FENSTERBAU

CLIMATE FRIENDLY STRUCTURAL INSULATION.

ECONOMICAL AND STURDY.

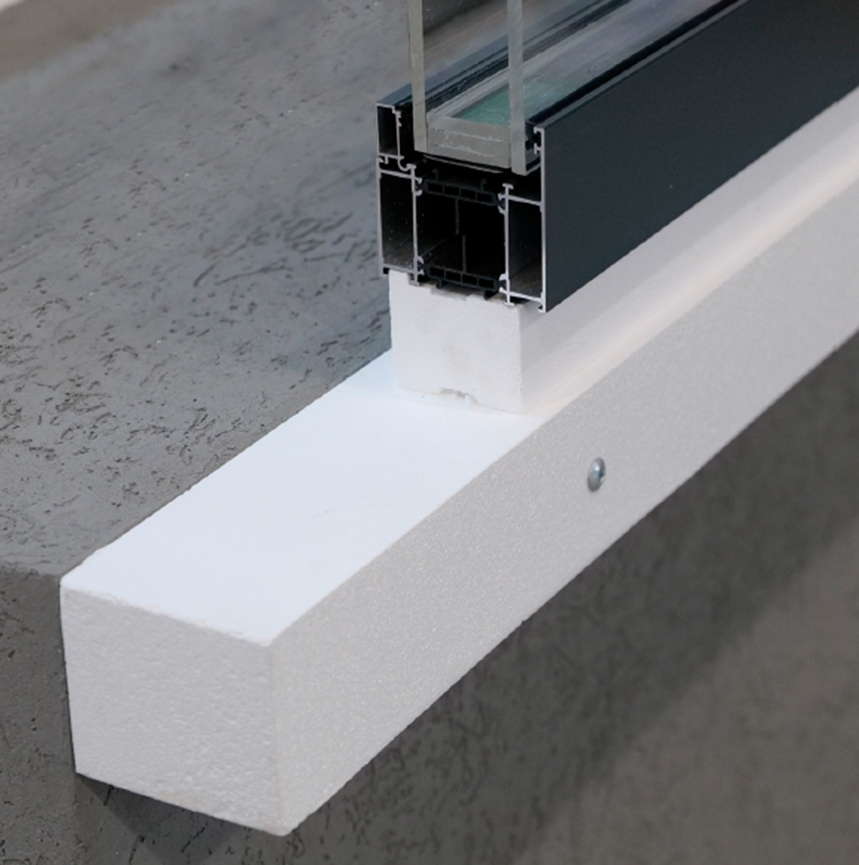

With the COMPACFOAM Frame Support system, windows and doors can be installed in the external insulation layer and avoid thermal bridges. This means that the windows and doors are installed beyond the solid outer walls into the external wall thermal insulation. This method is known as pre-wall mounting.

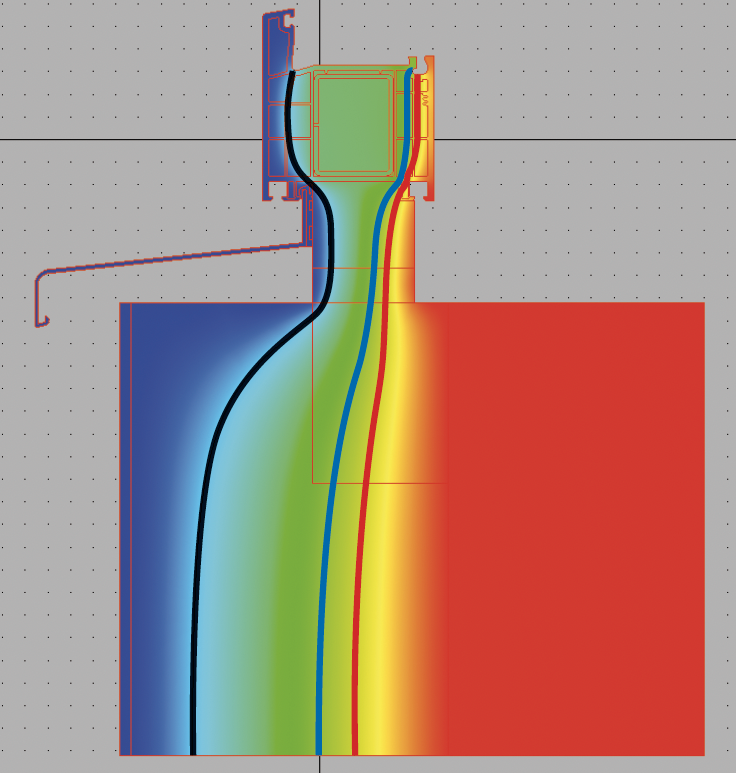

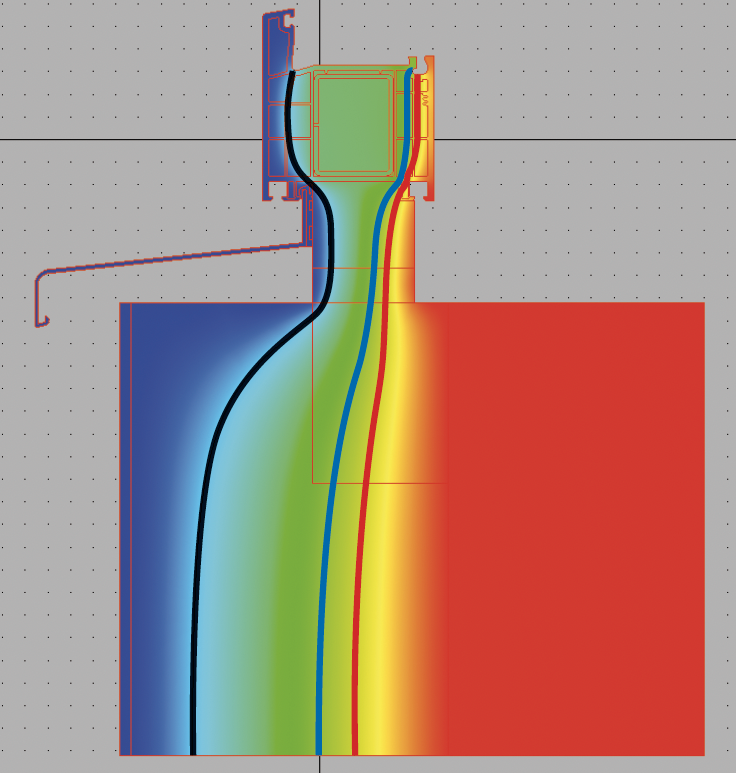

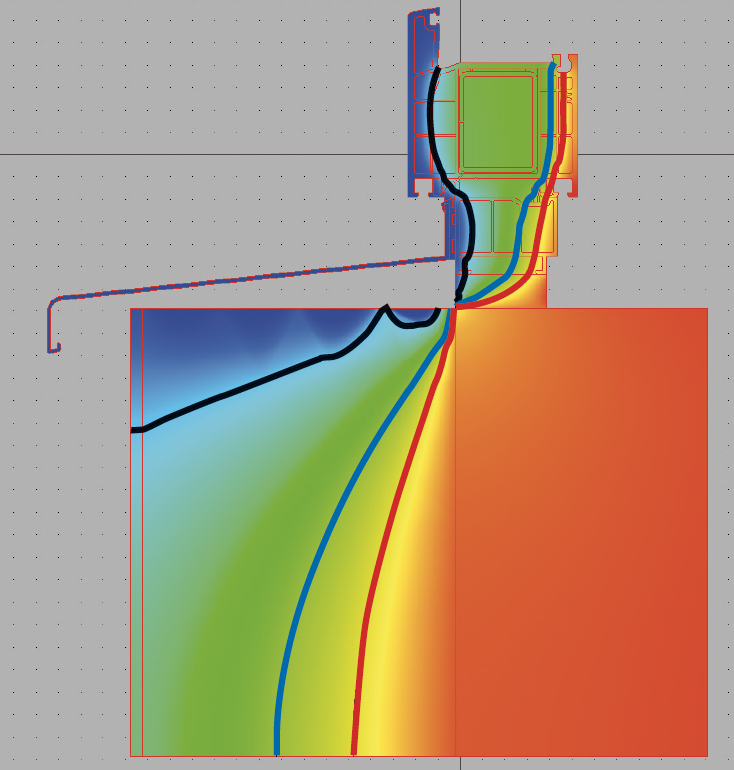

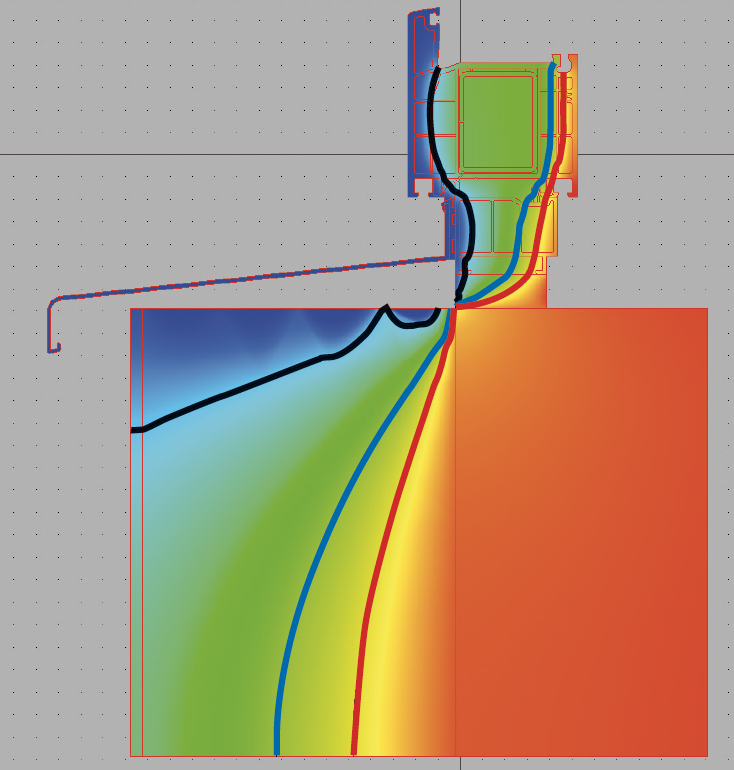

Fixing windows and doors in the insulation layer has several advantages; the building is more aesthetically pleasing from outside and the position lets more light into the building. Deeper reveals inside allow more room for inward opening windows. More light means more solar energy and the solar heat gaining. The isothermal curves in the transition bet- ween the window and the wall system show how the cold temperatures are kept to the outside fabric of the building.

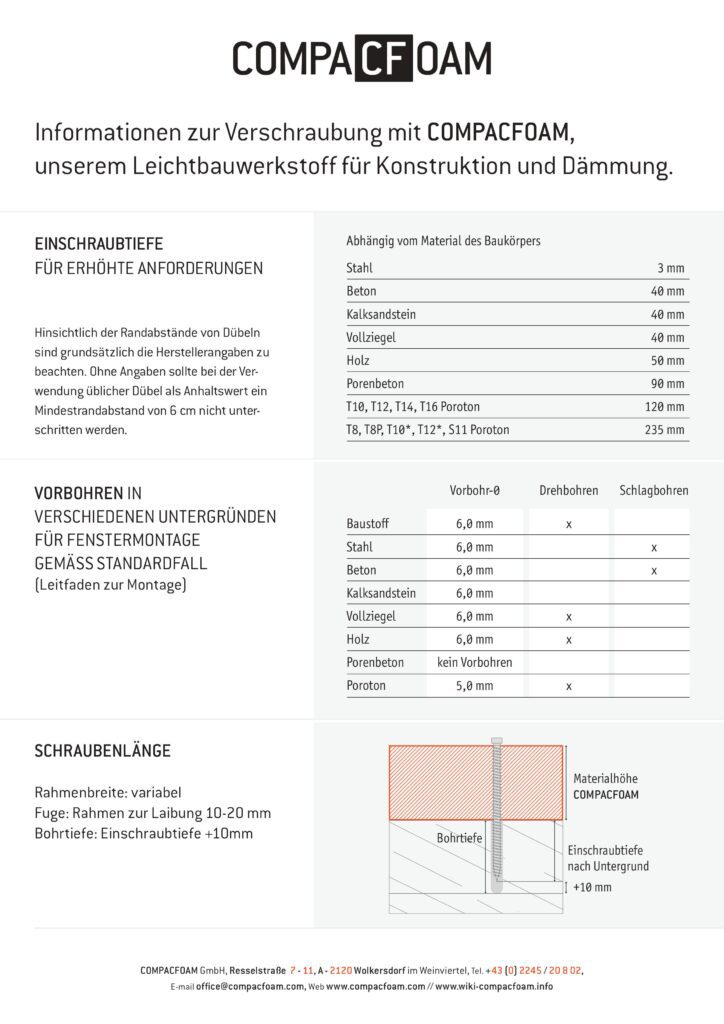

Technische Daten

CF 125

Dicken

60 mm

80 mm

U-Wert (W/ m2K)

