LIFT & SLIDE SUBSTRUCTURE

ECONOMICAL AND STURDY.

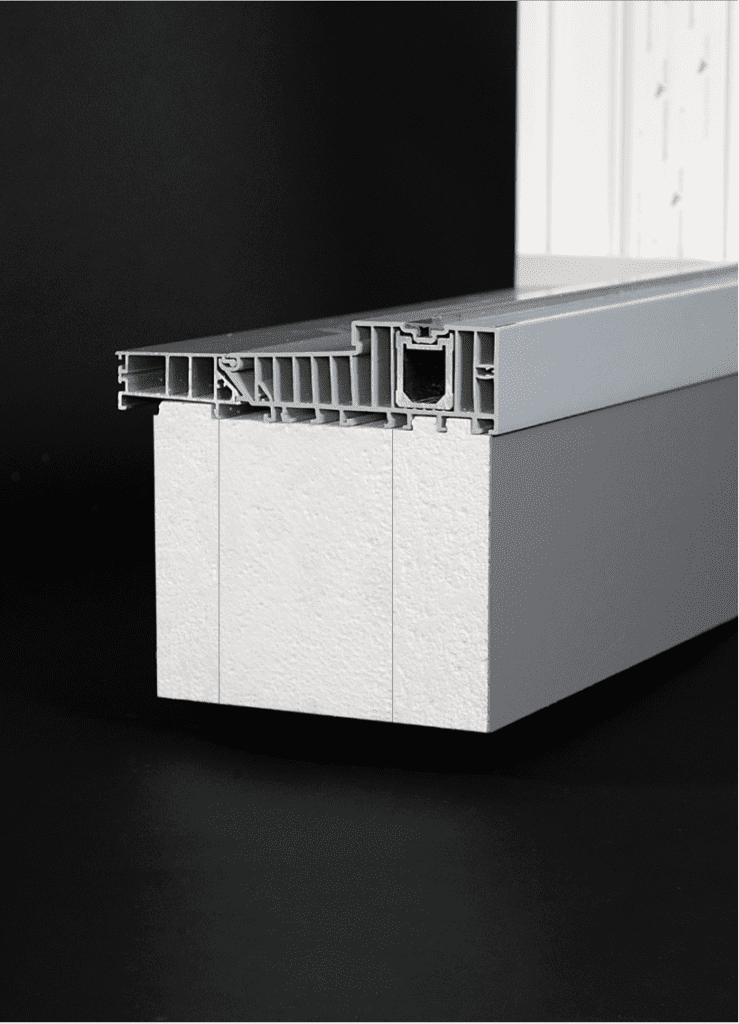

The Lift & slide support packer is a combination of two external structural support layers with a light, non- structural, insulating core. This combination reduces the overall weight of the packer, provides excellent ther- mal performance and the clever combination provides a cost saving. The two external structural sections pro- vide adequate support for the lift and slide door system and also allow the packer to be easily and securely fi- xed to the building substrate and the threshold profiles.

SPECIFICATIONS:

Supplied in standard lengths of 2350mm and in any length, to order, up to a maximum of 6000mm.

Can be supplied in any height, to order, up to a maximum of 400mm.

Can also be produced as a stacking packer variant which can be glued and screwed together on to achieve the required dimension.

Plates 2350x1160x40-220mm (L, W, thickness)

The surface can also be capped with a white or grey PVC-U external face.

Profiles are supplied with a purpose made contoured top face which fits the underside of the threshold profile. Any profile system can be accom- modated. Standard production details for Siegenia, Aluplast, Profine and Maco to name a few. Other systems available on request

SEALING DETAIL:

The external face must be sealed with a suitable sealing system. See

our data sheet for approved liquid waterproofing suppliers and products. Torch-on or heat gun applied bitumen sealing membranes can be used in accordance with the directions and recommendations on the sealing detail application sheet

TESTED ACCORDING TO ETB

TIMBER FREE MATERIAL

WILL NOT ROT

RESISTANT TO MOISTURE AND THE EFFECTS OF FREEZE THAW EXCELLENT INSULATION PROPERTIES

Sandwich core 2 base layer

CF eco

Thickness

140 mm

150 mm

160 mm

170 mm

180 mm

190 mm

200 mm

210 mm

220 mm

230 mm

240 mm

U-Value (W/ m2K)

