COMPACFOAM - the perfect solution for window construction

Thermally insulating, stable, screwable & moisture-resistant

Secure and economical window installation with high load-bearing capacity and thermal break.

Discover now

Efficient solutions for modern window construction

In window construction, thermal bridge-free connections and high load-bearing capacity are essential. Traditional materials often reach their limits when stability and thermal insulation have to be combined.

COMPACFOAM is the solution: high strength, excellent insulation and low weight. Ideal for pre-wall installations, window sill connections, substructure insulation profiles and frame extensions.

With COMPACFOAM you build energy-efficient and durable. High load-bearing capacity and easy processing make it the economical choice for window construction.

Applications in window construction

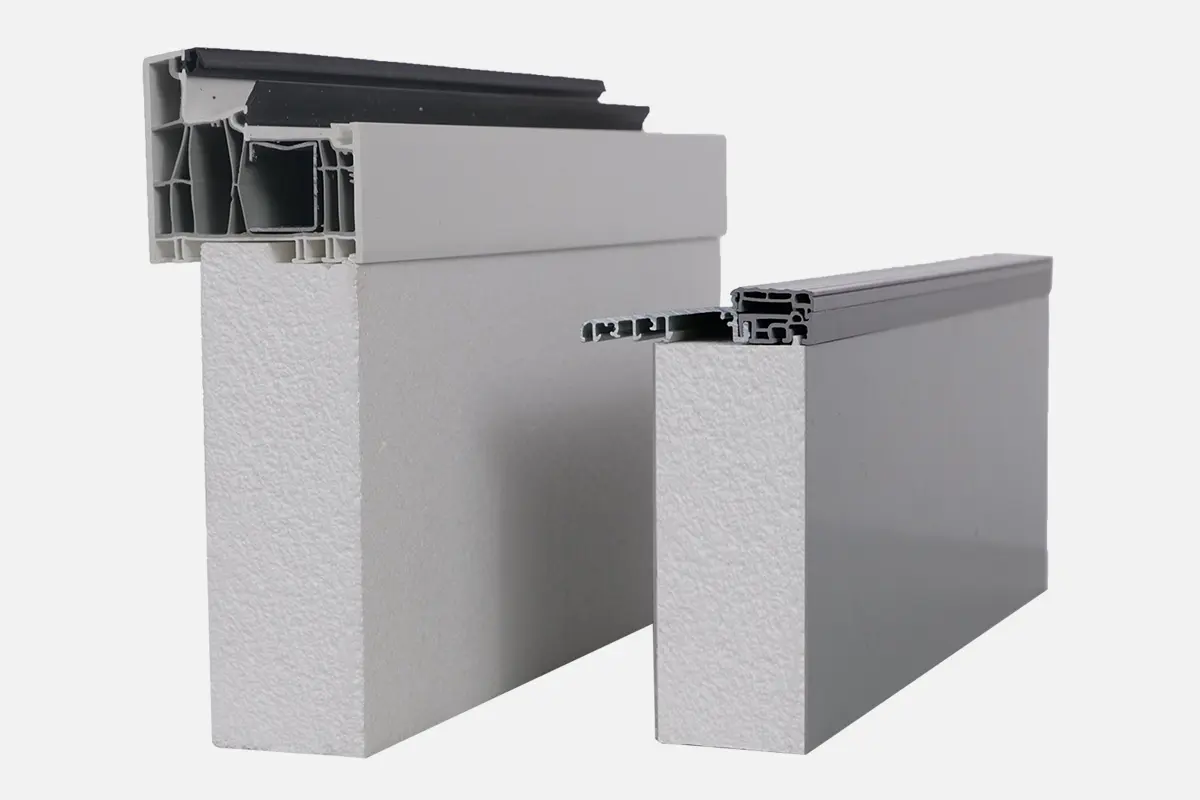

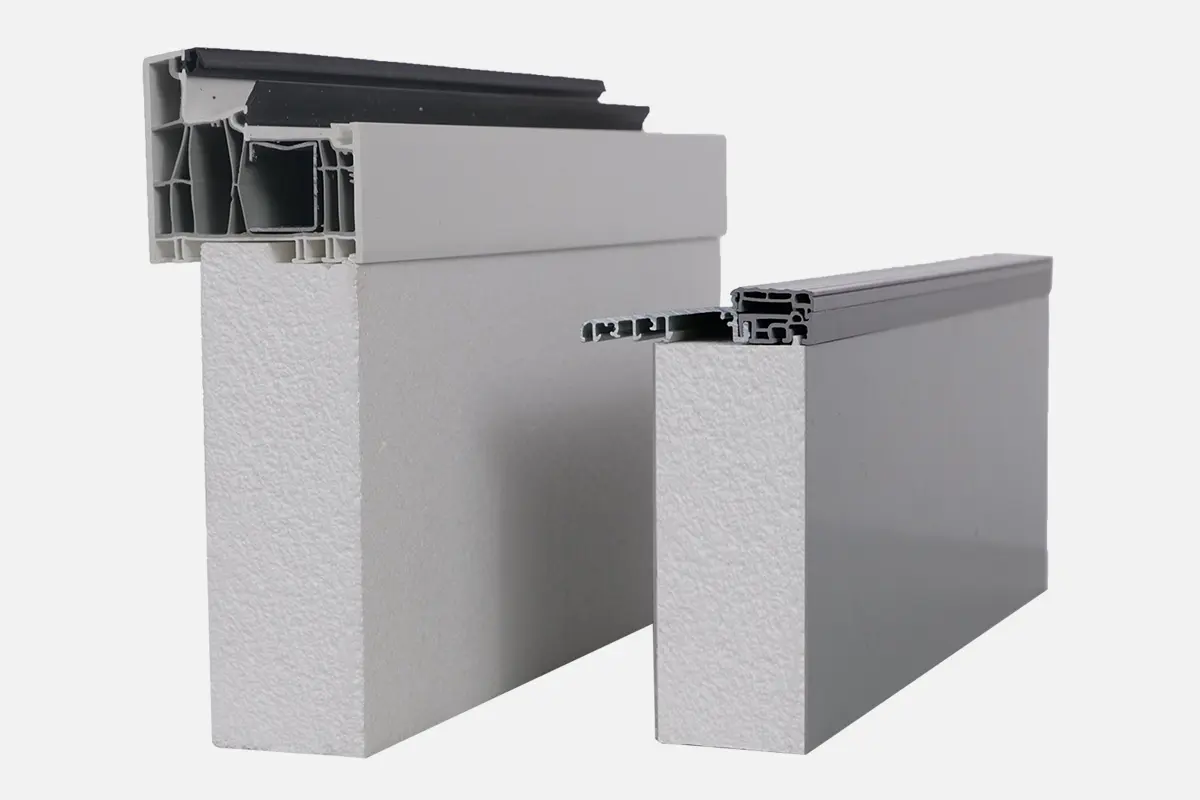

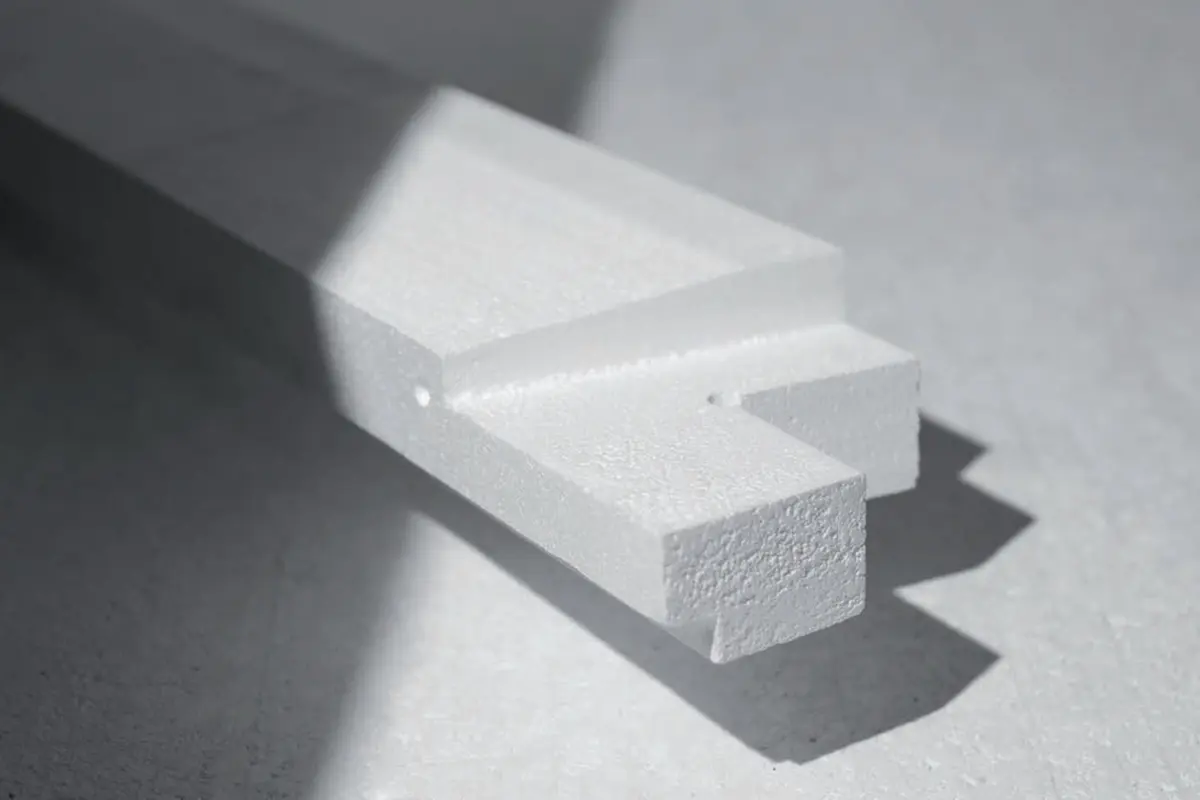

Substructure insulating profile (UDP)

The CF substructure insulating profile combines strength with excellent thermal insulation and a very low dead weight. With the UDP, you can ensure the desired floor clearance for patio doors, front doors and windows. The stable and waterproof construction material means that it can be fixed from all sides.