0,68

0,51

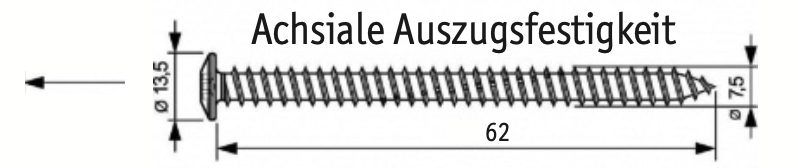

Schraubenauszug

Schraubenquerzug

825 N

439 N

Unterlegplatten in mm

max. Scheibengewicht in kg

60×40

381,80

53×66

556,00

53×140

1179,90

53×170

1432,78

53×210

1769,90

Brandklasse

DIN 4102-1 / EN 13501-1

B1/E

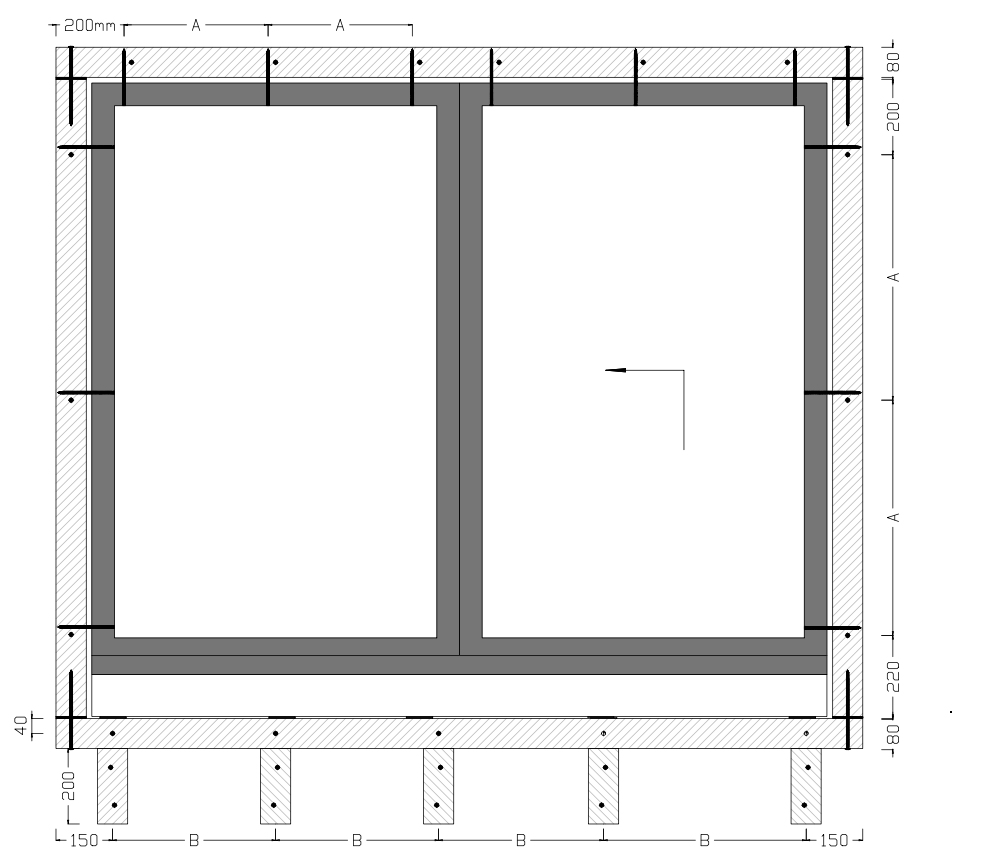

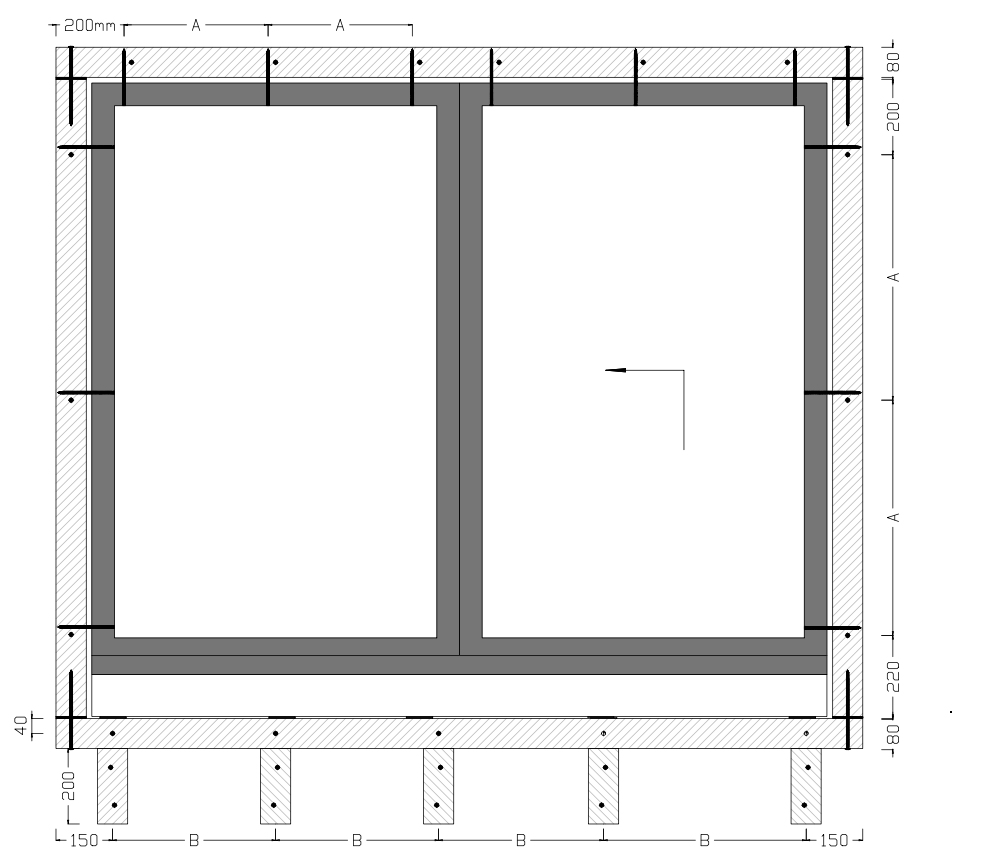

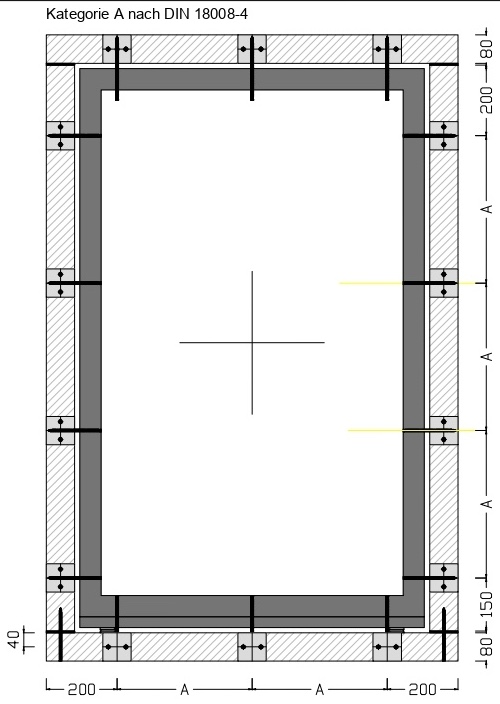

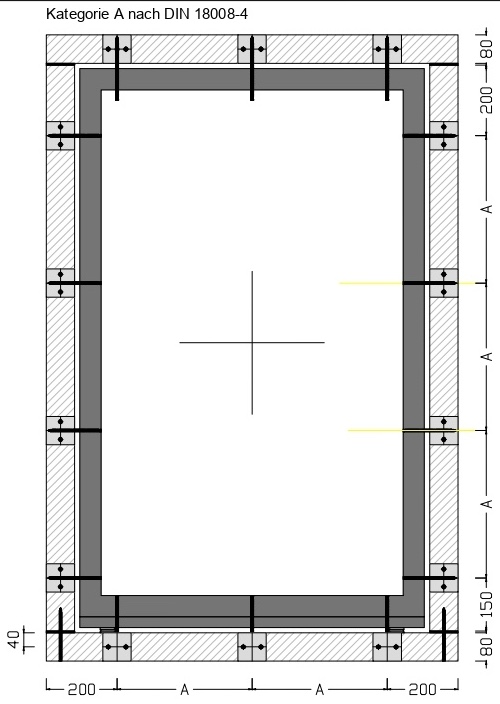

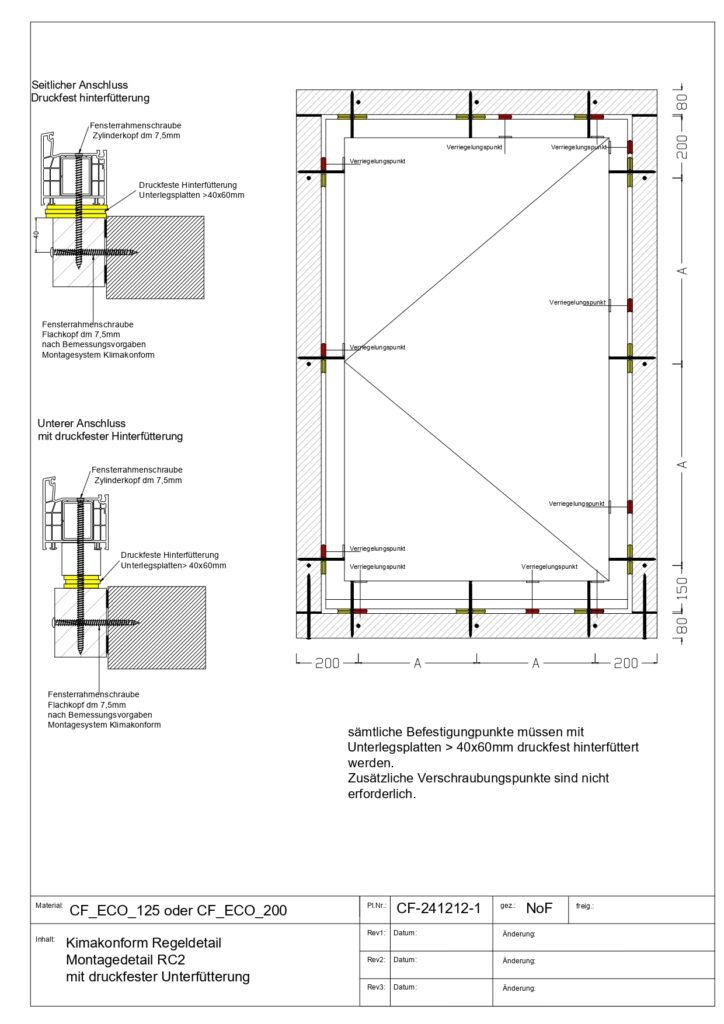

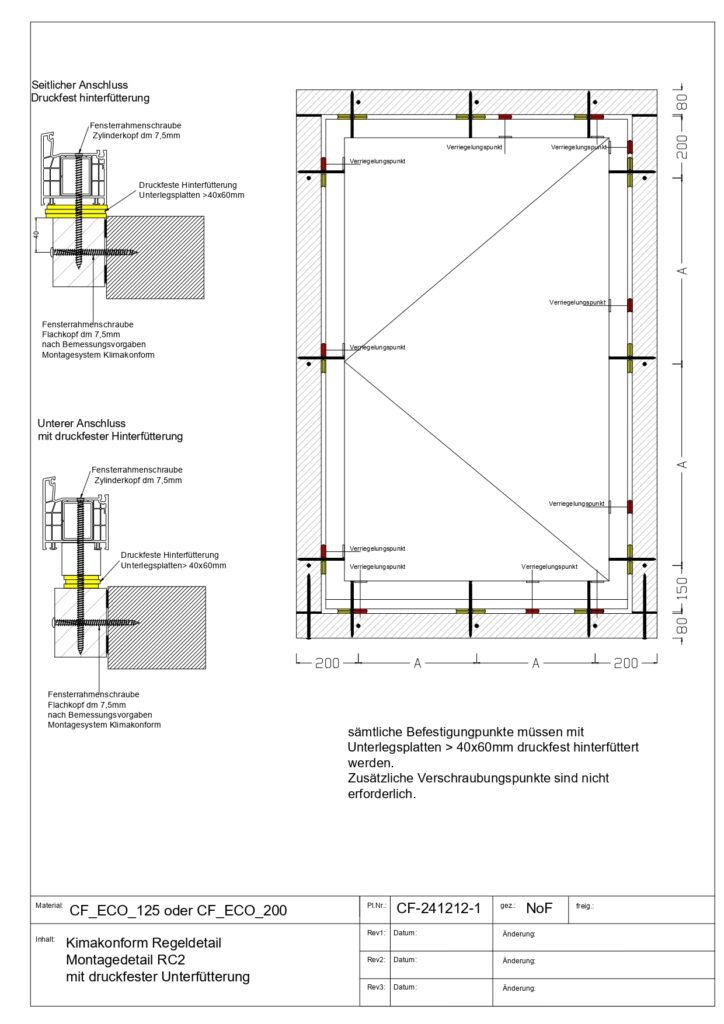

Technical drawings.

