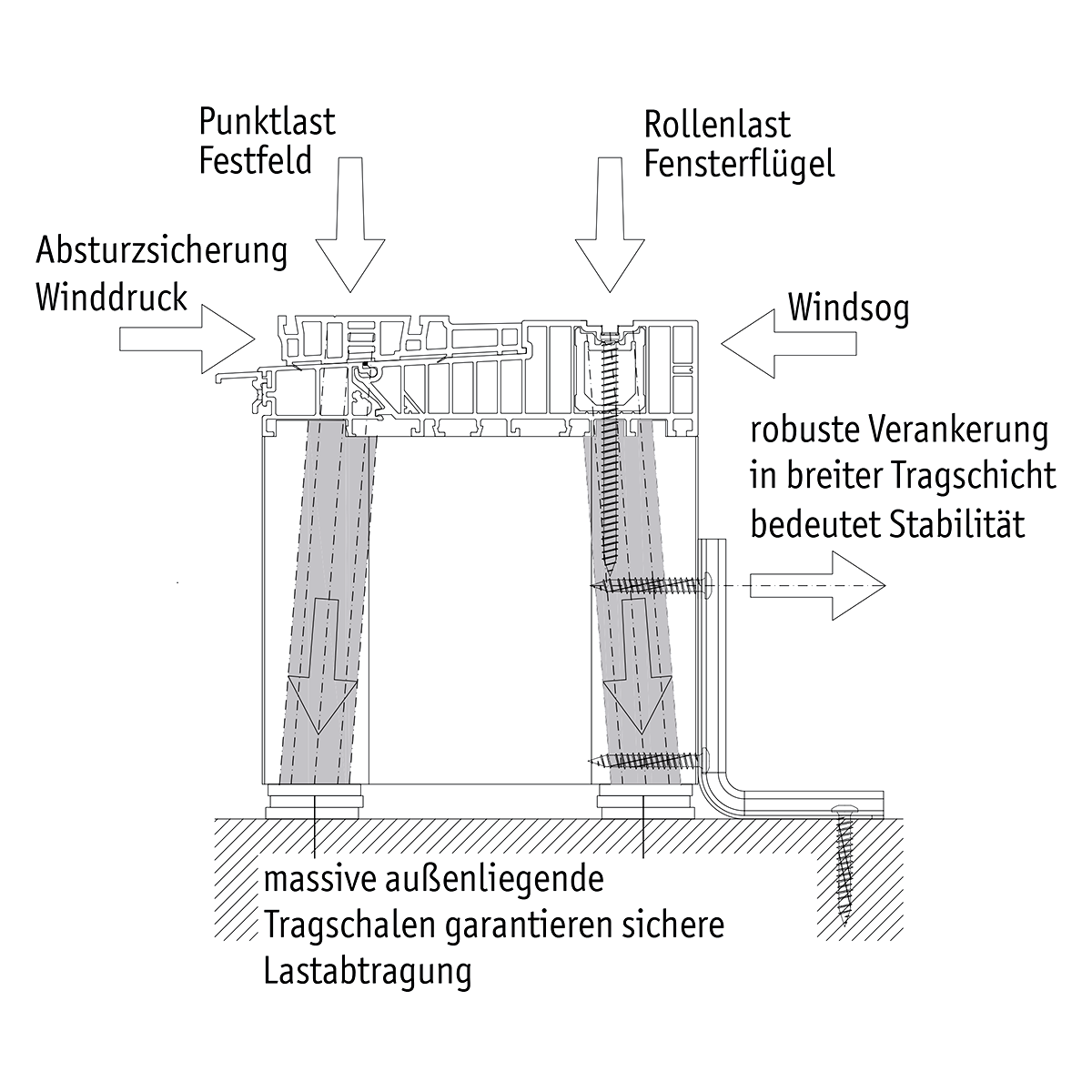

- The two solid load-bearing layers on the inside and outside safely transfer the heavy weight of lift and slide doors into the building structure.

- The mounting bracket can also be robustly screwed into the wide base layers.

- Wind pressure, wind suction and ETB forces are absorbed by the counter-milling and the mounting bracket.

Dimensions:

Surfaces:

Profiling:

Dimensions

COMPACFOAM Substructure insulation profiles are not only available in the standard length of 2350mm, but also in any desired length up to 6m.

Coating

On request, the substructure can be provided with a PVC coating on one or both sides.

Flexibility

You can achieve maximum flexibility by purchasing panels that you cut and profile yourself in your workshop.

Profiling/contour

There are no limits when it comes to profiling. Individual tools are not absolutely necessary, which allows us to profile even small quantities cost-effectively. We supply the individual substructure for YOUR lift and slide door.