0,29

0,27

0,25

0,24

0,22

0,21

0,20

0,19

0,18

0,17

0,16

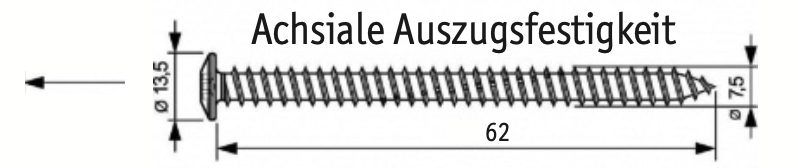

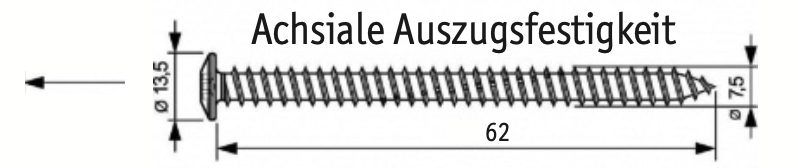

Screw pull out

resistance

825 N

Packing Shims in mm

max. glass panel load in kg

60×40

567,60

53×66

624,40

53×140

1324,40

53×170

1608,00

53×210

1986,40

Fire class

DIN 4102-1 / EN 13501-1

B1/E

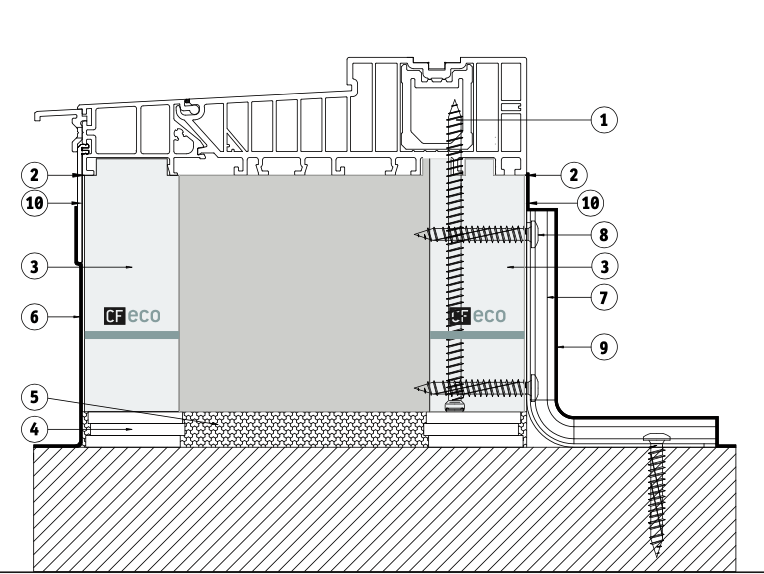

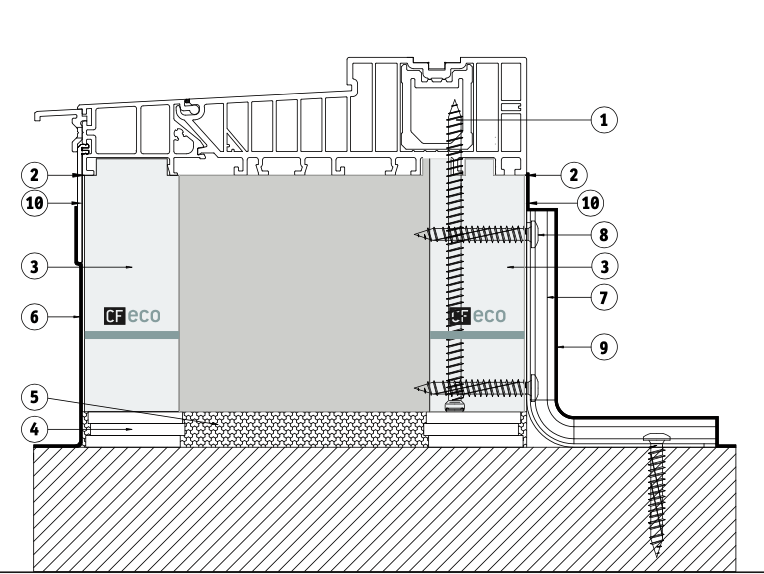

Technical drawings.

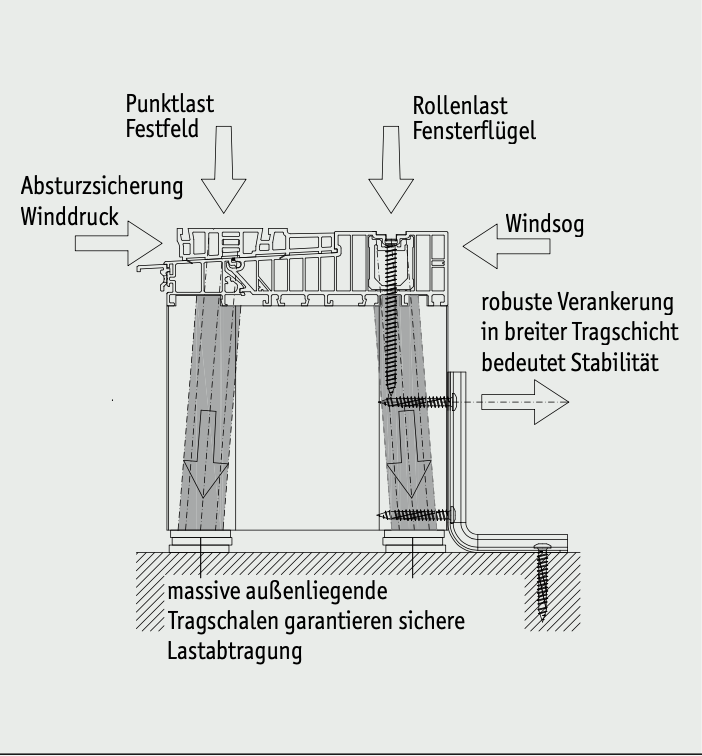

Installation variant with highly insulating substructure insulation profiles suitable for all lift-and-slide door thresholds.

> The two solid layers situated on the inside and outside of the threshold support material transfer the heavy moving loads of lift-and-slide doors into the sub structure of the building.

> The mounting brackets are also securely fixed into the structural base layer.

> Wind pressure, Wind suction, static and moving load forces are transferred through the support material to the substrate and the fixing brackets.

Test mark.