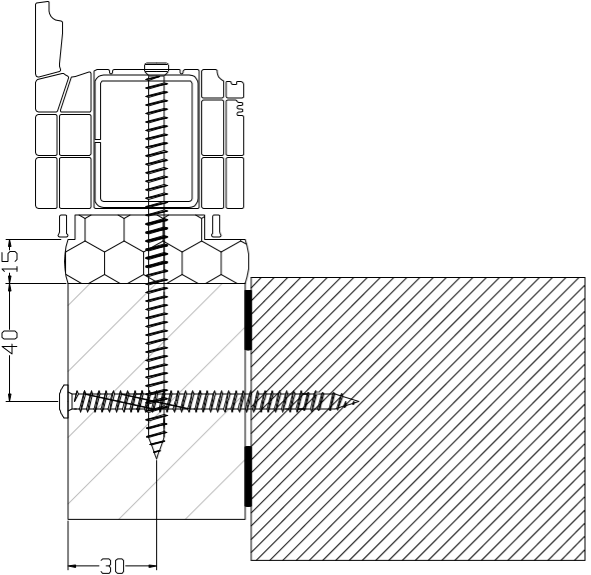

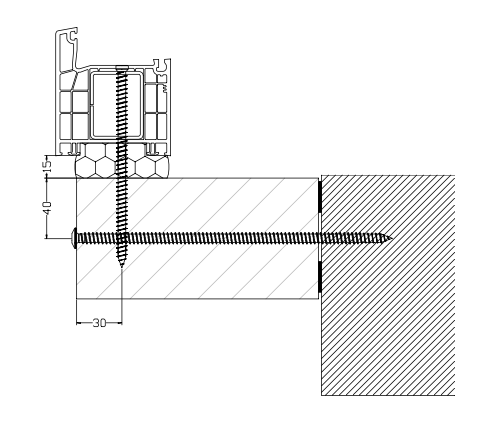

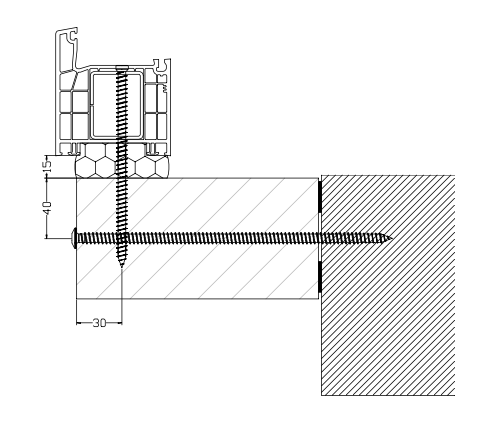

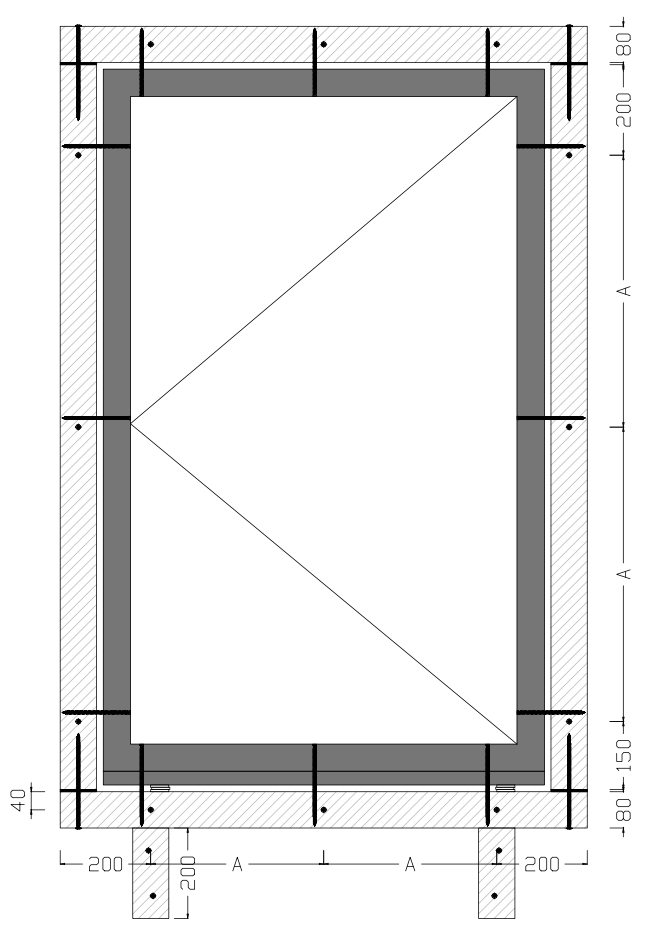

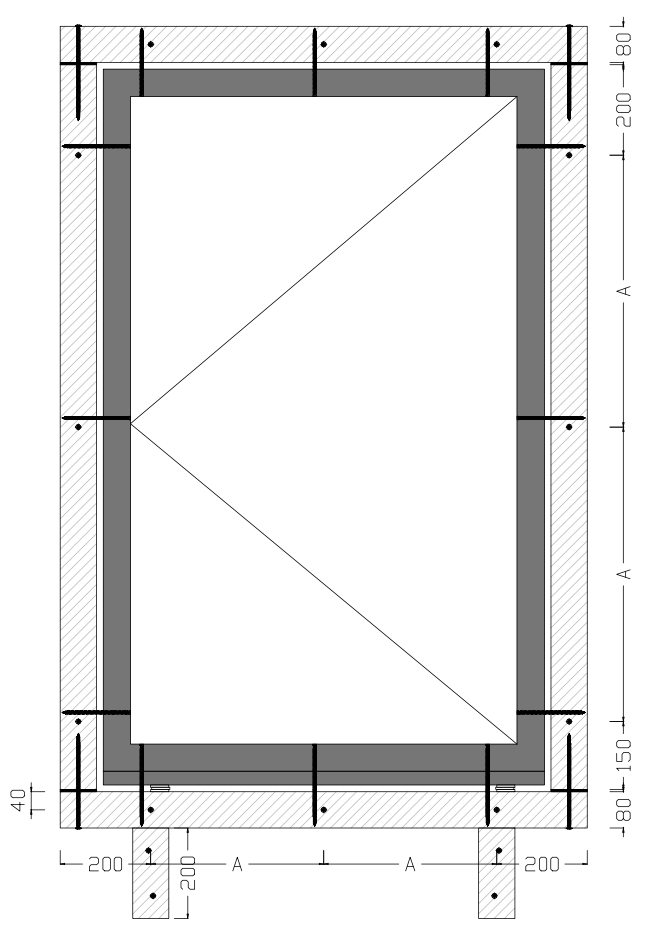

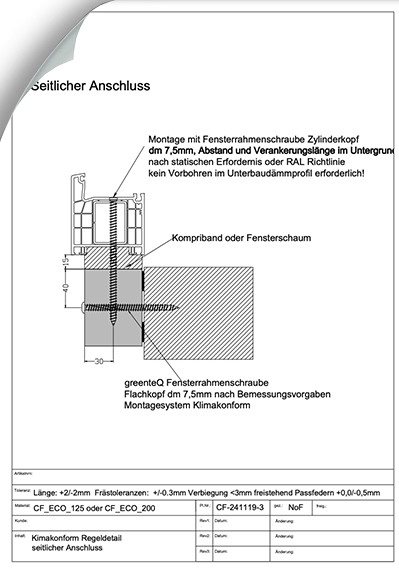

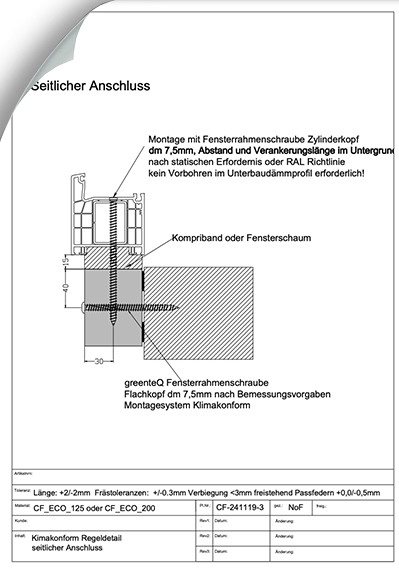

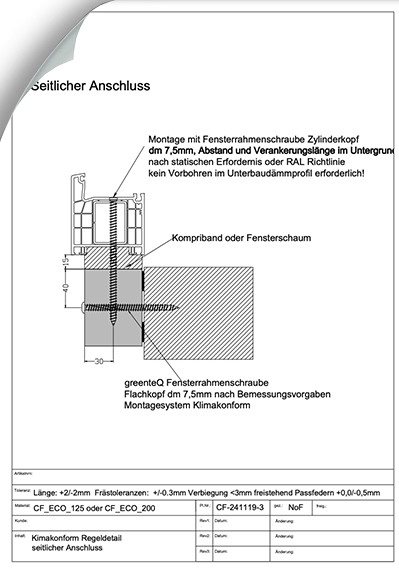

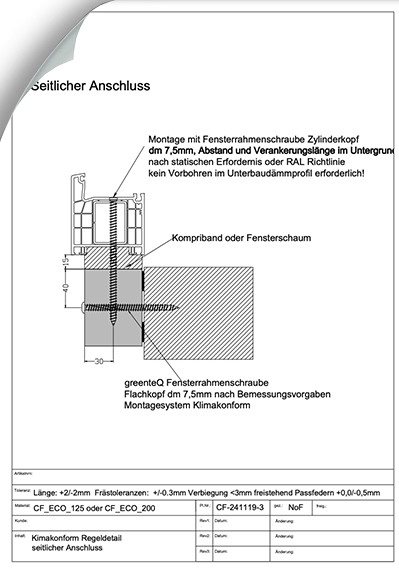

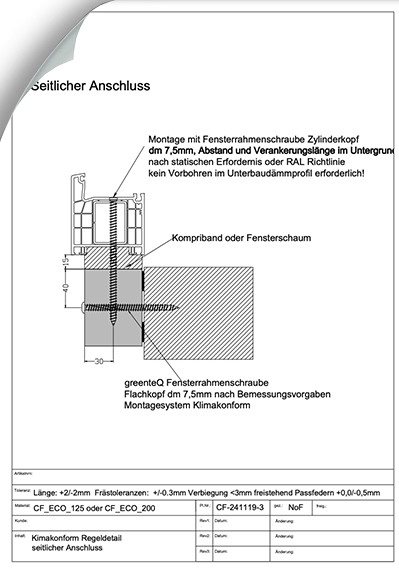

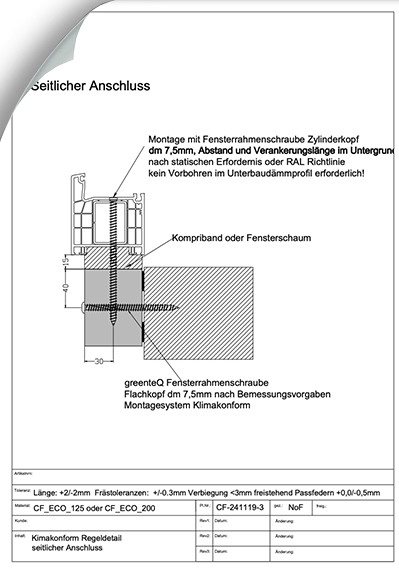

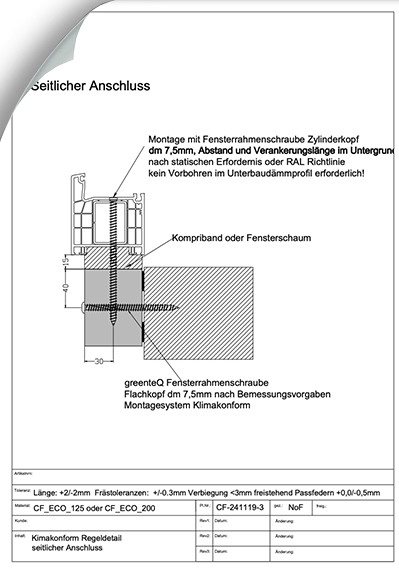