More information

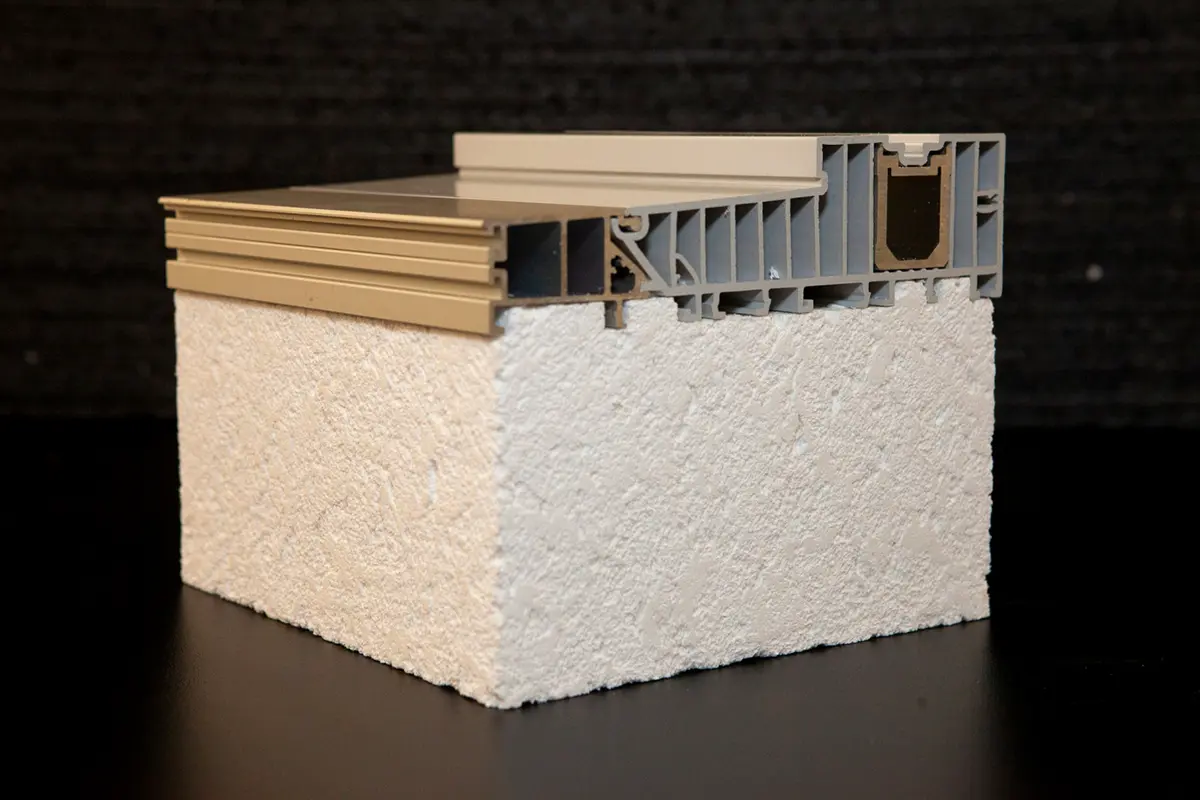

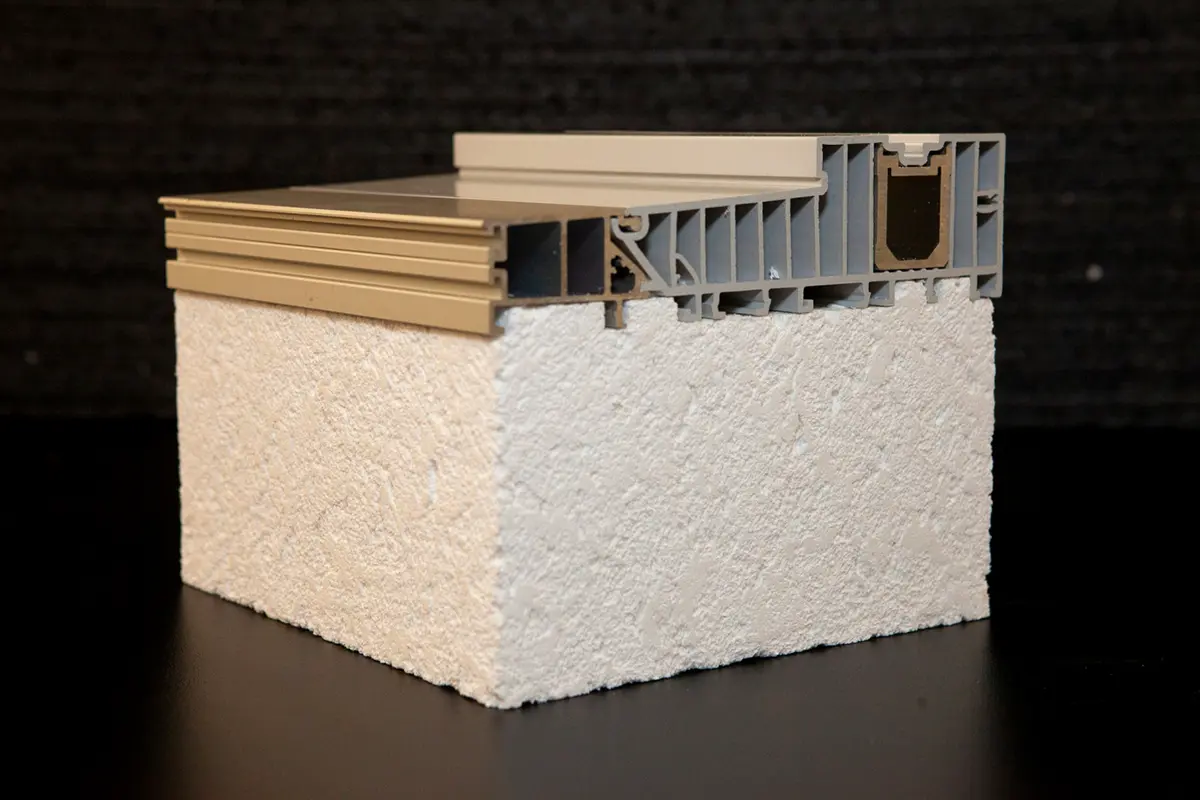

Lift and slide substructure

The HS substructure combines strength with two load-bearing layers and an insulating core with excellent thermal insulation and a very low dead weight. Thanks to the two thick load-bearing layers on the inside and outside, it can be screwed together from above and below without any problems.