The stacking contour (tongue and groove plug-in connection) allows different stand-off heights to be achieved flexibly.

In addition, processing with our CNC 5-axis milling machine is possible up to 4700x600x300mm in one piece for highly complex and individual requirements.

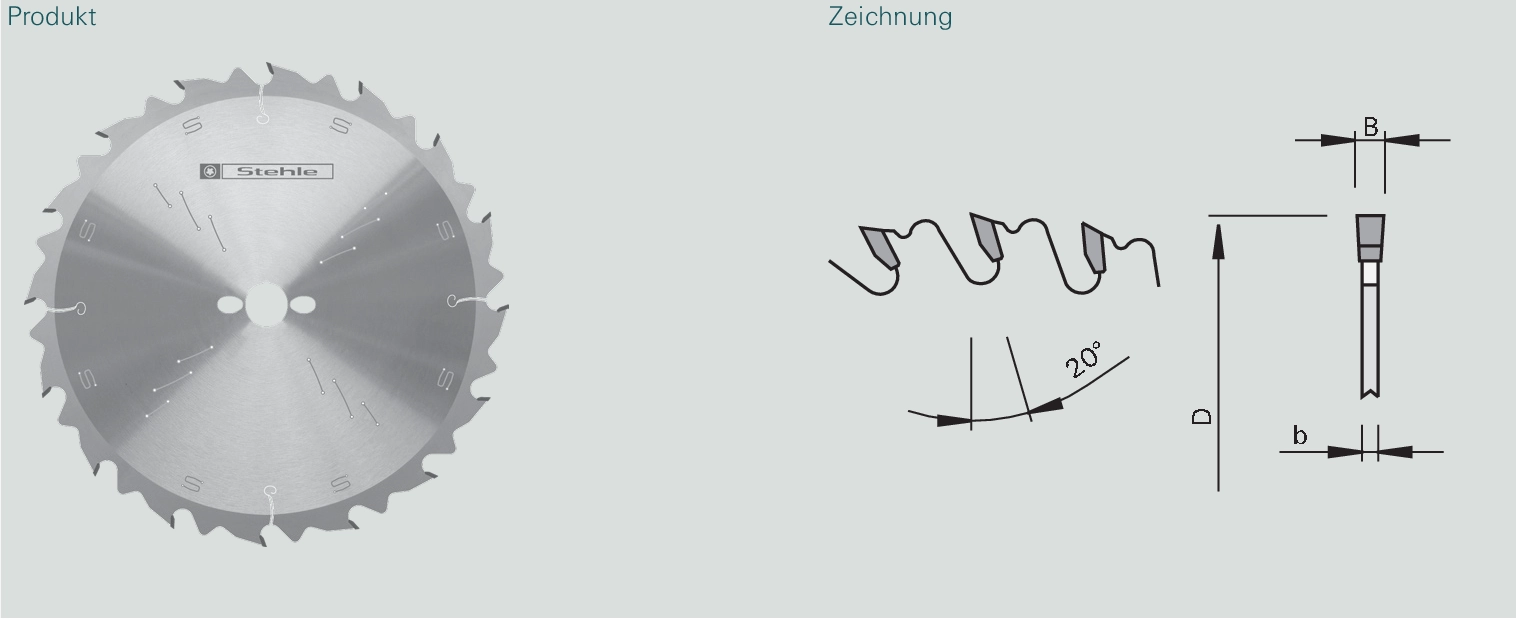

COMPACFOAM can be easily cut to size using commercially available saws such as circular saws, pressure beam saws or hand-held circular saws. It is important to use saw blades with a wide tooth spacing and free chip space.

For the cutting of COMPACFOAM we recommend saw blades with flat teeth and chip thickness limiter and very large tooth pitch. Optimum cutting results are achieved at 2000 rpm.

Saw blade recommendation

With the help of a newly developed process, particle technology, we can reduce the waste of COMPACFOAM recycle to 100 %. CFeco200, the result of this process, offers the same good properties as COMPACFOAM: high strength with excellent thermal insulation.

The two base layers of the COMPACFOAM-Sliding substructures are produced in CFeco200 as standard. This means you are using a substructure system that is largely made from recycled material. If you opt for the solid core version (substructure without insulating core), you can even work with a substructure made from 100 % recycled material.

In any case, you increase the proportion of recycled materials in construction and improve the eco-balance of your project and company. Because environmental protection means keeping things in circulation instead of disposing of them at great expense.

1. air and water tightness

2. assembly of the substructure

3. installation

4. external sealing

The following materials can be used for sealing:

Waterproofing with a bituminous membrane is also possible if carried out correctly.

Further information on sealing can be found here.

To the data sheet