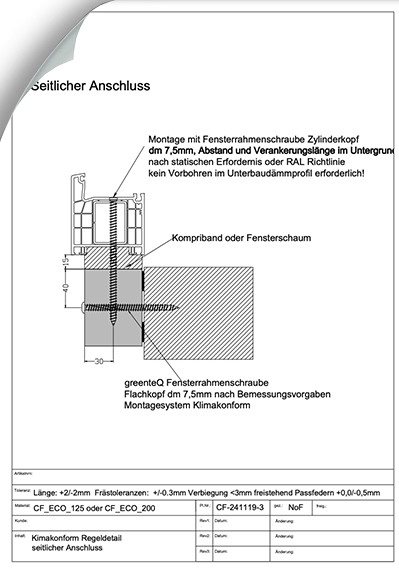

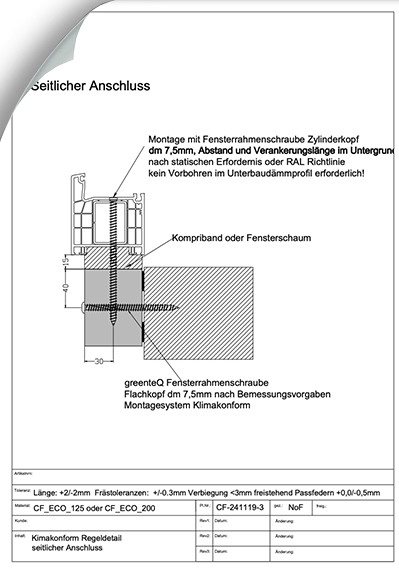

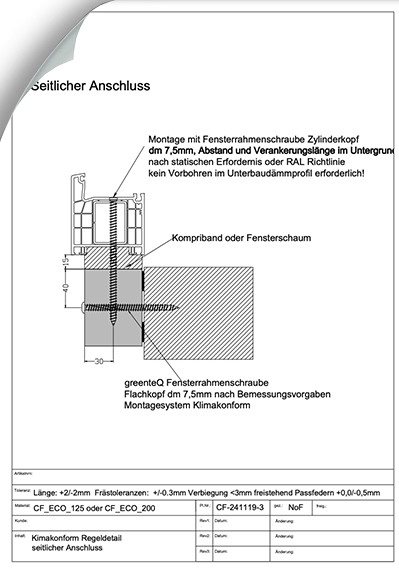

side connection

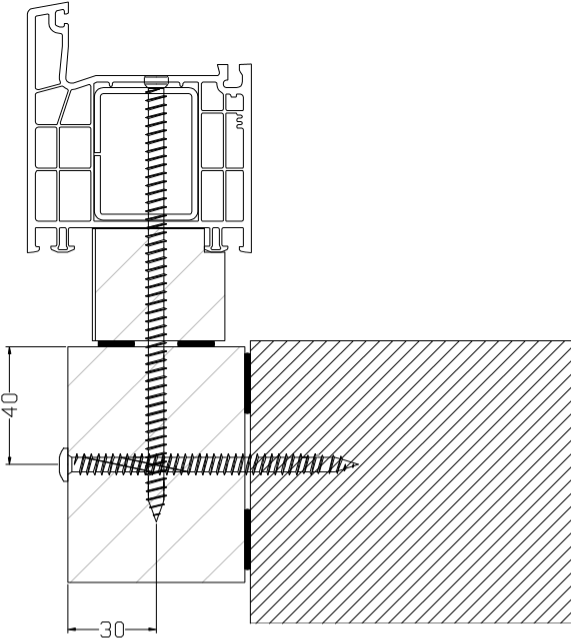

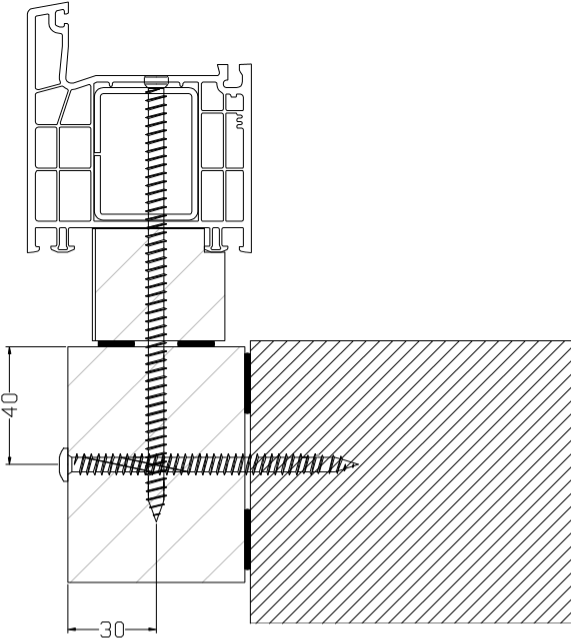

lower connection

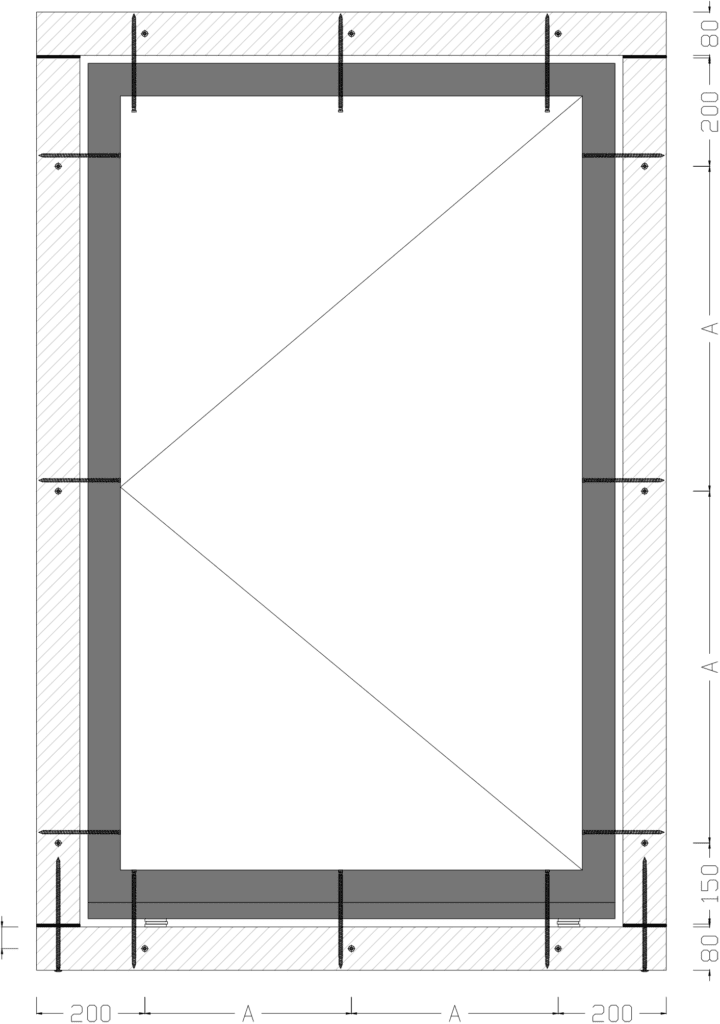

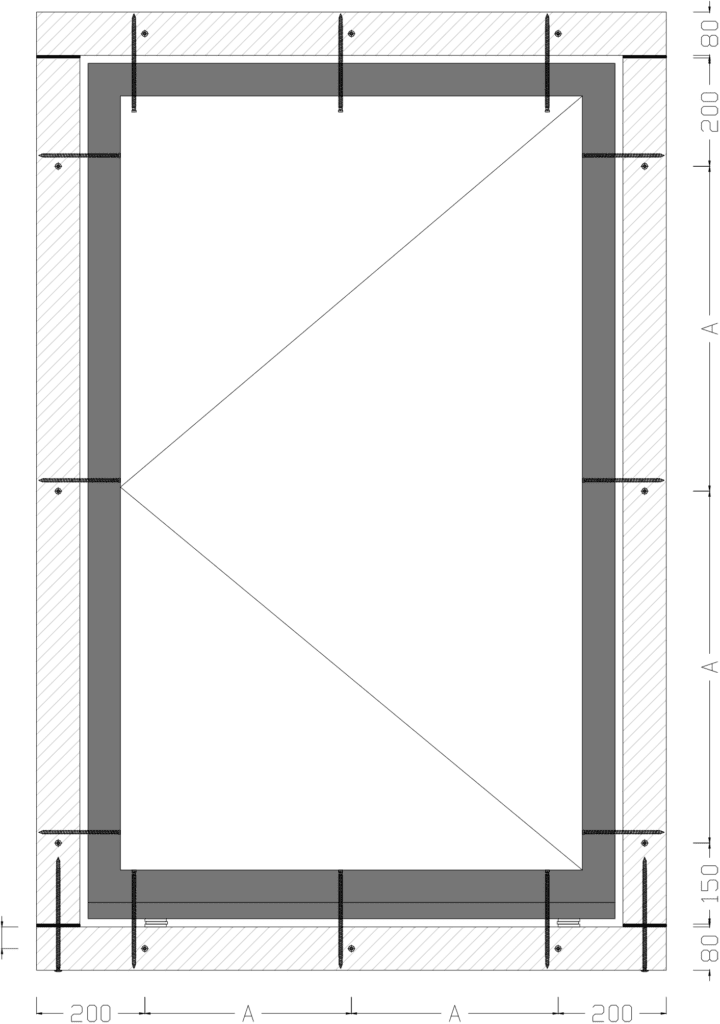

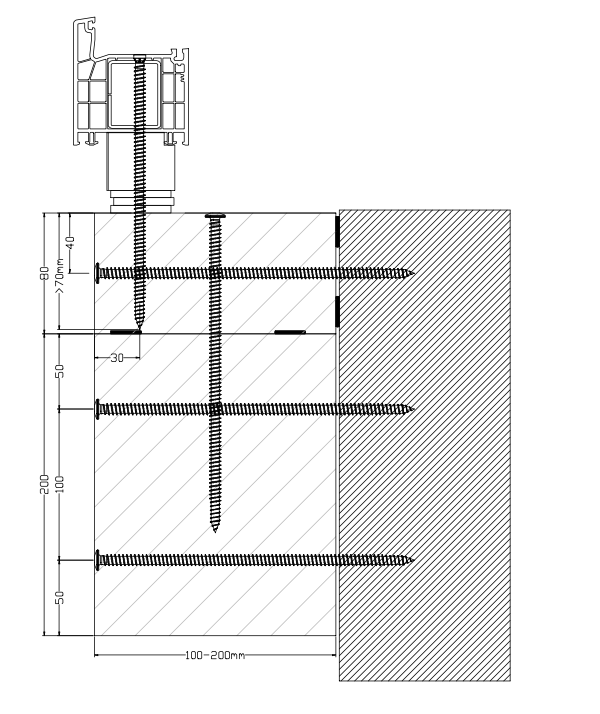

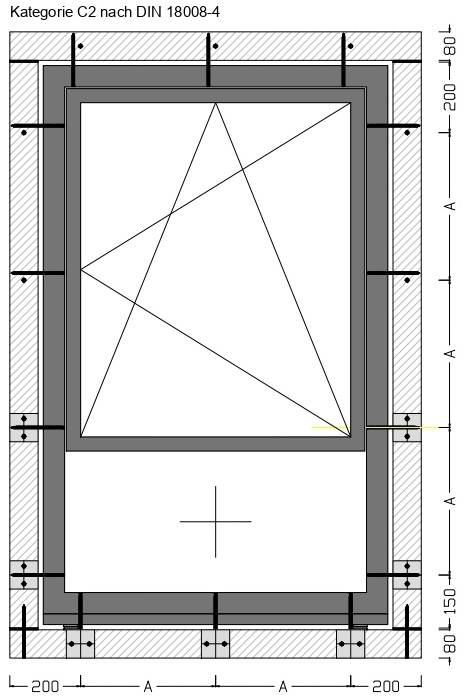

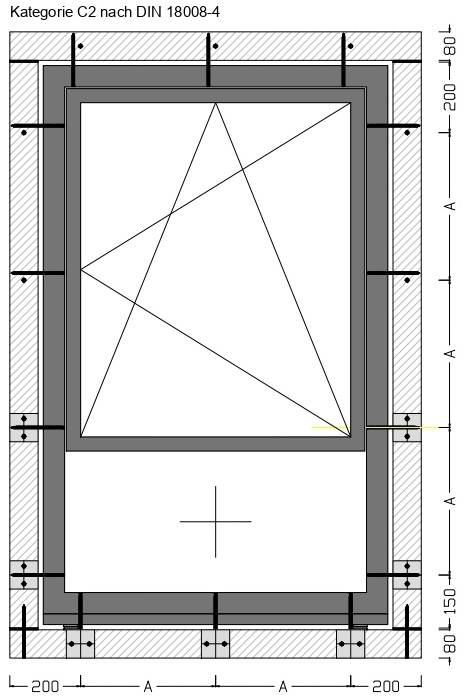

A….max. Screw distance <700mm