More information

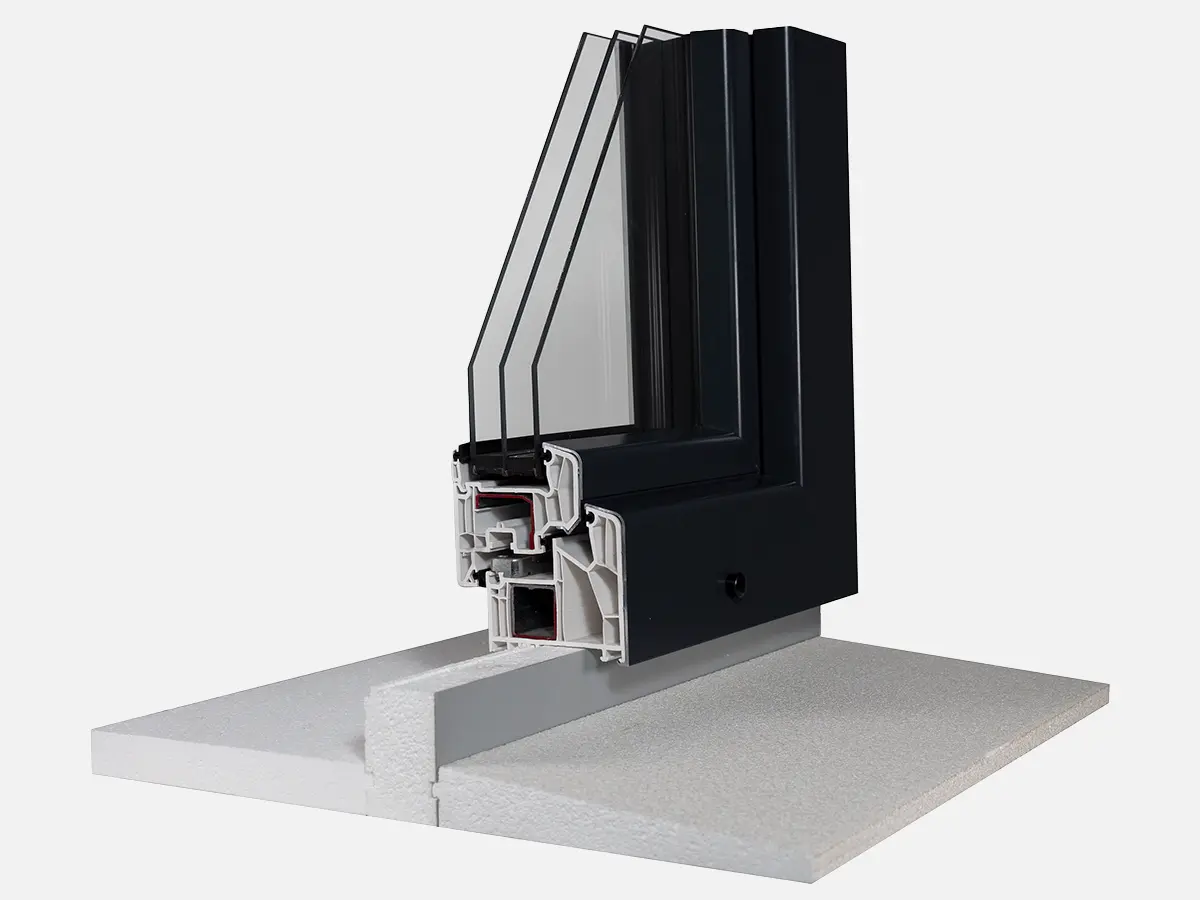

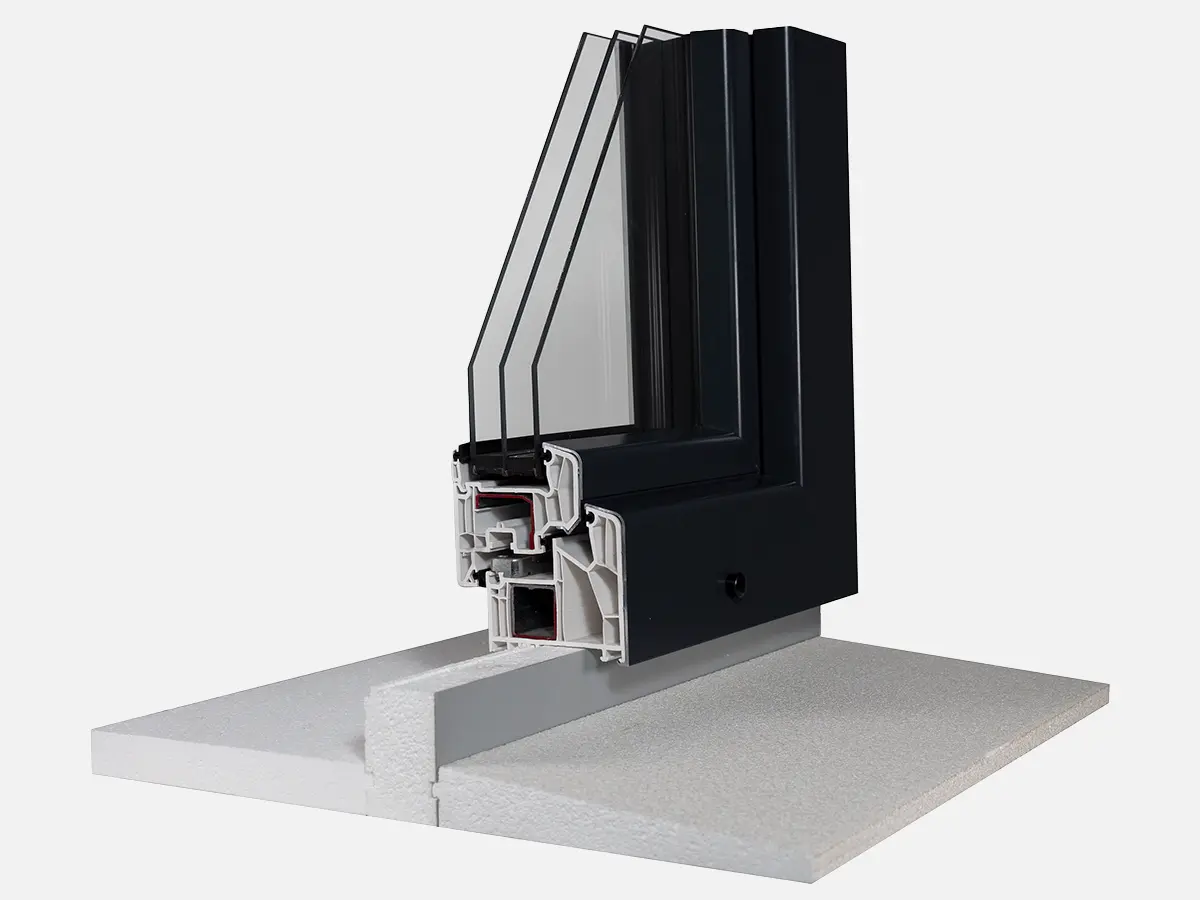

Pre-wall installation (climate compliant)

With the CF-Klima Konform system, windows and doors can be installed in the insulation level (ETICS) without thermal bridges. This means that the windows and doors move to the outside of the thermal insulation.

More information

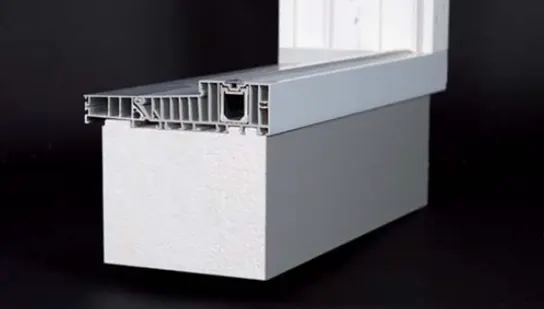

Window sill connection insulation system (FBA)

The CF window sill connection insulation system consists of the CF window sill connection (FBA), the CF insulation wedge for underlining the external window sill and the CF internal insulation board. The CF-FBA replaces conventional PVC profiles. With the optimum lambda value of COMPACFOAM condensation and mold growth are a thing of the past. Due to the high strength, the window sill can be fixed with special window sill screws without any problems. Standard window sill screws can also be used in conjunction with a PVC surface.

More information

Frame widening

The CF frame widening profile combines high strength with excellent thermal insulation and low dead weight. It enables secure widening for windows, doors and façade elements. Thanks to the stable, waterproof construction material, fixing is possible from all sides.

Door panels

The CF construction core is thermally stabilized so that there is no swelling and shrinkage due to changes in temperature and humidity. It is insensitive to moisture, temperature and frost, yet is open to diffusion and breathable. This is particularly important when in contact with wood.