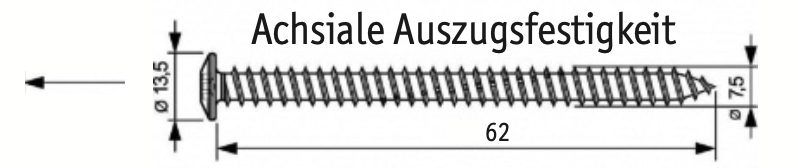

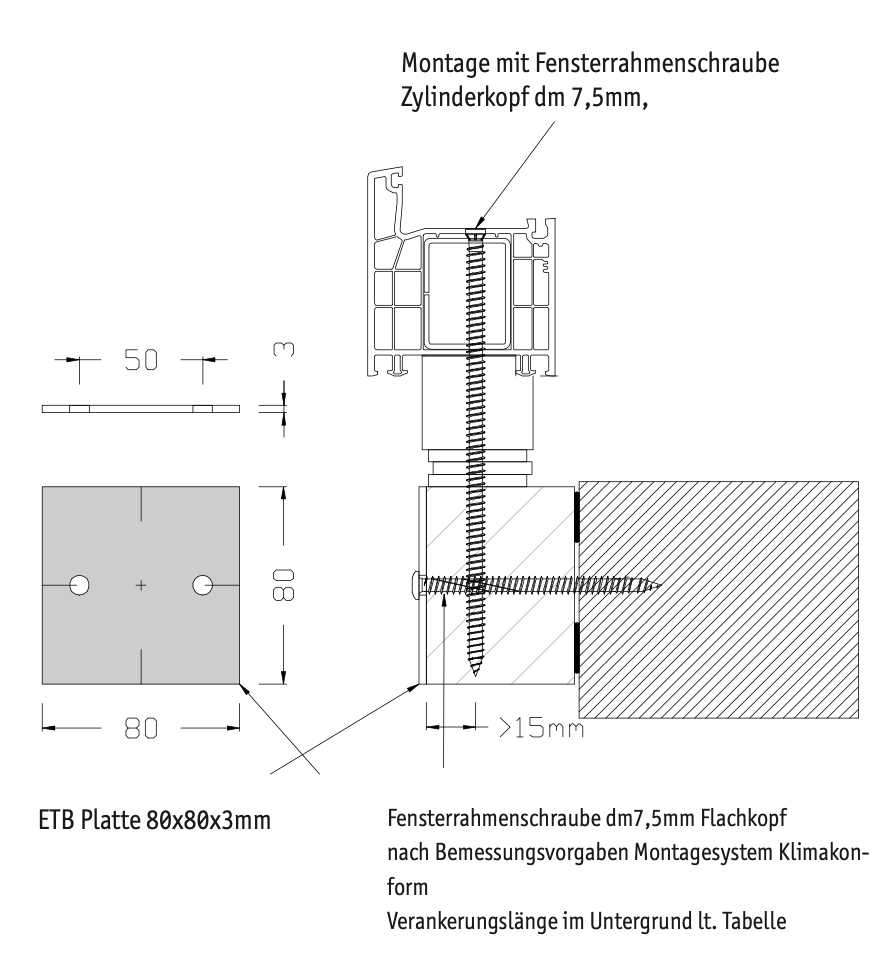

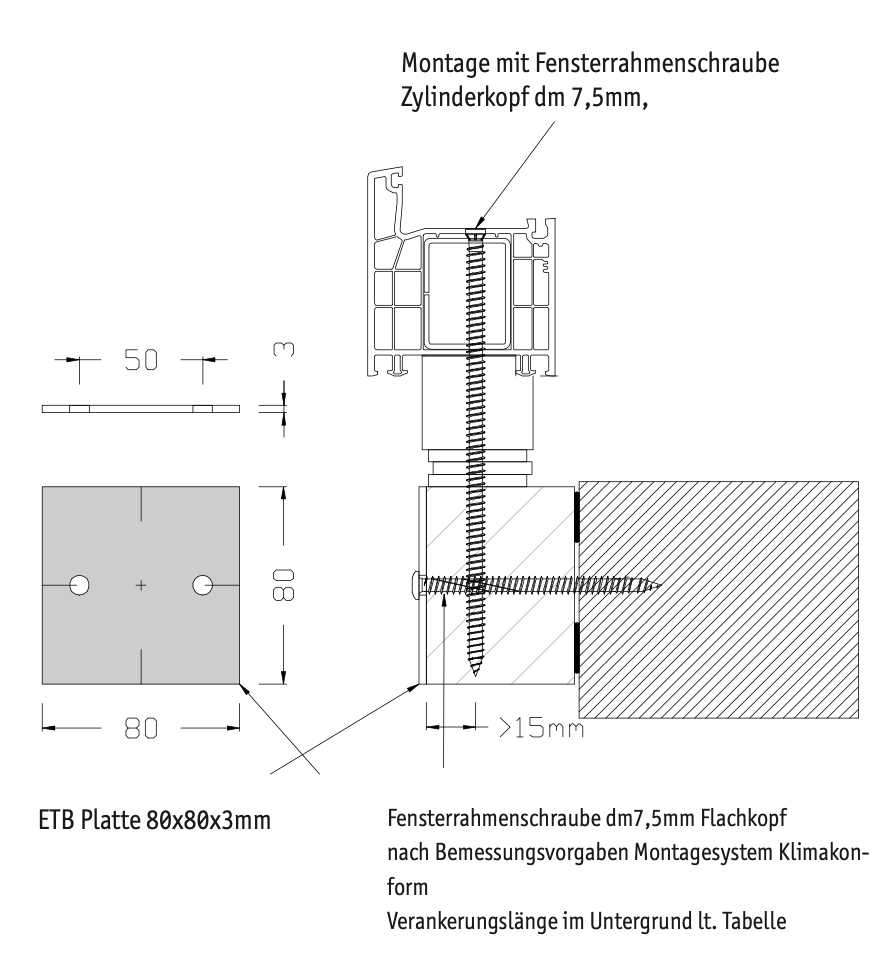

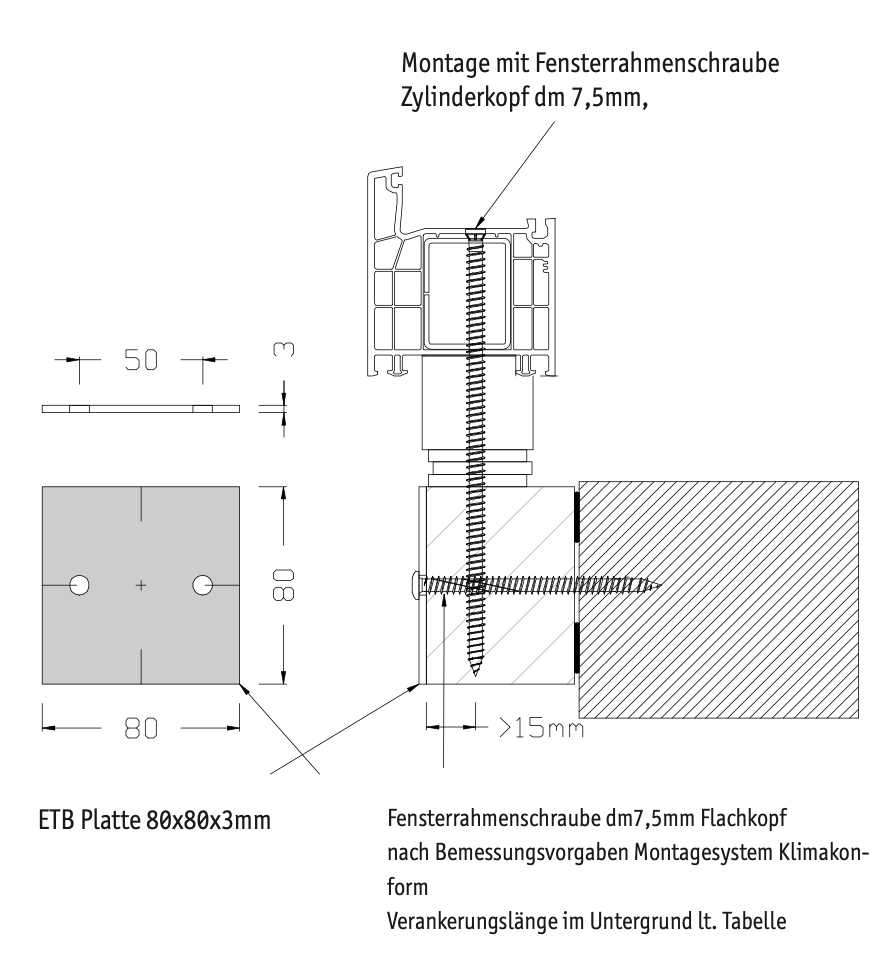

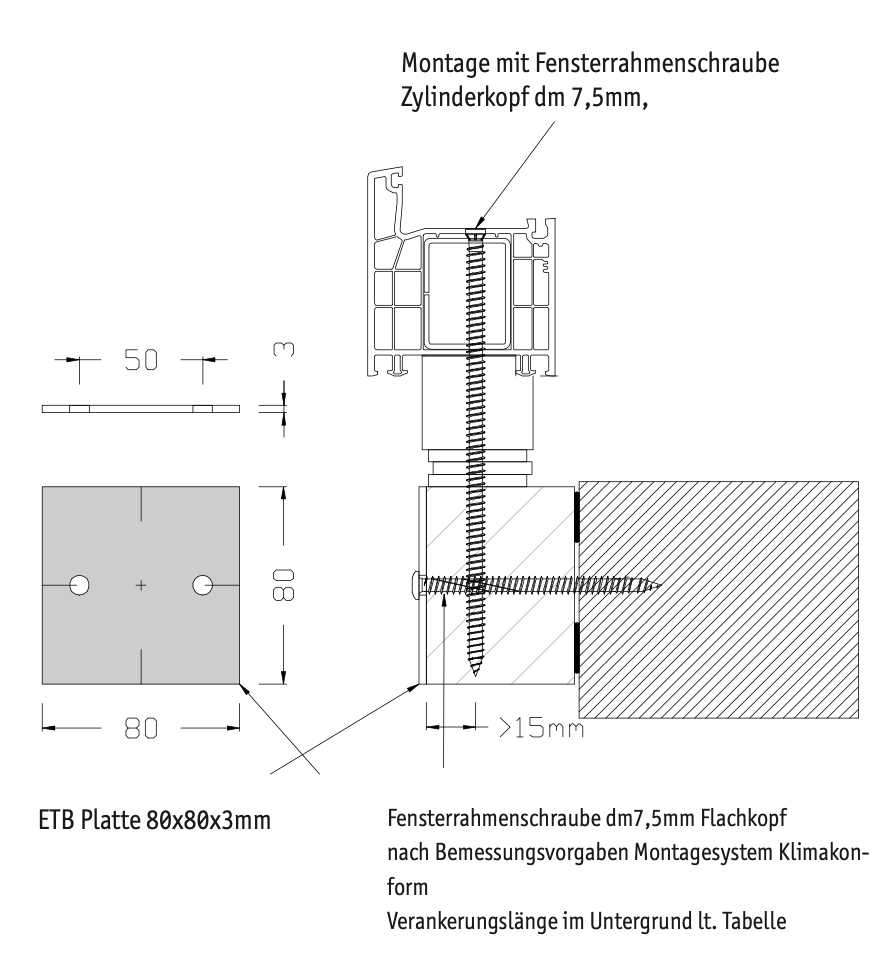

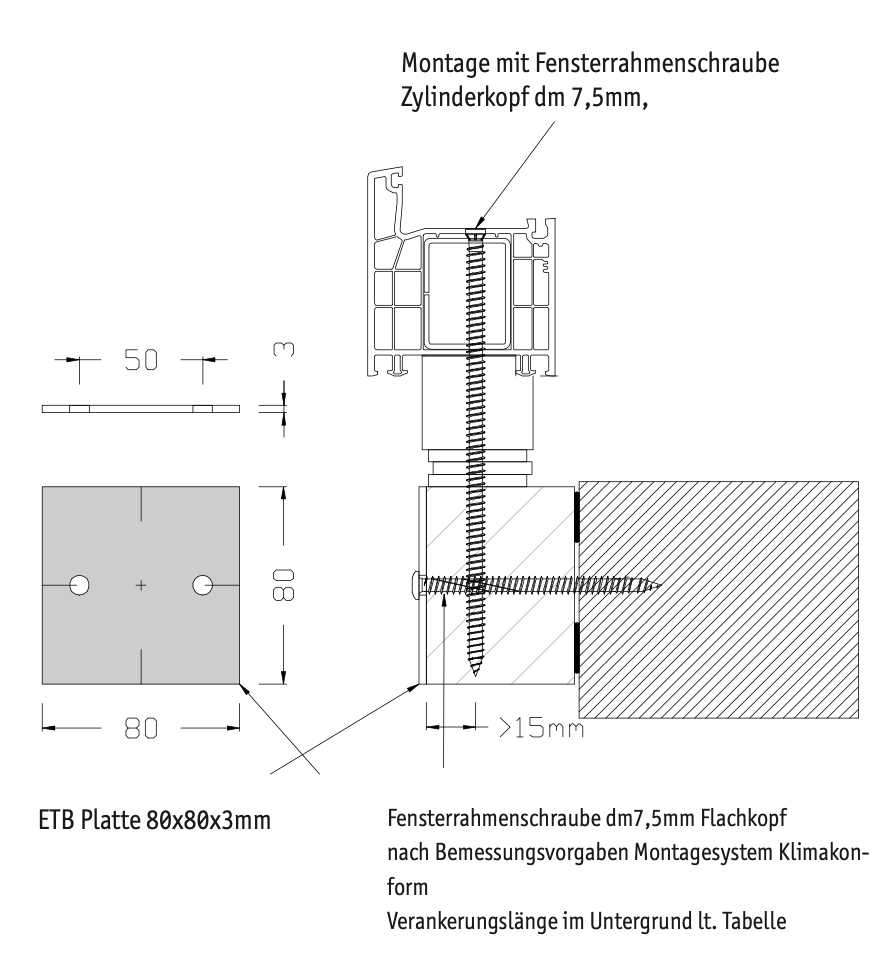

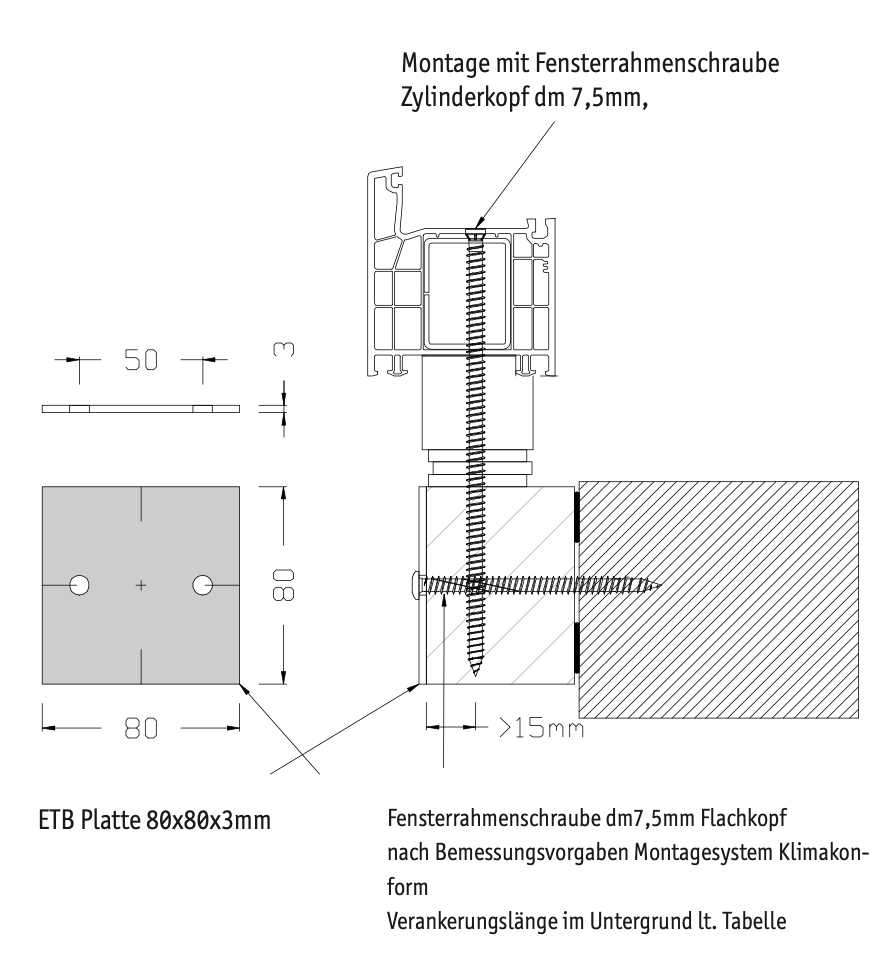

Window frame screw cylinder head

dm 7.5mm, distance and anchoring length in the substrate

According to static requirements or RAL guidelines, no pre-drilling in the substructure insulation profile is necessary!

Articlenr:

Toleranz:

Length: +2/-2mm Milling tolerances: +/-0.3mm Deflection <3mm free-standing keys +0.0/-0.5mm

Material:

CF_ECO_125 oder CF_ECO_200

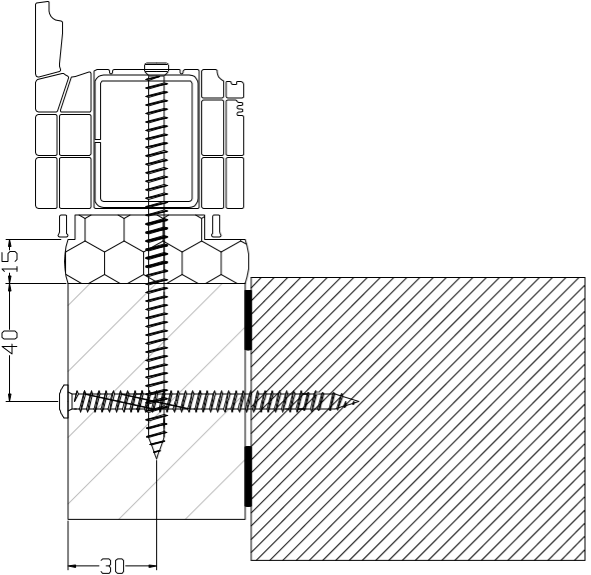

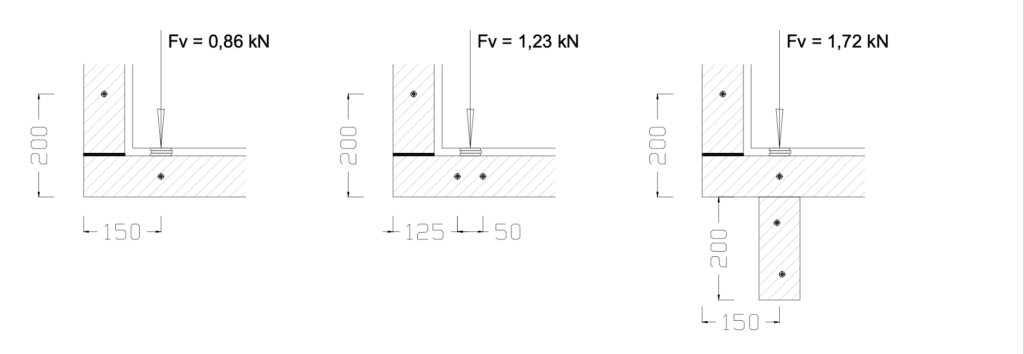

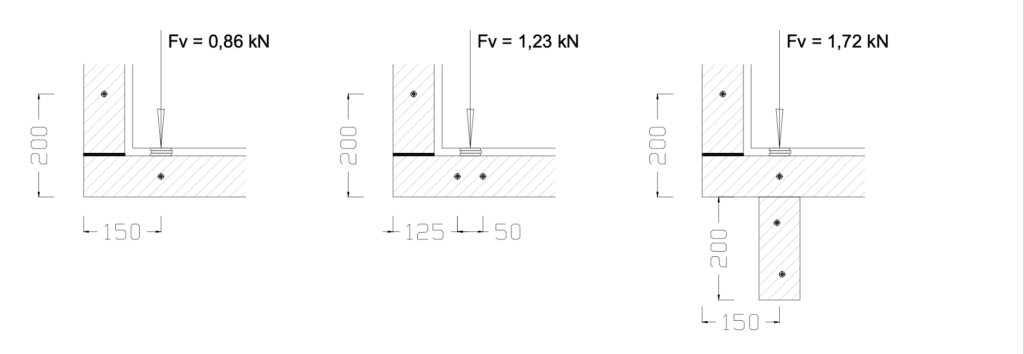

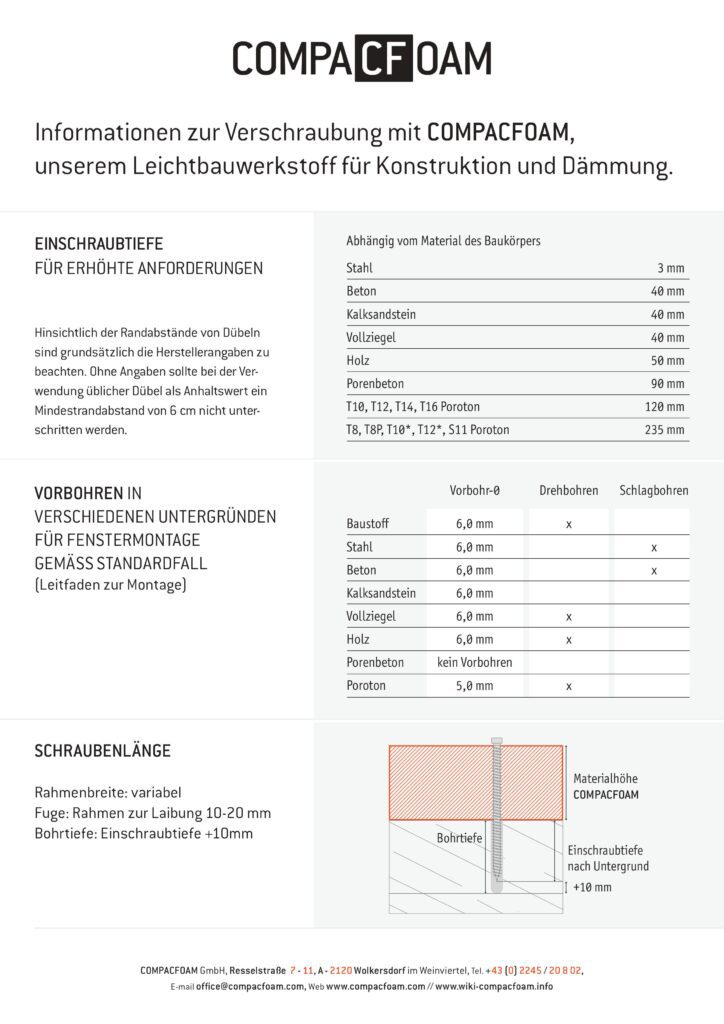

Dissipation of vertical loads:

Every window construction is supported by selective support blocks in the frame.

The entire dead load of the window is concentrated under these support points and must be safely transferred there into the wall.

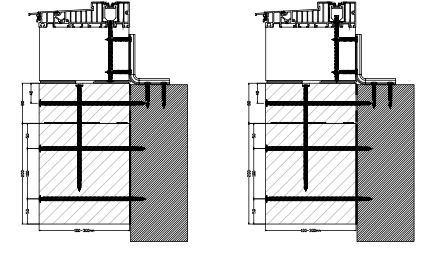

Version 1

Force per attachment point < 0.86 kN

Version 2

1 additional attachment point. Force per attachment point < 1.23 kN

Version 3

2 additional attachment points, force per attachment point < 1.72 kN

If the projection of the climate-compliant profile is > 100 mm, the console (version 3) must be installed. The individual support forces at the attachment points can be determined using the COMPACFOAM attachment calculator.

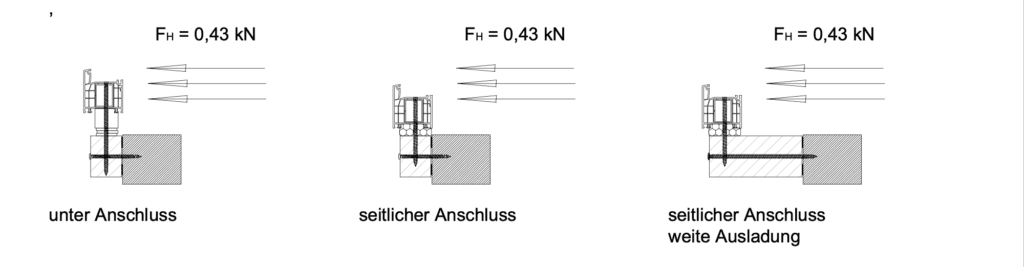

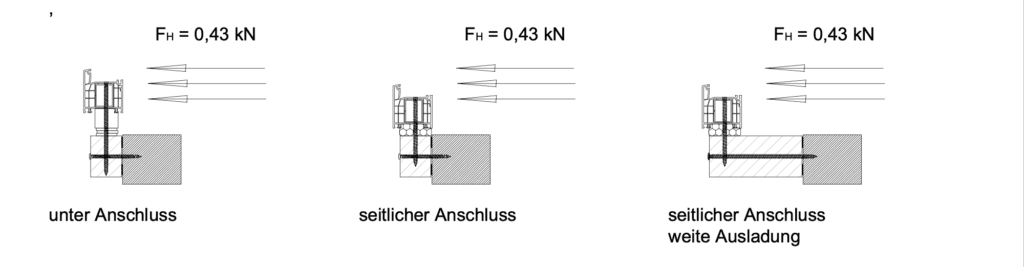

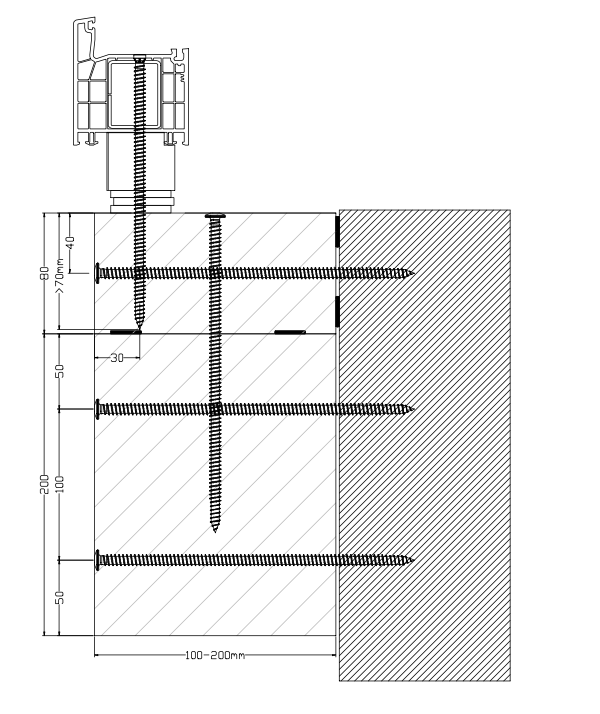

Dissipation of horizontal loads:

Horizontal loads in window structures arise due to wind or impact on the glazing panes. From there they are passed on to the frame construction. This load is transferred via the side screw connection

introduced into the assembly frame in a point-shaped manner.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

A….max. Screw distance at the top and sides <700mm or according to static requirements

B….max. Distance between supports at the bottom <500mm, arrangement under corner points of the fixed field, window frame screw, cylinder head dm 7.5mm, distance and anchoring length in the subsurface according to static requirements or RAL guidelines, no pre-drilling in the substructure insulation profile required!

lower connection

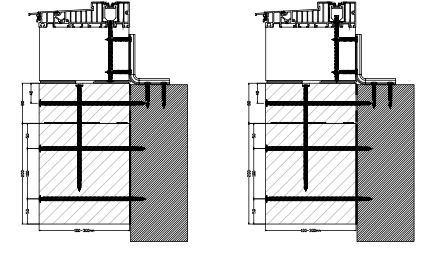

Screw connection from below:

lower connection

Screw connection from above:

side connection

lower connection

A….max. Verschraubungsabstand <700mm

Fensterrahmenschraube Zylinderkopf

dm 7,5mm, Abstand und Verankerungslänge im Untergrund

nach statischen Erfordernis oder RAL Richtlinie kein Vorbohren im Unterbaudämmprofil erforderlich!

Artikelnr:

Toleranz:

Länge: +2/-2mm Frästoleranzen: +/-0.3mm Verbiegung <3mm freistehend Passfedern +0,0/-0,5mm

Material:

CF_ECO_125 oder CF_ECO_200

Montageanleitung

2. Applying glue

3. Pre-drilling and screwing

4. Positioning and alignment

Diversity of the climate conform system

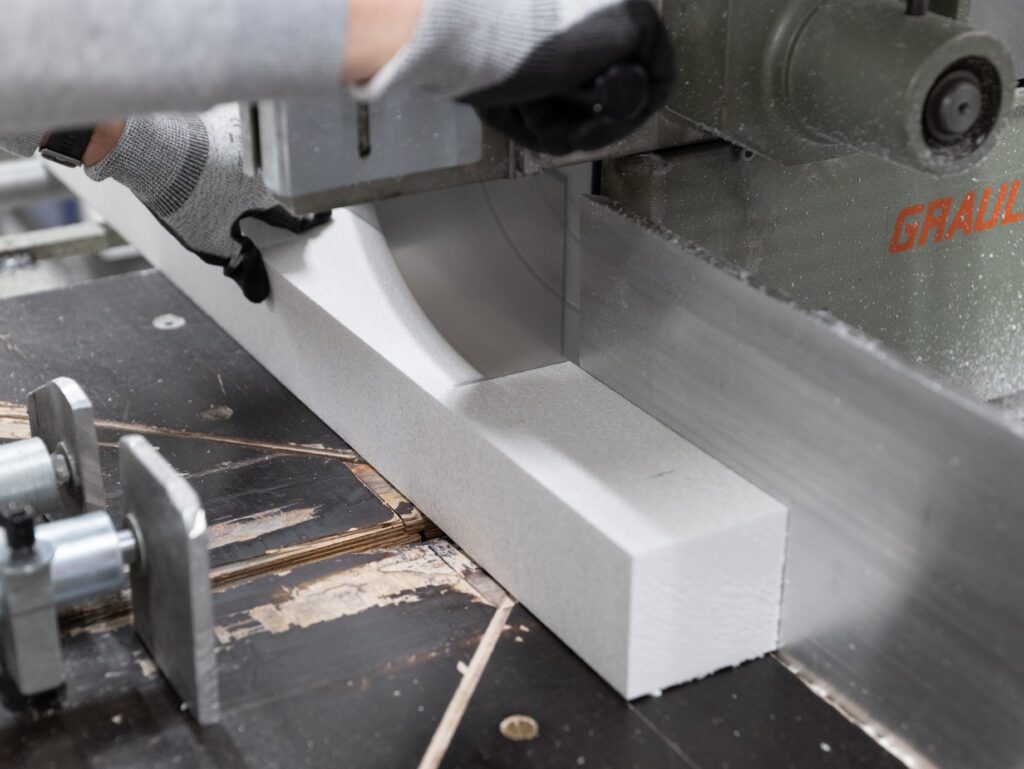

The climate-compliant system offers tailor-made special solutions for demanding construction projects. Whether flexible cross-sections, special shapes, integrated insulation wedges or individual soffit solutions – almost every requirement can be implemented. Specially manufactured sloping profiles in the upper area also offer optimal protection from rainwater during the construction phase.

Precise manufacturing is guaranteed by the most modern technologies:

The products are free of distortion and bending, which guarantees excellent stability. Thanks to the low weight and high strength, installation is quick and easy.

This variety of options ensures perfect adaptation to every project and sets new standards in functionality, efficiency and quality.

Photo as a placeholder, the original is in progress.

Drill the lower bar 150 mm from the end of the bar and place the following holes at a distance of 700 mm each.

Use MS polymer for corner and joint bonding to create airtight and driving rain-tight connections.

COMPACFOAM can be easily cut to size using standard saws such as circular saws, pressure beam saws or hand-held circular saws. It is important to use saw blades with large tooth spacing and free chip space.