More information

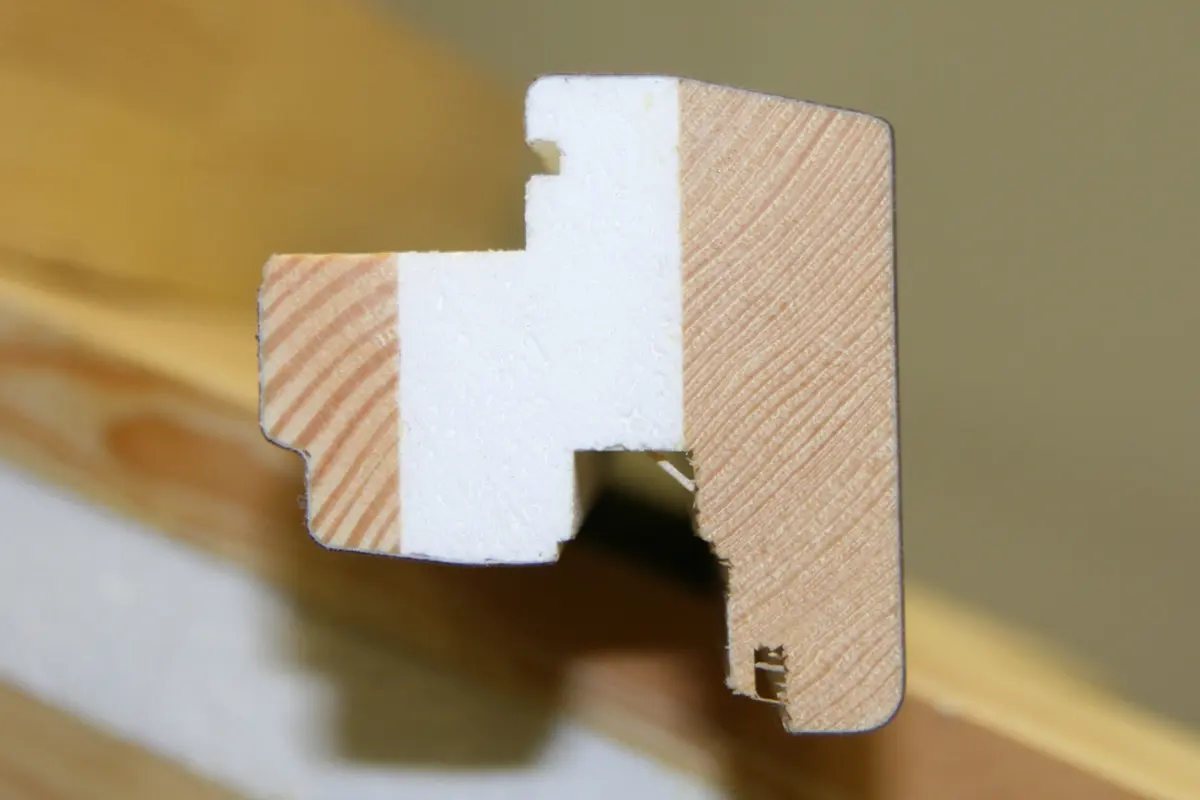

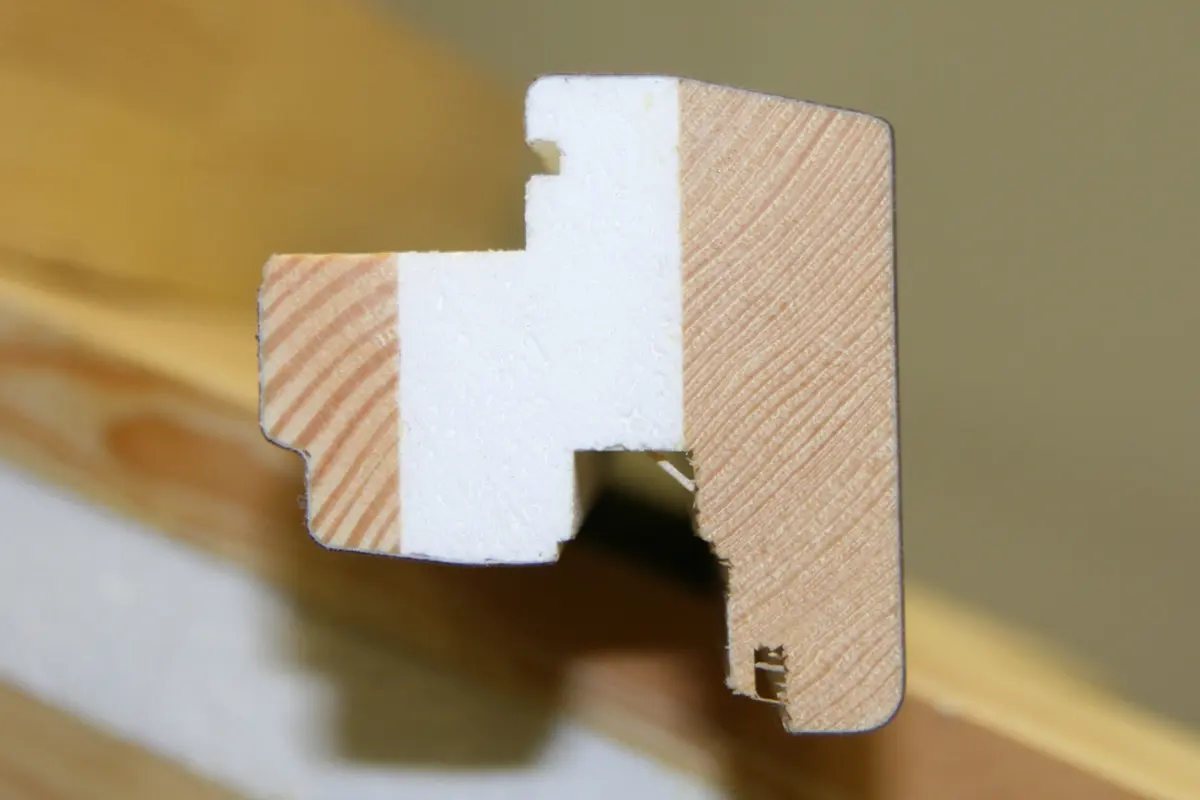

Window scantlings

The CF insulation core can be used to produce energy-optimized window scantlings with maximum thermal insulation. The CF insulation core is characterized by its high dimensional and compressive stability. It is also available in any cross-section. Window scantlings with the CF insulating core can be processed using standard woodworking machines.