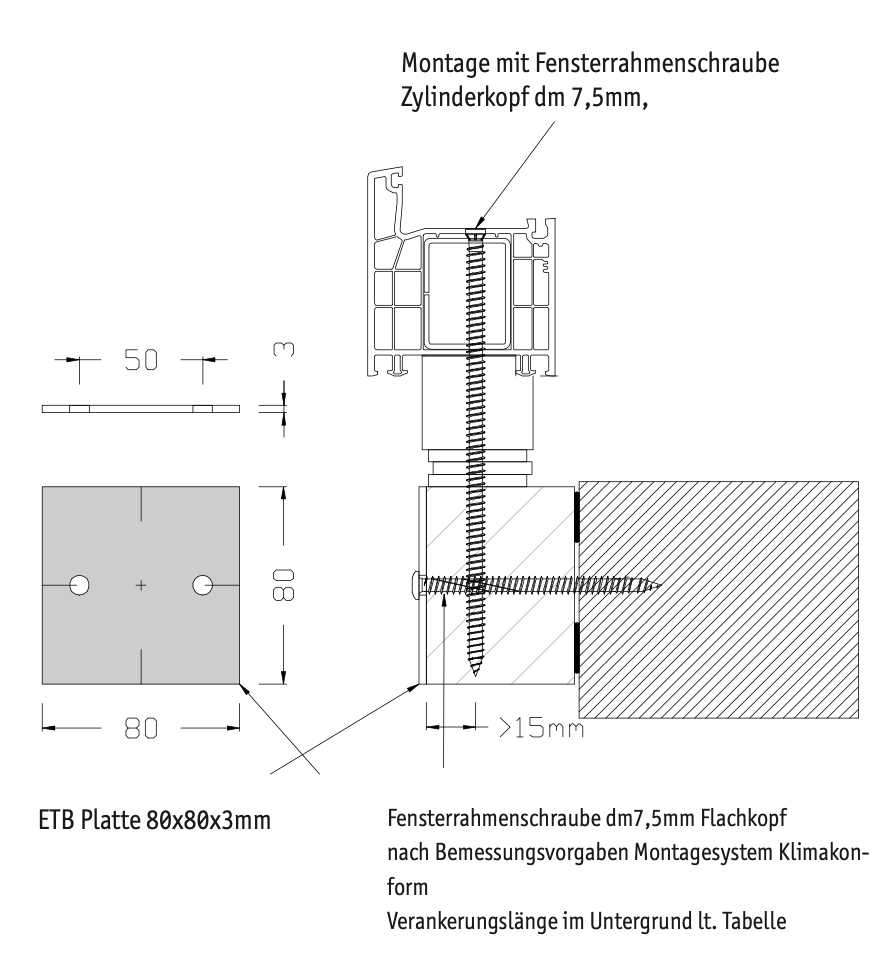

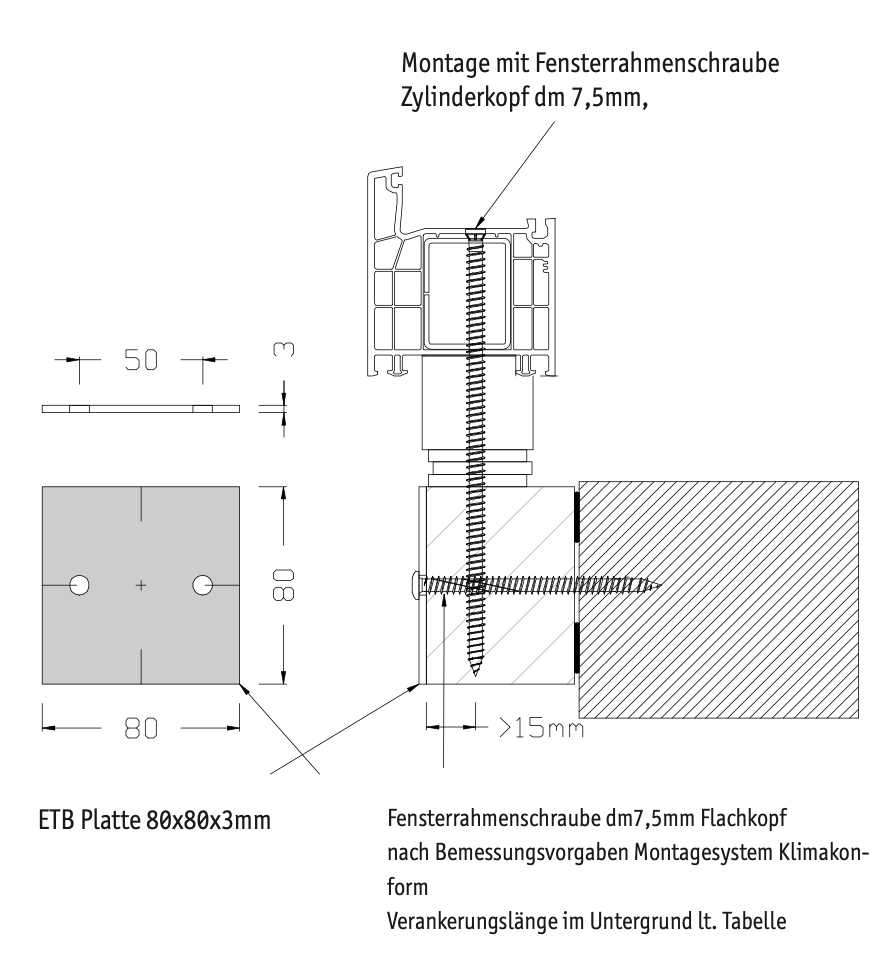

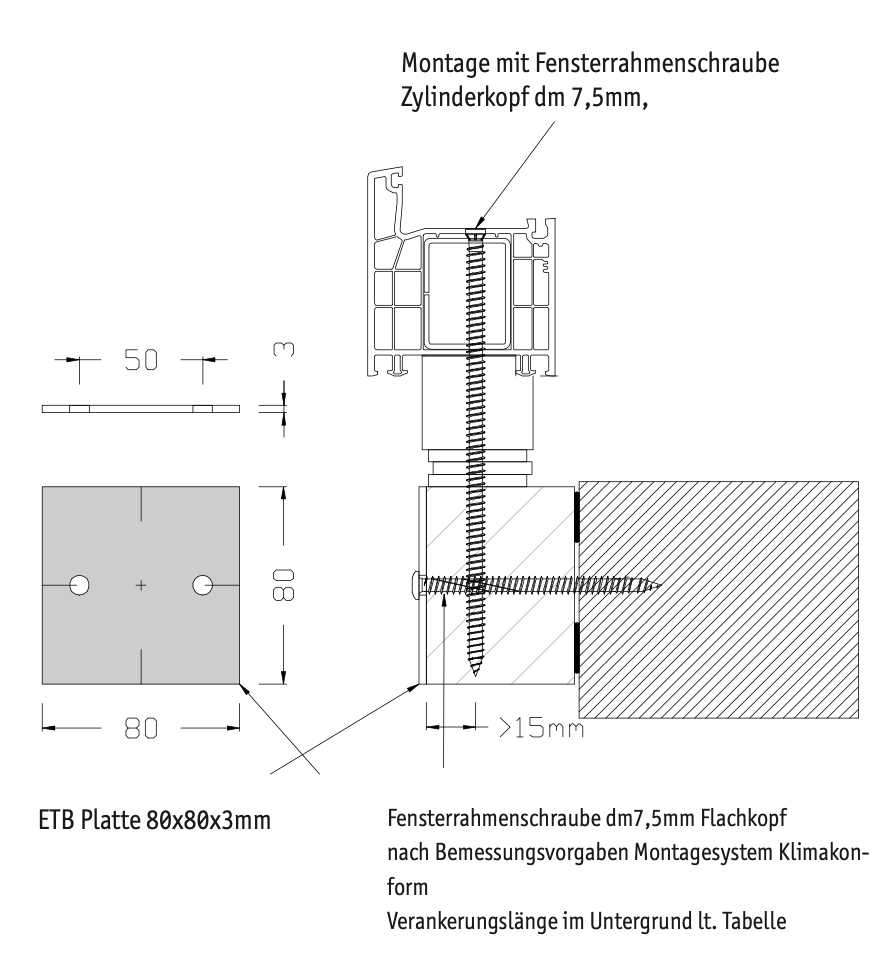

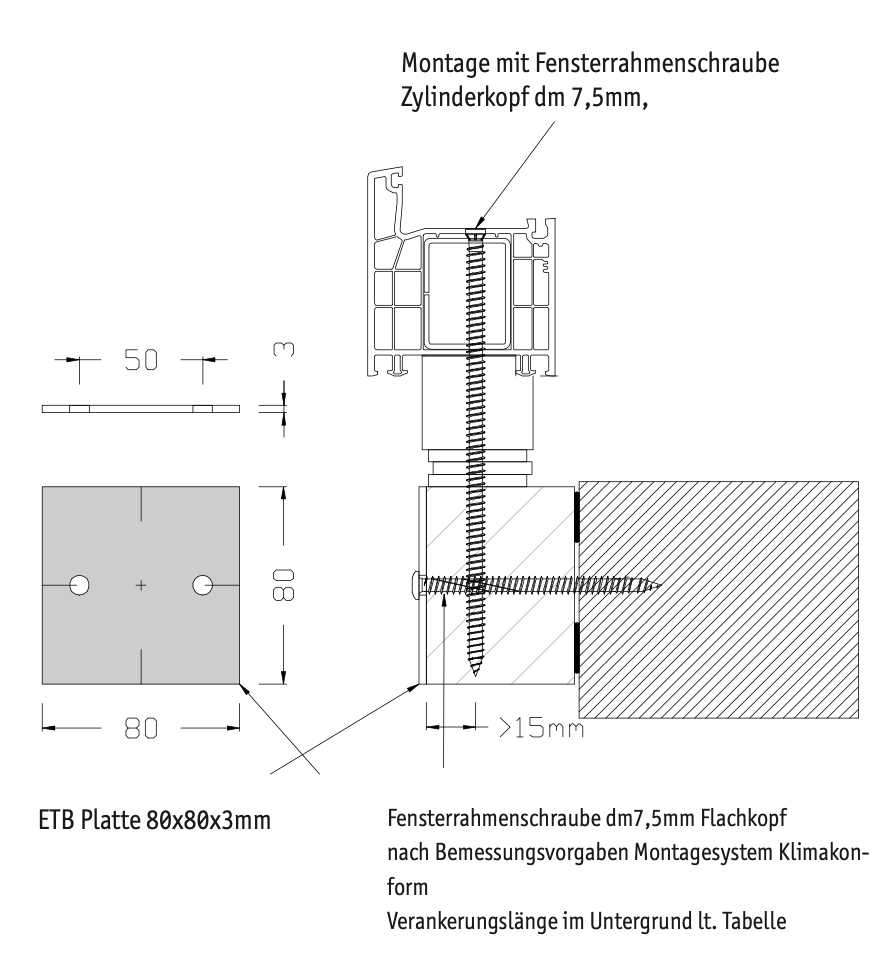

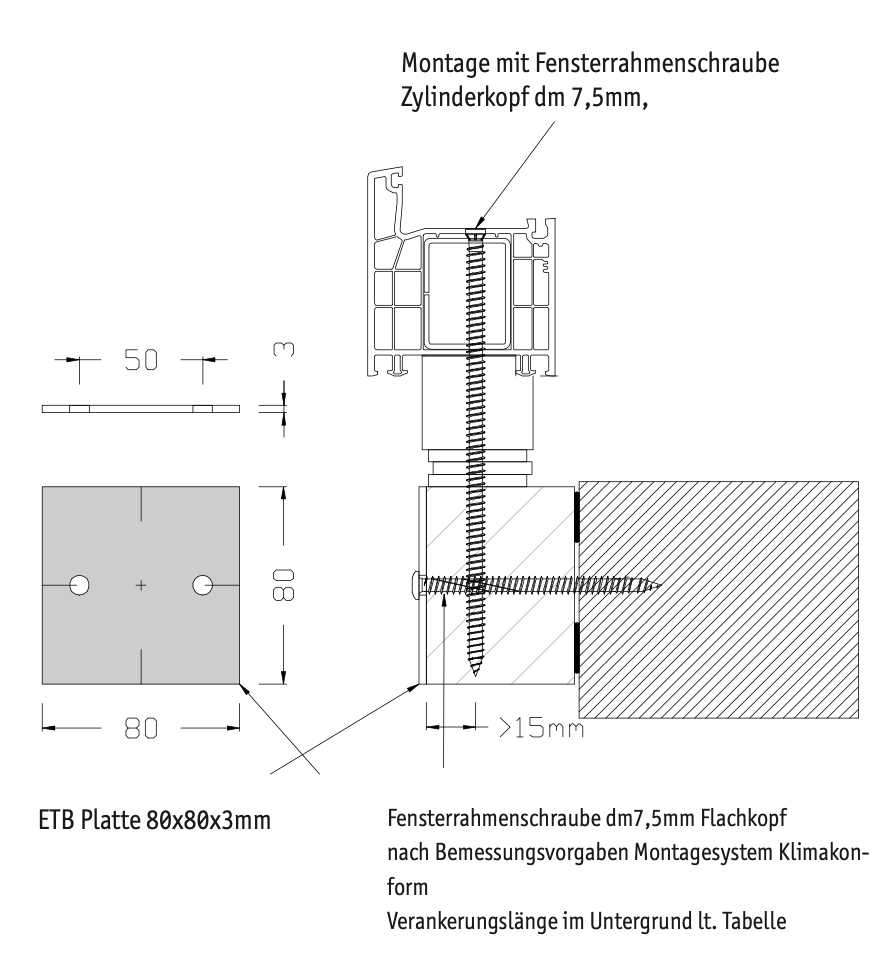

The ETB guidelines for fall-proof floor-to-ceiling components require a load bearing of at least 2.8 kN at the relevant attachment points. Fall-protecting glazing is used to protect people from falling to a lower level. They should offer a low risk of injury in the event of a collision and ensure that the traffic area below is not endangered by broken glass. Examples of such glazing include parapets, glass stair railings and floor-to-ceiling windows.