More information

Components for high-performance window systems

Special designs in window construction require solutions with high strength and thermal insulation. COMPACFOAM replaces several components thanks to these properties and simplifies construction. Thanks to its high diffusion openness, it is ideal for contact with wood and its precision and dimensional stability make it particularly suitable for crimp and clamp connections on aluminum systems.

Request

Substructure insulating profile (UDP)

The CF substructure insulating profile combines strength with excellent thermal insulation and a very low dead weight. With the UDP, you can ensure the desired floor clearance for patio doors, front doors and windows. The stable and waterproof construction material means that it can be fixed from all sides.

More information

Lift and slide substructure

The HS substructure combines strength with two load-bearing layers and an insulating core with excellent thermal insulation and a very low dead weight. Thanks to the two thick load-bearing layers on the inside and outside, it can be screwed together from above and below without any problems.

Pre-wall installation (climate compliant)

With the CF-Klima Konform system, windows and doors can be installed in the insulation level (ETICS) without thermal bridges. This means that the windows and doors move to the outside of the thermal insulation.

Window sill connection

The CF window sill connection insulation system consists of the CF window sill connection (FBA), the CF insulation wedge for underlining the external window sill and the CF internal insulation board. The CF-FBA replaces conventional PVC profiles. With the optimum lambda value of COMPACFOAM condensation and mold growth are a thing of the past. Due to the high strength, the window sill can be fixed with special window sill screws without any problems. Standard window sill screws can also be used in conjunction with a PVC surface.

Door panels

The CF construction core is thermally stabilized so that there is no swelling and shrinkage due to changes in temperature and humidity. It is insensitive to moisture, temperature and frost, yet is open to diffusion and breathable. This is particularly important when in contact with wood.

Window scantlings

The CF insulation core can be used to produce energy-optimized window scantlings with maximum thermal insulation. The CF insulation core is characterized by its high dimensional and compressive stability. It is also available in any cross-section. Window scantlings with the CF insulating core can be processed using standard woodworking machines.

Components for high-performance window systems

Special designs in window construction require solutions with high strength and thermal insulation. COMPACFOAM replaces several components thanks to these properties and simplifies construction. Thanks to its high diffusion openness, it is ideal for contact with wood and its precision and dimensional stability make it particularly suitable for crimp and clamp connections on aluminum systems.

Highly resilient

Climate stable

Recyclable

Excellent thermal insulation

Diversity

Machinable

Delivery forms

Perfect for pre-wall installations, window and door insulation, and much more.

Perfect for window sill connections, substructures, frame extensions, pre-wall installations and much more.

Perfect for window sill connections, insulation wedges, shutter covers and much more.

Perfect for substructures of lift and slide doors.

Composite parts

Perfect for door cores

Cores for sandwich production

Screws, adhesive, brackets for mounting COMPACFOAM Elements

Our partners

References

Pre-wall installation

Substructure profiles

Window sill connection

Components for window systems

Components for window systems

FAQ

The choice of the right material class depends primarily on the required screw pull-out strength and compressive strength. Larger screws generally allow the use of a lighter material class. Typical material classes are

Window installation: CFeco and CF125

Sandwich cores for vehicle and furniture construction: CF200

Thermal break for steel structures: CF200, CF300, CF400

We are happy to support you in dimensioning and selecting the right material class to ensure that the solution is optimally tailored to your requirements. Do not hesitate to contact us if you have any questions or uncertainties!

Yes, COMPACFOAM is available in individual dimensions. The only limitation is usually the practical transport dimensions. Profiling and milling according to customer specifications are also possible.

Standard panels are available in all required thicknesses and strength classes. Cutting to size is easy with normal woodworking machines. Please use the saw blade recommended by us with a large tooth spacing. No substances harmful to health or the environment are produced during cutting.

The minimum dimensions are 6 mm thickness, 10 mm widthand the maximum dimensions are 500 mm thick, 1300 mm wide and 6000 mm long. Standard panels are also available for self-cutting.

All screws with a wood thread are suitable for installation. If there is sufficient space, a window frame screw with a diameter of 7.5 mm is recommended. Wood screws with a diameter of 4 mm are ideal for smaller components. Pre-drilling is not necessary and screws can also be used close to the edge without any problems.

COMPACFOAM has an unlimited shelf life under normal conditions. Moisture, water and frost do not affect the technical properties. UV radiation only has a minor superficial effect, meaning that even prolonged outdoor storage during the construction phase is unproblematic.