The climate-compliant system meets all of these requirements and therefore offers the highest level of protection and safety for fall-proof elements.

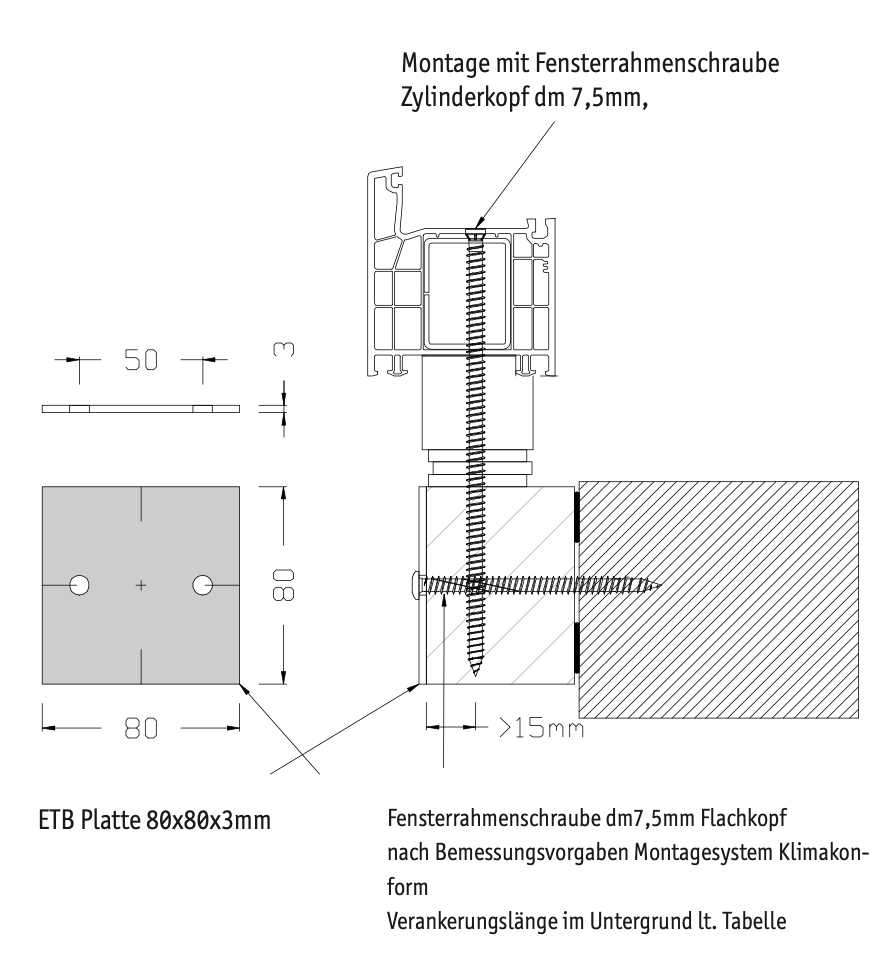

Fastening elements with fall protection properties (ETB)

For elements with fall protection properties (ETB), depending on the category (A/C2/C3), an additional system ETB plate must be included

Climate Compliant can be fastened from the Climate Compliant profile to the subsurface (mural) using additional screws. Fixing distance A: Plastic windows max. 700 mm, wooden, wooden aluminum and aluminum windows max. 700 mm.

Fastening elements with fall protection properties (ETB)

For elements with fall protection properties (ETB), depending on the category (A/C2/C3), an additional system ETB plate must be included

Climate Compliant can be fastened from the Climate Compliant profile to the subsurface (mural) using additional screws. Fixing distance A: Plastic windows max. 700 mm, wooden, wooden aluminum and aluminum windows max. 700 mm.

Fastening elements with fall protection properties (ETB)

For elements with fall protection properties (ETB), depending on the category (A/C2/C3), an additional system ETB plate must be included

Climate Compliant can be fastened from the Climate Compliant profile to the subsurface (mural) using additional screws. Fixing distance A: Plastic windows max. 700 mm, wooden, wooden aluminum and aluminum windows max. 700 mm.

The burglary protection test is carried out in accordance with the DIN EN 1627-1630 standard and includes the following requirements:

The climate-compliant system meets all of these requirements and therefore offers the highest level of protection and safety for every construction project.

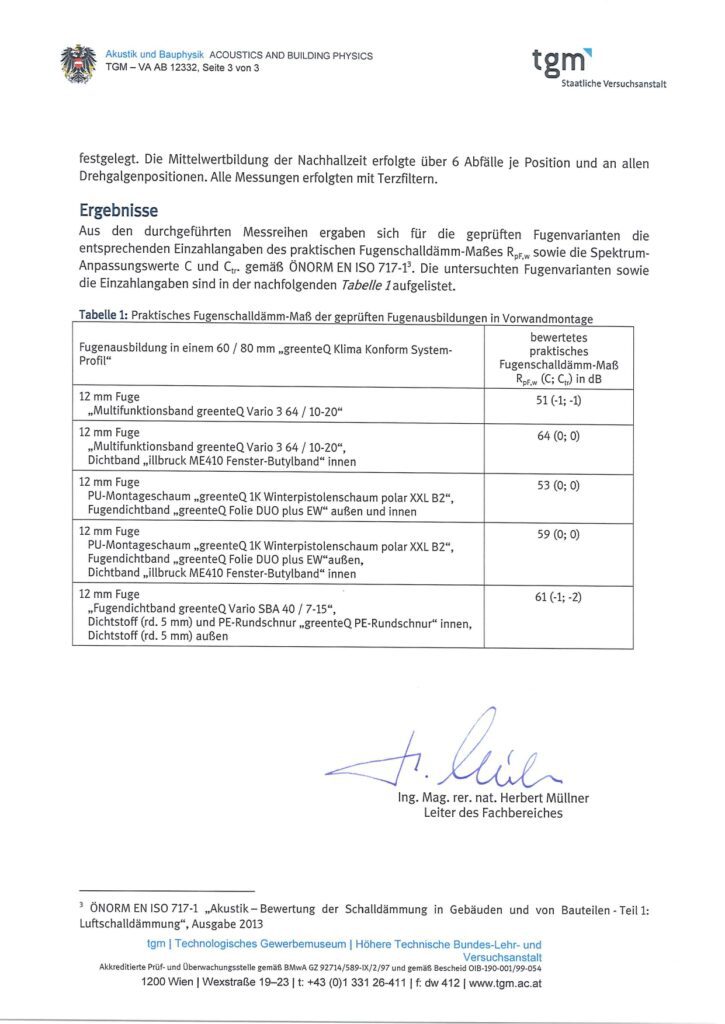

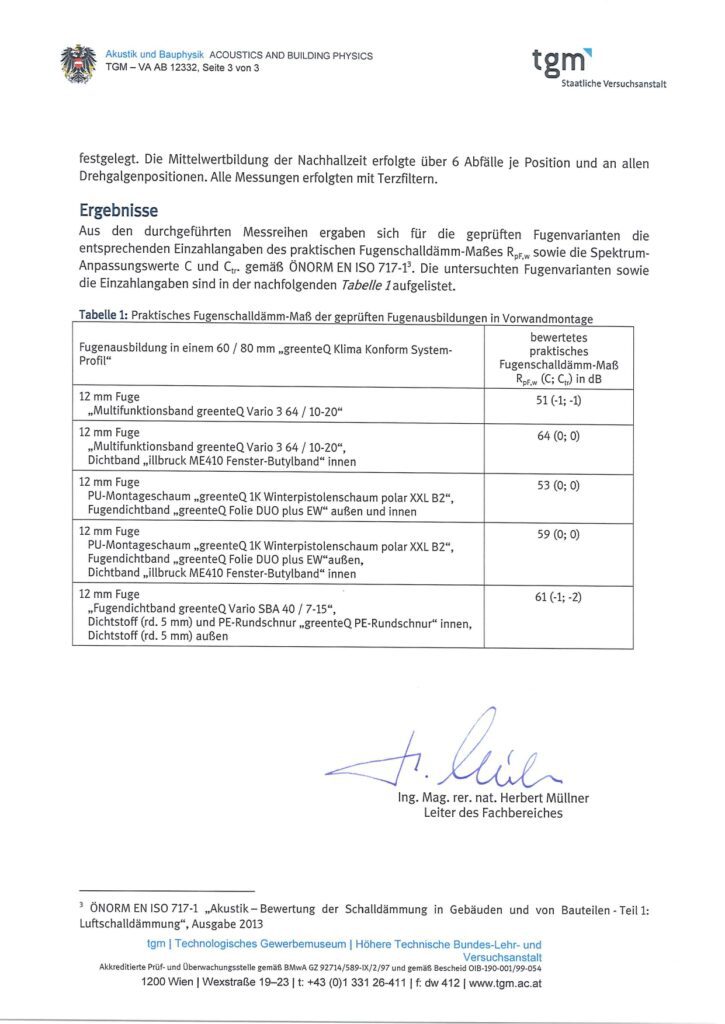

Sound insulation – climate friendly

When installing in front of a wall, sound insulation plays a central role, especially in areas such as window construction, facade construction or metal construction. Through the targeted use of innovative materials and techniques, sound bridges can be minimized and optimal acoustic properties for the building can be ensured.

Joint formation in a 60/80

Climate compliant system

Rated practical

Joint sound insulation measure

Rpf,w (C; Ctr) in dB

12mm joint

Multifunctional band 10-20mm

51 (-1; -1)

12mm joint

Multifunctional band 10-20mm

Butyl sealing tape inside.

64 (-1; -1)

12mm joint

Multifunctional tape 10-20mm

Butyl sealing tape inside.

53 (-1; -1)

12mm joint

Multifunctional band 7-15mm middle

Sealant (5mm) and round cord inside and outside

59 (-1; -1)

Thermal protection: fRsi value in front of wall installation

Climate compliant

Mold formation often results from temperatures on the inner reveal surface that are too low. DIN 4108-2 defines the temperature factor fRsi, which describes the relationship between the surface temperature and the inside and outside temperatures. A value of at least 0.7 ensures that the temperature remains high enough to prevent mold from forming.

In a standard climate (+20 °C inside, 50% humidity, -5 °C outside) the critical surface temperature is +12.6 °C, which corresponds to a risk of mold less than 80% relative humidity.

Advantages of climate compliant installation

The Klima Konform pre-wall mounting system improves the temperature gradients between the wall system and the window. The isotherms clearly show the advantages of pre-wall installation compared to conventional installation.

With Climate Compliant, optimal thermal protection is achieved that meets the FRSI requirements and prevents mold formation

Framework conditions

Color markings of the isotherms:

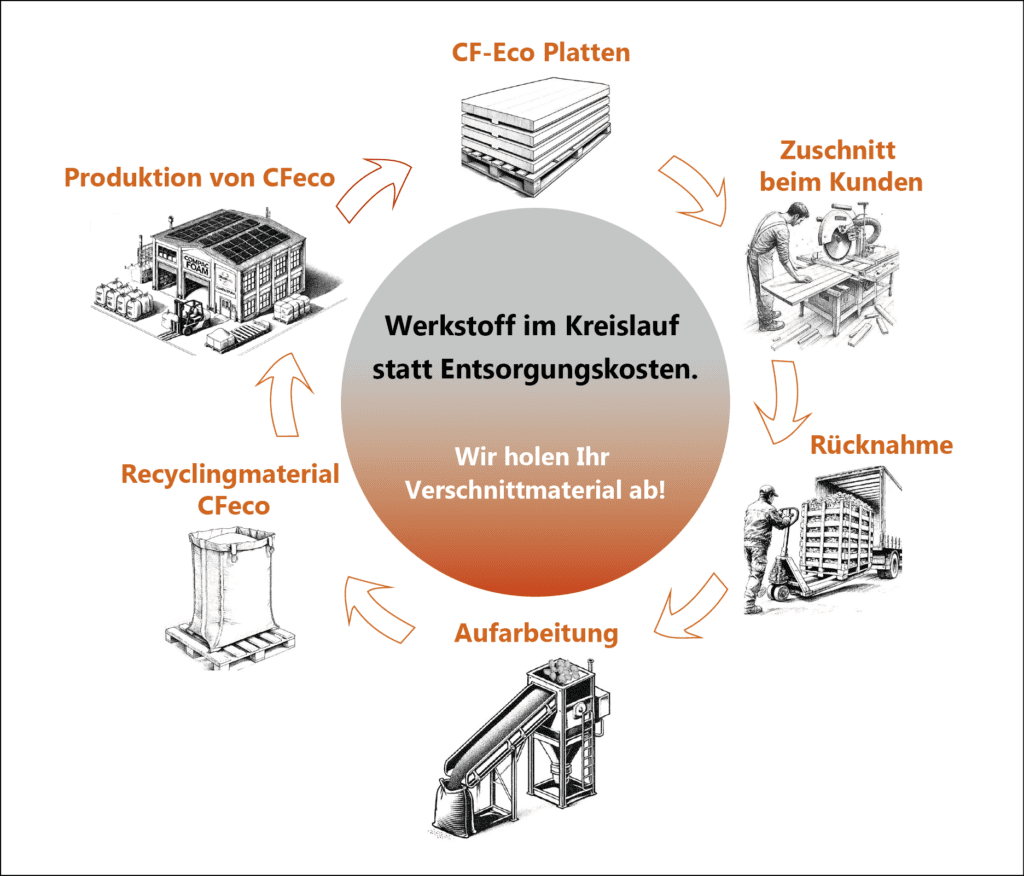

All products can be delivered in 100% recycled quality.

Videos.

Installation video on front wall installation,

standard

Installation video in front of the wall, special case:

Heavy loads1

Installation video in front of the wall, special case:

Heavy loads 2

Installation video on front wall installation, V-Fixx

(double-shell masonry)

Installation video on front wall installation,

Special case of steel construction

Correct sawing of construction insulation material

References.

Test mark.